Home>FAQ>Waste oil to dieselHow do we ensure the safety of our tire recycling machine when operation?

Home>FAQ>Waste oil to dieselHow do we ensure the safety of our tire recycling machine when operation?

How do we ensure the safety of our tire recycling machine when operation?

How do we ensure the safety of our tire recycling machine when operation?

1. What’s the safety design of our tire recycling machine which can buffer the pressure itself?

From the below picture, you can see our reactor has ellipsoidal head, which is an obvious symbol for pressure vessel. The ellipsoidal head has a strong tension and buffering when pressure generated. And it can better connect with the reactor body, therefore cannot be easily cracked under high pressure.

Boiler head of Reactor

2. How can we avoid the high pressure generated before accident happens?

Below you can check there are some safety devices of our tire recycling machine, such as pressure gage, pressure valve, alarm bell, temperature panel. If wrong operation cause high pressure, the alarm bell will ring immediately. If there are workers beside, the workers can open the pressure valve manually. If there is no worker beside, the pressure valve can open automatically.

Safety device

3. How to prevent oil gas flow back to keep safe pressure of the whole system?

For tire recycling machine, after heating there is oil gas produced and run through all the system of the machine to be cooling down to liquid oil. But how can we keep the oil gas only go ahead cannot go back to the reactor, and then cause accident? If any workers have any wrong operation and make the oil gas flow back, there would be very dangerous. So to prevent this dangerous situation happen, we designed the following safety devices: vacuum system, oil-water separator and water seals.

Safety device 02

4. Do we have safety production certificates for tire recycling machine?

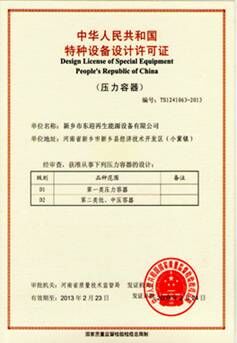

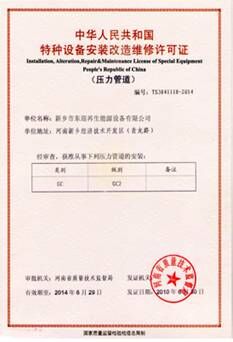

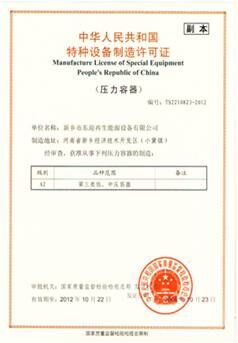

1) Certificates for pressure vessel design and production:

Safety production certification

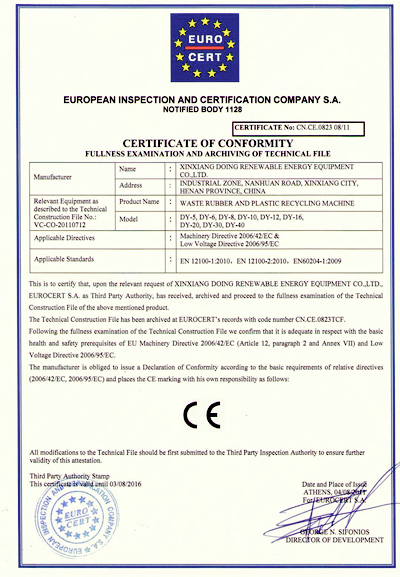

2) CE certificate: