How much tyre does it take to make a ton of diesel?

According to the feedback of Doing Company’s customers, it generally takes about 2.5 tons to 3.5 tons waste tyres to make a ton of diesel. But the tons of tyre it needs to make a ton of diesel is not always the same, because it is influenced by many factors, such as the type and quality of the waste tyre, the technology and operation of the waste tyre to diesel recycling machines, etc. Please keep reading and Doing Company will introduce it to you in detail.

First of all, we need to know that obtaining diesel from waste tyre will need waste pyrolysis plant and refinery plant working together. It means to get pyrolysis fuel oil from waste pyrolysis plant first and then obtain diesel through the further refinery of our waste tyre pyrolysis fuel oil.

Waste tyre to diesel machine

Waste tyre to diesel machine

The oil outputs of waste tyre pyrolysis plant vary from 35%-50%, which mainly depends on the type and quality of waste tyres. For example, small car tyres, motorcycle tyres and bicycle tyres will have an oil yield around 35%, but for truck tyres or big OTR tyres, the oil yield can be as high as 50%, which can be also understood that DOING's 10ton capacity waste tyre pyrolysis plant can produce 3.5 tons-5 tons pyrolysis fuel oil in a day.

And the diesel output of pyrolysis oil refinery plant is as high as 80%, so from 3.5tons -5 tons tyre pyrolysis fuel, we can collect 2.8 tons-4 tons diesel fuel. Therefore, from the above oil output of our waste pyrolysis plant and waste oil refinery plant, we can calculate how much tyre is needed to make a ton of diesel.

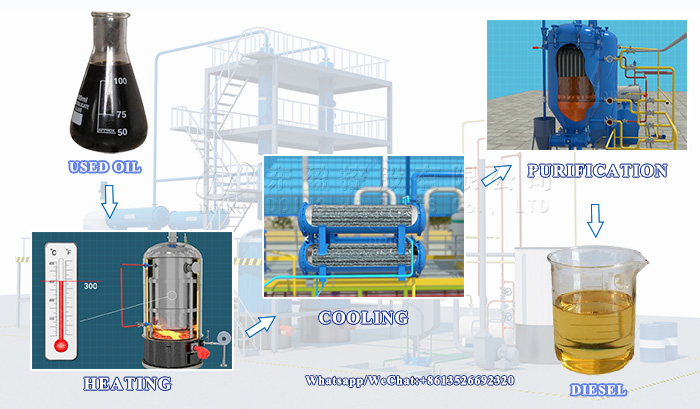

Waste oil refining process

Waste oil refining process

Besides that, waste tyre pyrolysis plants with different technical processes and configurations will produce different amounts of fuel oil, even the season and machine operators sometimes also have impacts on how much oil the pyrolysis plant can produce from old tyres.

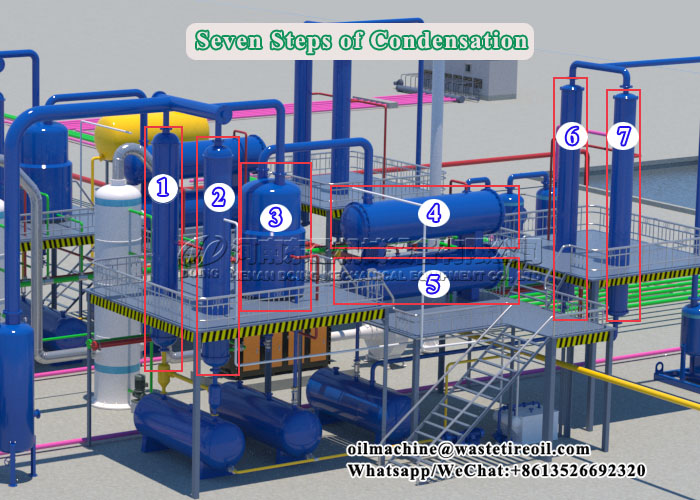

The cooling effect of pyrolysis plant influences the conversation rate from waste tyre to fuel oil a lot, pyrolysis plant with good technical process is sure to have a strong gas cooling system, which means higher oil yield. And the correct operation means to have a well-control of the pyrolysis temperature, which will ensure all of the oil gas can be condensed and no wasting. So a skilled pyrolysis plant operator is indispensable for you to get more oil from old tyres.

Cooling sytem

Cooling sytem

Doing Company has customized the waste tyre to diesel pyrolysis plants and refinery plants for customers in more than 90+ countries and regions, and our high quality waste tyre to diesel recycling machines and all around technical support&operation instruction have helped customers make great money from the waste tyre recycling business. If you are interested in our machines and professional waste tyre recycling business solutions, please don’t hesitate to contact Doing Company.