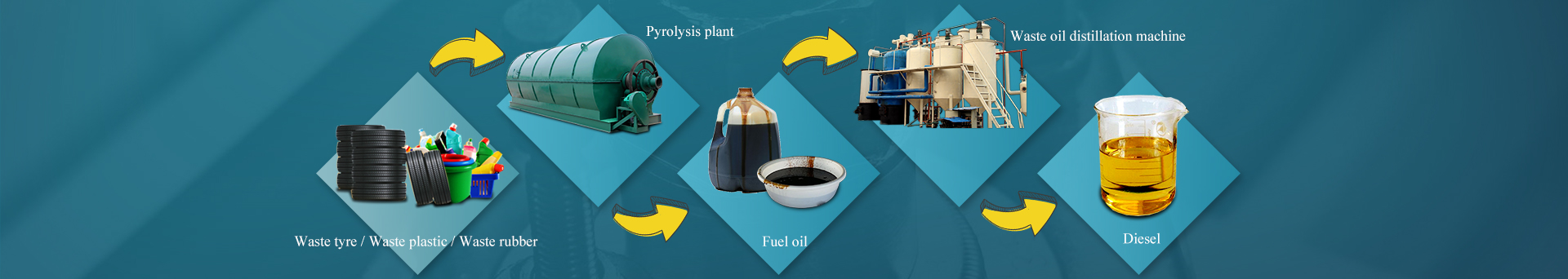

Production introduction of waste tyre to diesel plant

Waste tire is often called “black pollution”, because it not only easily causes fire, but also pollutes the environment. However, it is also a kind of valuable renewable resources for human beings. Through the use of waste tire oil pyrolysis plant to fuel oil manufactured by Doing company. We can get three kinds of final products: 45%-52% tyre fuel oil, 30% carbon black, 12%- 15% steel wire and 10% gas . They all have a wide range of applications. For example, the tire fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. There is also a little combustible gas producing in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

Waste tyre to diesel distillation machine

Waste tyre to diesel distillation machine

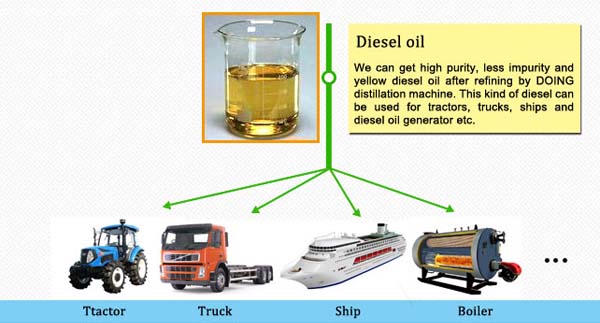

And we can use our DOING waste tyre to diesel distilation plant to distillate the tyre oil to clear diesel. DOING waste tyre to diesel distillation machine is specially made mainly as the auxiliary equipment of our waste tyre/plastic pyrolysis plant. It can refine tyre fuel oil and plastic fuel oil got from the pyrolysis plant into diesel oil. However, Except tyre oil and plastic oil, this oil distillation machine can also refine waste motor/engine oil into diesel. This diesel oil can be used for boilers, trucks, generators, and low speed engine like digging machine/road roller/loading machine and so on.The normal processing capacity for our distillation machine includes 3T/D, 5T/D ,10T/D and 20T/D.

Diesel application

Diesel application

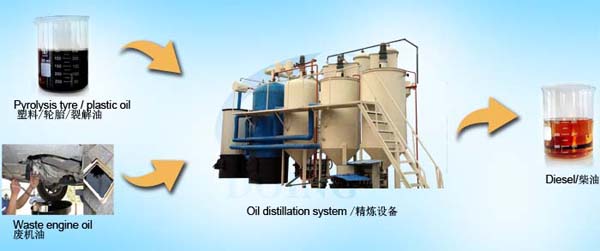

Feedstock& product of DOING waste tyre diesel distillation machine

The feedstock can be tyre pyrolysis oil, plastic pyrolysis oil, waste engine oil, etc, the final product will be diesel oil.

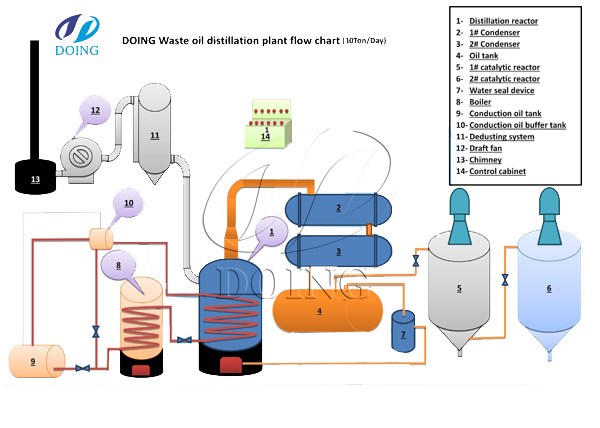

DOING waste tyre to diesel distillation machine

DOING waste tyre to diesel distillation machine

Working process of DOING waste tyre to diesel distillation machine

1. Put tyre oil/plastic oil/engine oil into distillation reactor with oil pump

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

Waste tyre to diesel distillation machine process

Waste tyre to diesel distillation machine process

Main feature of DOING waste tyre to diesel distillation machine

New tech DOING waste tyre to diesel distillation machine is always known for its high working efficiency, high oil output and high oil quality since its first day appearing in the market. Why DOING waste tyre to diesel distillation machine is the new tech? That is because DOING waste tyre to diesel distillation machine has the revolutionary changes on the design of distillation reactor and the heating method. New Tech DOING waste tyre to diesel distillation machine adopts vertical design distillation reactor and indirect heating by heating oil boiler, rather than the traditional horizontal design distillation reactor heated with open fire. The temperature of heating oil can reach 400℃,the distillation process can be finished very fast with the heat from the heating oil, meanwhile indirect heating can greatly prolong the reactor life. The traditional waste tyre to diesel distillation machine heated directly by open fire, and it will take very long time to finish the distillation process and since it uses open fire heating, the reactor body will have short life time, besides, the distillation reactor is horizontal design, it is not easy to do the residue slagging. Anyway , DOING New Tech waste tyre to diesel distillation machine has many obvious advantages over the traditional one.

Technical parameters of DOING waste tyre to diesel distillation machine

| NO | Items | Contents | ||||

| 1 | Equipment type | Boiler | Distillation Reactor | Heating furnace cover | Degumming reactor | Odor removal reactor |

| 2 | Application | Heating heat transfer oil | Distill raw material | Heat preservation | Degumming | Remove odor |

| 3 | Structural form | Vertical or Horizontal | Vertical | Vertical | Vertical | Vertical |

| 4 | Raw material | Heat transfer oil | Crude oil/ waste oil | Crude oil/ waste oil | Crude oil/ waste oil | |

| 5 | Operating pressure | Normal | Normal | Normal | Normal | Normal |

| 6 | Material of reactor | Mode:YYQW-240 | Q245R | Q235 | SS-304 | Q235 |

| 7 | Thickness | 16mm | 6mm | 6mm | 6mm | |

| 8 | Mode of heating | Direct | Indirect | None | None | None |

| 9 | Size | Φ1700mmx2200mmx16mm | Φ2000mmx1300mmx6mm | Φ1300mmx2000mmx6mm | Φ1300mmx2000mmx6mm | |

The customer feedback

My waste oil distillation plant purchased from DOING is running very well now. I’ve got diesel oil and sell it to boiler factory. I am planning to increase the processing capacity and I will come to order one 10ton capacity distillation machine from you next year.

My waste oil distillation plant purchased from DOING is running very well now. I’ve got diesel oil and sell it to boiler factory. I am planning to increase the processing capacity and I will come to order one 10ton capacity distillation machine from you next year.