How to dispose the waste tires to fuel oil?

Waste tire

According to reports, at present, the number of used tires produced in China has reached 40 million to 50 million. For the treatment of used tires, from a global perspective, since the early 1990s, mainly buried, stacked or incinerated. But experts believe that these methods do not help to solve "black pollution." Because used tires do not naturally degrade even if they are buried for 100 years, long-term open-air stacking not only occupies a large amount of land, but also easily breeds mosquito-borne diseases and is also prone to fire.

DOING waste tire pyrolysis plant

Waste tires pose a great threat to the environment. How do you deal with these stacked waste tires? How to deal with these used tires will not cause environmental pollution? In some areas, some people use these accumulated waste tires to pyrolysis their oil. Is this method desirable? Will it pollute the environment? The newly developed waste tire pyrolysis plant can effectively treat these waste tires. The waste tire pyrolysis plant uses these accumulated waste tires as raw materials, and undergoes a series of reactions of pyrolysis, and the obtained products are pyrolysis oil, carbon black and steel wire. The entire pyrolysis process is environmentally friendly and non-polluting. So how do you dispose these used tires?

Waste tire pyrolysis plant raw materials: used tires

The following is the process flow of waste tire pyrolysis plant:

Waste tire pyrolysis plant working process

1. Feeding takes 1-2 hours. Tires below 1.4 meters can be directly fed into the whole tire. Large tires need to be cut first and then fed.

2. Heating takes about 10 hours, and oil and gas are generally produced when heated to 2 hours.

3. Cooling, the oil and gas is condensed into oil through a cooling system;

4. Exhaust gas recovery and utilization, in the process of heating and cracking, in addition to oil and gas, there will be some flammable but non-condensable gas, which we call "exhaust gas", this gas can be directly recovered for heating cracking reactor to save fuel;

5. Carbon black and steel wire slag, the end of the pyrolysis plant working process, after the oil and gas is discharged, it is necessary to discharge the residual material inside the reactor to carry out a new pyrolysis palnt working process, which mainly includes the steel wire for making carbon black of the tire.

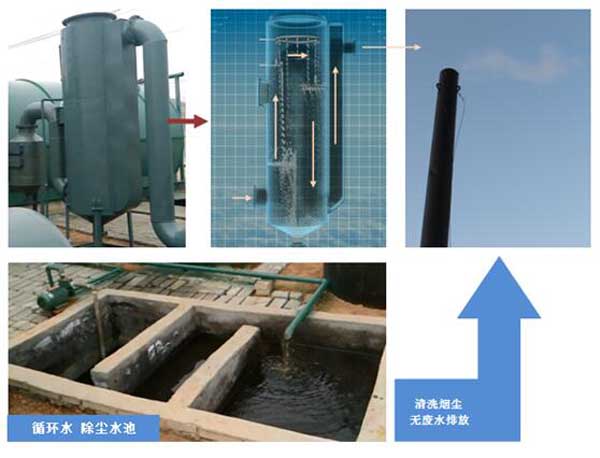

The waste tire pyrolysis plant treats the three wastes generated during the cracking process:

Waste tire pyrolysis plant environmental system

1. Exhaust gas

The waste tire pyrolysis plant is fully burned by the safety device water seal and gas nozzle, which not only eliminates the exhaust gas pollution, but also saves a lot of fuel; the desulfurization dust collector can be used for the soot emission, and the soot emission can reach the relevant standard of GB 13271-2001.

2, waste liquid

Waste tire pyrolysis plant oils will produce some weakly acidic wastewater during processing (about 50 kg of wastewater per ton of oil produced). After adding neutralization to the neutralization, the neutral wastewater is filtered through three stages to achieve harmlessness, and then discharged to a dedicated evaporation processor (the heat source of which uses the flue heat of the main processor) to evaporate, and more professionally Wastewater treatment plant).

3. Waste solids

After the waste tire is catalyzed by thermal cracking, there will be some solid residue, which accounts for about 5% to 10% of the weight of the used tire. Its main component is crude carbon black. It can be used as a raw material for the production of industrial carbon black, or as a raw material for the manufacture of fly ash bricks (an environmentally friendly building material) by mixing with fly ash from coal-fired power plants.

Waste tire pyrolysis plant product use:

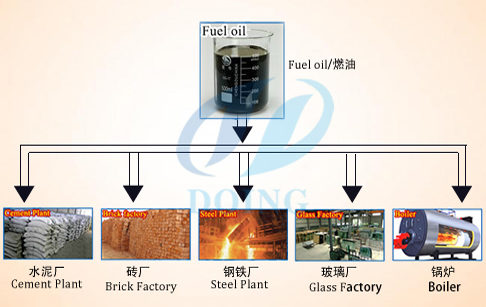

Fuel oil application

Fuel oil (45%-55%)

1. Sold as fuel to cement plants, glass factories, ceramic factories, power plants, steel mills, boiler plants, etc.

2. For heavy oil generators to generate electricity.

3. Decolorization and deodorization equipment deep processing fuel oil into diesel oil. Tire diesel can be used in trucks, tractors, etc.

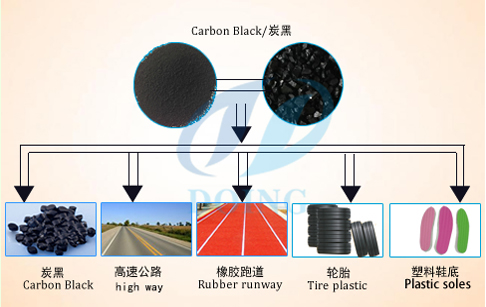

Carbon black (30%-35%)

Carbon black application

1. Made of spherical carbon black and carbon black briquettes for heating and burning.

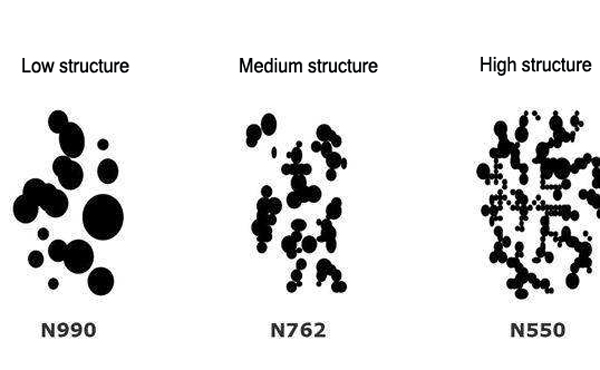

Carbon black structure

2. Grind to N990, N762, N550 or N6660 for the tire manufacturing industry.

3. Processed into a color master and sold to the plastics industry.

Steel wire (10%-15%)

1. Sell directly to the steel plant.

2. Provide a more profitable wire handling solution that allows wire prices to reach $460 per ton.

Combustible gas (8%-10%)

1. Recycle to the furnace and heat the reactor to save coal/wood/fuel oil/natural gas.

2. Store the remaining exhaust gas and use it to heat the reactor in the future.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications