Convert plastic to fuel pyrolysis machine

Convert plastic to fuel pyrolysis machine is DOING company based on the principle of pyrolysis designed and manufactured. Convert plastic to fuel pyrolysis machine can turn waste plastics into pyrolysis oil, carbon black and some combustible gases.

Convert plastic to fuel pyrolysis machine

Convert plastic to fuel pyrolysis machine

The conversion from plastics to fuel will tap into the surplus value of countless waste plastics around the world.

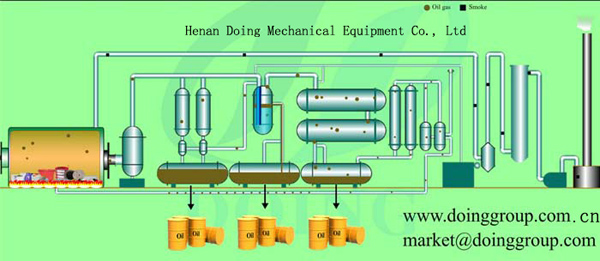

The process of convert plastic to fuel pyrolysis machine is described as follows:

1. Waste plastics are fed by an automatic feed machine into the reactor of convert plastic to fuel pyrolysis machine, which is then heated with fuel. When the temperature rises above 200 degrees, oil gas will be produced in the reactor.

2. Oil gas enters the condensing system through the pipe. After cooling by a three-stage condensing system, the oil gas is liquefied into heavy oil, which is collected in the tank.

3. The collected heavy oil is desulfurized and degreased to obtain plastic pyrolysis oil.

4. Carbon black generated in the pyrolysis process is discharged through the underground closed slag discharge channel. This way of collecting carbon black avoid carbon black emissions in the process of chatter and cause secondary pollution to the air.

5. Use the dust removal system to deal with the flue gas generated in the pyrolysis process to remove the solid particles contained in the flue gas. If coal, wood or heavy oil is used as fuel, the smoke produced will be relatively high. In view of this situation, DOING company specially developed a pulse dry dust removal device. Both devices can eventually achieve smoke-free emissions.

Plastic to fuel conversion process

Plastic to fuel conversion process

As a leading manufacturer and supplier of convert plastic to fuel pyrolysis machine in China, DOING company's convert plastic to fuel pyrolysis machine has some unique advantages:

1. Convert plastic to fuel pyrolysis machine can increase the oil production of waste plastics by 5%;

2. The combustible gas produced by convert plastic to fuel pyrolysis machine can be used to heat the reactor, saving 30%-40% of the fuel cost.

3. The operation of convert plastic to fuel pyrolysis machine is 100% safe.

4. There are different types of convert plastic to fuel pyrolysis machine. Customers can choose the appropriate equipment according to the budget and actual needs.

Convert plastic to fuel pyrolysis machine in operation

Convert plastic to fuel pyrolysis machine in operation

Technical parameter of Convert plastic to fuel pyrolysis machine

| Technical parameter of plastic to fuel conversion process | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Rawmaterial | motor oil,wastetirecrudeoil,plasticcrudeoil |

| Structureform | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operatingpressure | Constantpressure |

| Heatingmaterial | Coal,charcoal,fuelgas,fueloil |

| Averageout-putoilrate | 95% |

| Materialofreactor | 4 reactor with different material |

| Thicknessofreactor | 18mm |

| Modeofcooling | Recycled watercooling |

| Powerintotal | 20Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Convert plastic to fuel pyrolysis machine can get 45-50% flammable oil, 30% carbon black and 5% flammable gas.

They are widely used in different fields:

1. plastic oil can be widely used in iron and steel, boiler plants, ceramics, electric power or chemical industry or hotels, guesthouses and other industries fuel oil, or generator sets.

USES of pyrolysis oil

USES of pyrolysis oil

2. Carbon black can be used as clay brick or fuel.

3. Non-condensable combustible gas can be recycled and used to heat the reactor.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications