FAQ

What’s waste oil to diesel distillation plant?

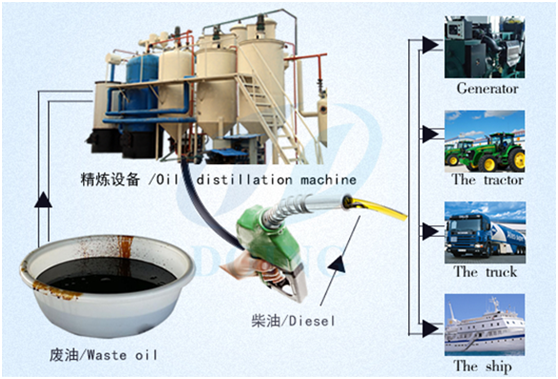

Waste oil to diesel plant, firstly, we also name it as waste oil distillation plant, which is specially designed for refining crude or heavy or waste oil to clean diesel through a distillation & decolorization & deodorization system. The end products we get from the process is diesel and asphalt.

What kind of waste oil could be processed by the waste oil to diesel distillation plant?

- 1) Waste engine oil

- 2) Used motor oil

- 3) Tyre pyrolysis oil

- 4) Plastic pyrolysis oil

What’s the use of the end products?

1) Diesel: The diesel product produced from the distillation plant, is a kind of clean fuel, similar functions like normal diesel used in our daily life, only a few features are little different. Usually we suggest customers to use this diesel product in heavy machinery, like farm machinery, heavy trucks, heavy fuel generators, etc. Also it could be directly used as heating fuel in any industrial factories without any concern.

2) Asphalt: The asphalt product we get from the distillation process is the residues left inside the reactor after extract the light oil. It’s very heavy, like oil sludge, with the similar function like asphalt. So it could be directly used as asphalt in construction field, like road building. Also it could be sold to the asphalt refineries for further refining. Another solution is, if you have pyrolysis plant, you could put the distillation residues to the pyrolysis machine for further processing, thus to make fully oil extraction.

What’s the working process of the waste oil to diesel distillation plant?

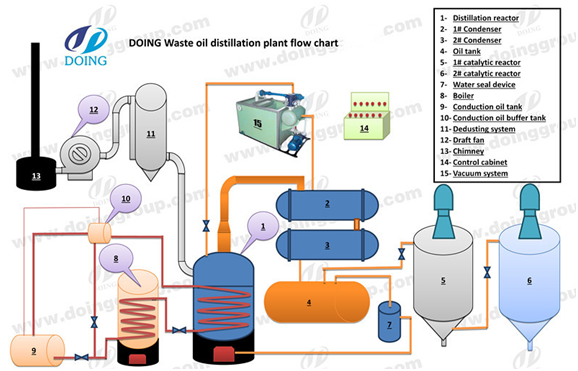

1) Heating and distillation:

Firstly, we pump the waste or crude oil to the distillation reactor, then start heating till oil become oil gas come out.

2) Decolorization and deodorization:

For this section, now we have two solutions.

Solution I: Oil gas come out from the distillation process would go to a condenser system to be cooled down to liquid oil at first, then mix with chemicals to remove wax and gum, thus to remove heavy color and smell from the oil, finally to get the clean fuel, which is diesel;

Solution II: Oil gas come out from the distillation system would be cut into different fractions by temperature control. Firstly, in lower temperature heating, we get the light fraction out and make it directly go to the condenser system to be cooled down to light oil. Then we increase the heating temperature to get the heavy fraction out from the waste oil, and make it go through a catalytic system to be cracked and absorbed color and odor, thus to get the clean fuel.

How is the profit of the waste oil to diesel distillation plant?

Here we take waste engine oil as an example, and make a profit analysis for you as below:

(In the ROI analysis, we take the processing capacity as 10T/D, heating fuel is the diesel product we produce directly from the distillation plant, and all the costs and prices are come from Chinese market.)

| ROI Analysis For 10T/D Waste Oil to Diesel Project | |

| Running Cost / Day | |

| Waste engine oil | 10Ton * USD265/Ton = USD2650 |

| Heating fuel (Diesel) | 0.6Ton * USD700= USD420 |

| Catalyst | USD100 |

| Electricity | USD60 |

| Water | Water is for circulation use, no consumption |

| Worker | 2 * USD25 = USD50 |

| Income / Day | |

| Diesel | 8.5Ton * USD700 = USD5950 |

| Oil sludge (Asphalt) | 1Ton * USD200 = USD200 |

| Profit / Day | USD2870 |