Waste tyre disposal equipment with environmental friendly

Waste tyre disposal equipment with environmental friendly

How is tyre recycled, let’s see the pyrolysis process of waste tyre disposal equipment with environmental friendly:

First step, make the reactor rotate clockwise 0.4 per minute, put raw materials into reactor automatically, close the feeding door tightly.Second step, burn the fuel materials (like coal, wood, natural gas, oil etc) in the furnace. The reactor will be heated slowly. When the temperature reaches nearly 180℃, the oil gas will come out and then go to the cooling system and liquefying to oil. Some incondensable gas which can’t cool down will flow to furnace through a pipe which can be used to heat the reactor.

In this way, you can save much more energy as you use energy for heating only in the first 2 hours. After the first 2 hours, the main fuel is gas. After pyrolysis, all the oil gas will come out from reactor, the temperature will fall down. Then make the rotate anticlockwise, carbon black discharging begins. Last step, when the temperature falls to 100℃, worker can open the reactor door and take steel out.

Main Feature of waste tyre disposal equipment with environmental friendly:

1. 100% waste tire recycling.

2. Environmental friendly: No chemical ingredients are used during processing. No soil, water and air pollution is observed during and after the process.

3. Generates lots of valuable products out of waste, all of the outlet products can be used as industrial raw materials with high value.

4. Apply the most advantage waste tyre recycling technology in the world.

5. The system creates an alternative source of energy to replace petroleum products and natural gas.

6. We supply plants with capacities of 5 ton /day to 10 ton/day.

| Technical parameter of waste tyre disposal equipment with environmental friendly | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre disposal equipment with environmental friendly | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

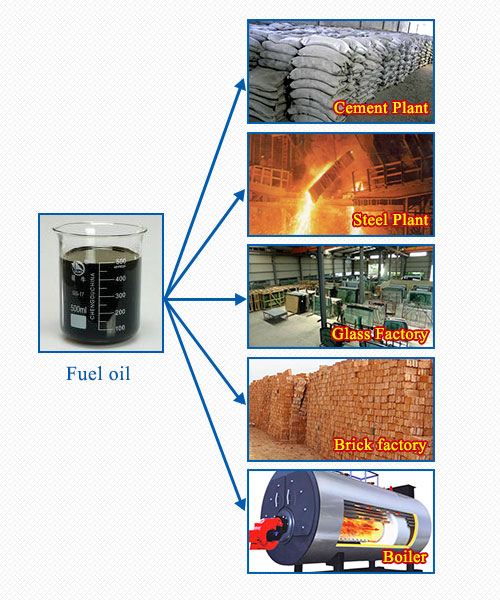

Tyre oil usage from waste tyre disposal equipment with environmental friendly

Product from waste tyre disposal equipment with environmental friendly

application as below:

1. Tire crude oil usage (where need the oil as fuel)

A. power plant factory B. glass factory C. cement factory D. ceramic factory

E. aluminum factory F. boiler factory G. central heating factory H. painting factory

2. Carbon black usage

As the waste tire carbon black there is ash inside so this quality is not so good. Until now our technology can use some ways to make the carbon black to briquette, which can be sold as the industry coal.

3. Tire wire steel usage

This can be sold to the steel making factory.

4. The waste gas (CH4, C2H6, C3H8, C4H10 and H2)

As these gas cannot be cooled under the normal pressure, besides they are all combustible gas, which is dangerous to storage. After it produces we let the gas back to the combustion system to burn as energy. This will safe and save your fuel cost.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications