Continuous pyrolysis of plastic plant

Continuous pyrolysis of plastic plant

DOING Continuous pyrolysis of plastic plant with high efficient and environmentally friendly. No pollution to air, water and earth.

The two keys of continuous pyrolysis of plastic plant are reactor and cooling system.

Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

Plastic to oil line cooling systems decides oil output. There are two steps for cooling. Cooling pipe is the first step. The second is condenser. Its inner have 61 pipes in one condenser. The total cooling area is 100㎡. This will guarantee you a high oil yield. The reasonable design has a direct relationship with the oil output.

Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

Plastic to oil line cooling systems decides oil output. There are two steps for cooling. Cooling pipe is the first step. The second is condenser. Its inner have 61 pipes in one condenser. The total cooling area is 100㎡. This will guarantee you a high oil yield. The reasonable design has a direct relationship with the oil output.

Technical data of continuous pyrolysis of plastic plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

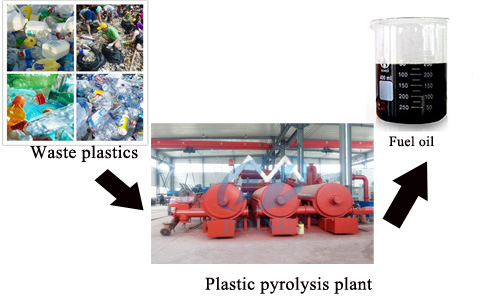

Application of continuous pyrolysis of plastic plant

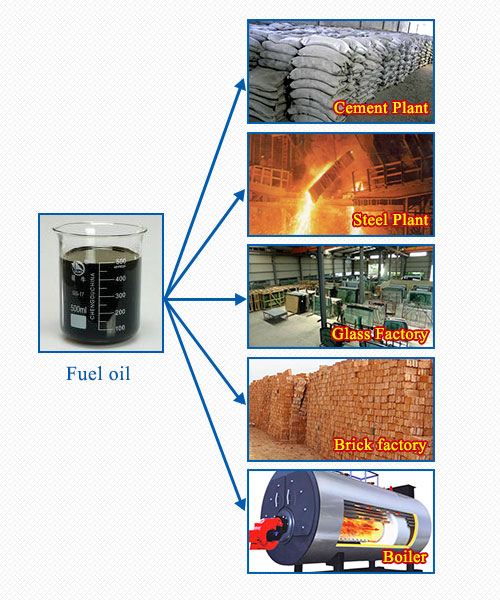

Fule oil application of continuous pyrolysis of plastic plant

1. The continuous pyrolysis of plastic plant is widely used by recycling center, waste plastic recycling company, and Eco-protect Company.

2. The final product from continuous pyrolysis of plastic plant is fuel oil, diesel, carbon black and steel wire. Fuel oil can be as fuel to heating, such as heavy industries, cement factory, steel milling factory, glass making factory, boiler factory etc. Diesel oil can be used for tractors, trucks, and diesel oil generators. Carbon black can sell to cement factory, also can pellet them to heating the machine