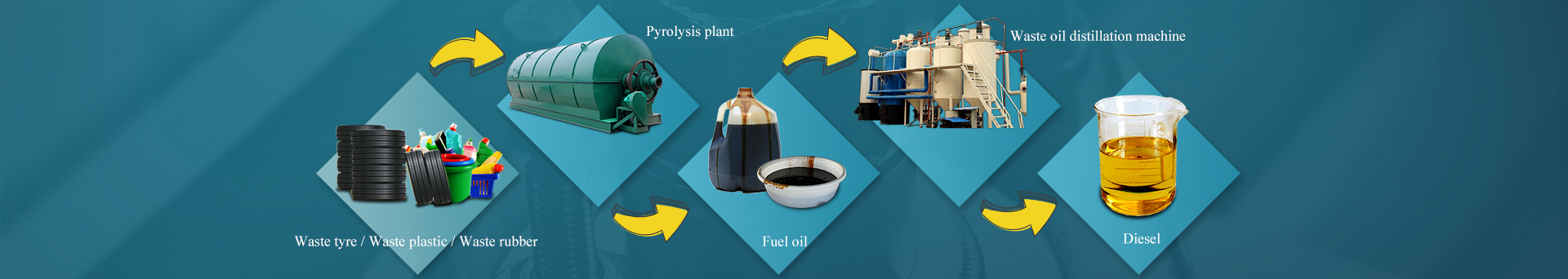

Production introduction of waste plastic to oil pyrolysis plant and plastic to diesel fuel oil distillation plant

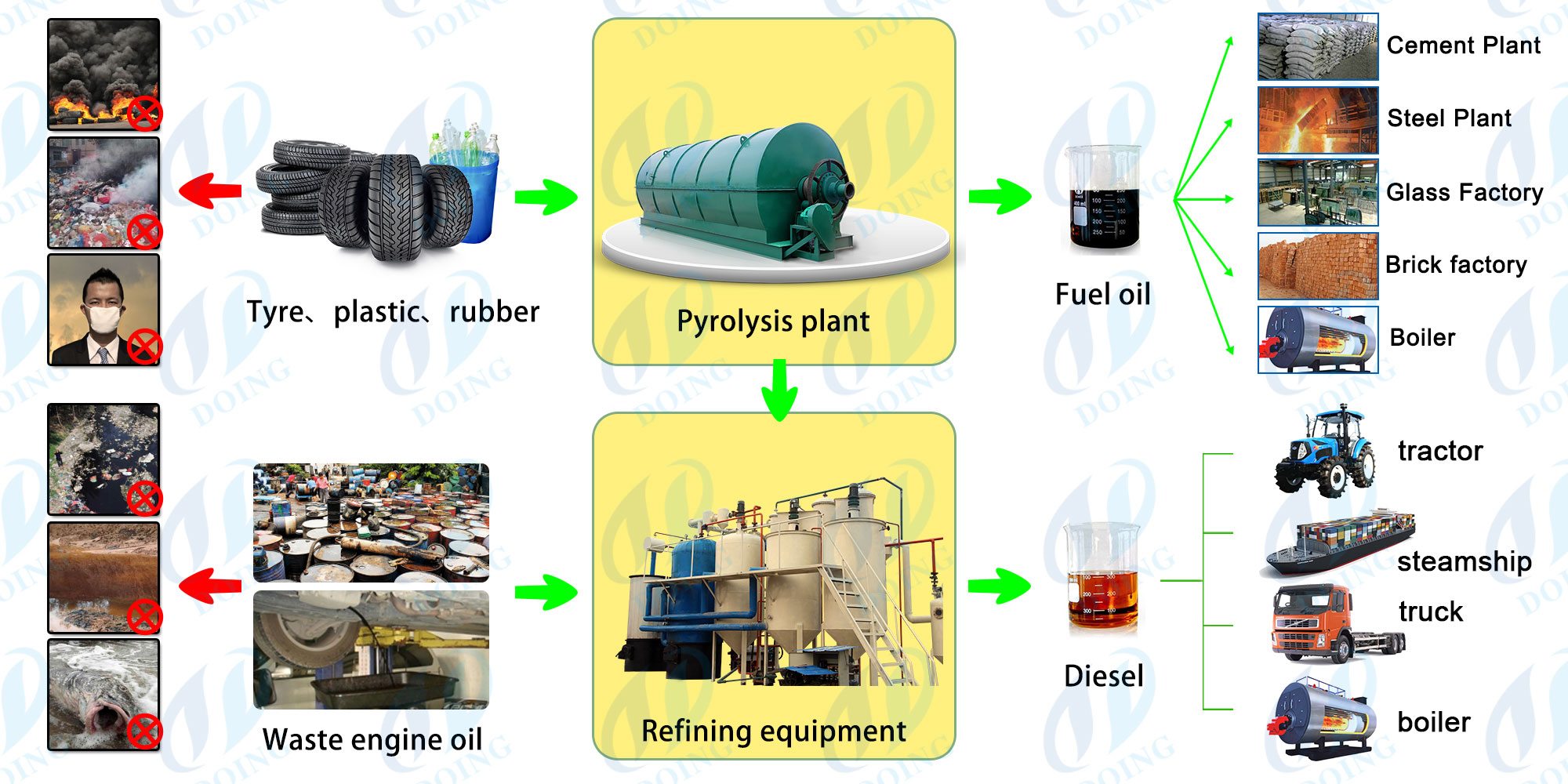

To solve the problem of waste plastic in a green way, instead of landfill or burning. With many years exploring and conquering, Henan Doing producting waste pyrolysis plants and waste oil distillation plants, waste plastic to oil pyrolysis plant can pyrolysis down of waste plastic to energy. The final product from waste plastic to oil pyrolysis plant is fuel oil, carbon black and steel wire. Fuel oil can be as fuel to heating, such as heavy industries, cement factory, steel milling factory, glass making factory, boiler factory etc. The oil we get from the waste plastic to oil pyrolysis plant can be futher distillate into diesel fuel oil. Diesel fuel oil is a very good diesel which is very close to common diesel. It can be used for tractors, trucks, diesel oil generators, and low speed engine like digging machine/road roller/loading machine and so on.

Waste plastic to diesel

Waste plastic to diesel

Working process of plastic to diesel fuel oil distillation plant

Plastic to diesel fuel oil distillation plant process

Plastic to diesel fuel oil distillation plant process

Plastic fuel oil will be heated into oil gas with indirect heating. Then oil gas will be cooled into diesel. With the processing of color and odor removal system, diesel quality will be improved a lot.

Main features of plastic to diesel fuel oil distillation plant

1. Fast.

The unique fast heating system is especially designed for shorten working time.

In market, mostly are horizontal reactor or old design for plastic to diesel distillation machine which take about 3-5days to finish one batch.

2. Easy slagging

Vertical reactor make slagging from bottom automatically and fast.

3. Energy saving

Fast heating system keep temperature even after slagging and you can use for next batch so is energy saving.

4. Safe

Strict quality control system and professional safety devices guarantee our plastic to diesel distillation machine running safely and win a good reputation from customers.

5. Environmental friendly

Professional dedusting systems ensure our plastic to diesel distillation machine runs zero pollution.

Technical parameters of plastic to diesel fuel oil distillation plant

| NO. | Items | Contents |

| 1 | Capacity | 5T/D, 10T/D, 15T/D, 20T/D |

| 2 | Raw material | Tire/plastic pyrolysis oil, waste engine oil |

| 3 | Structural form | Vertical |

| 4 | Outputs | Diesel, asphalt |

| 5 | Diesel yield | 80-85% |

| 6 | Operating pressure | Normal |

| 7 | Material of Reactor | Q245R boiler plate |

| 8 | Thickness of Reactor | 16mm |

| 9 | Safety standard | Pressure vessel standard |

| 10 | Total power | 24.5KW |

| 11 | Mode of cooling | Recycled water cooling |

| 12 | Required water | 40m3 for recycle use |

| 13 | Heating method | Recycled conduction oil heating with fuel heating |

| 14 | Discharge way | Automatically |

| 15 | Noise dB(A) | ≤85 |

| 16 | Running process | Semi-continuous |

| 17 | Delivery time | 20days |

| 18 | Weight | 20-50T (depends on the capacity) |

Feedback from customer

Pakistan Mr Asif plastic to diesel distillation machine

I’ve successfully tried plastic pyrolysis oil in the distillation machine. It took 7 hours finished 4T fuel oil processing. Result is better for plastic oil as raw material. Plastic diesel quality is good.