Waste tyre oil to diesel recycling plant

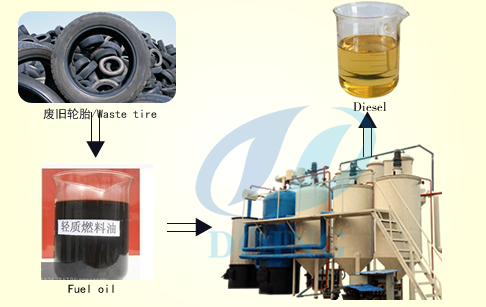

Waste tyre

With the development of society, our daily life is full of rubber products, such as tyre, shoes and so on. On one hand, they make our life convenient, on the other hand, if not be treated directly, they will cause a lot of trouble. We Doing group as the professional waste tyre pyrolysis plant supplier, it devoted to meeting the demands of all the customers.

Waste tyre pyrolysis plant

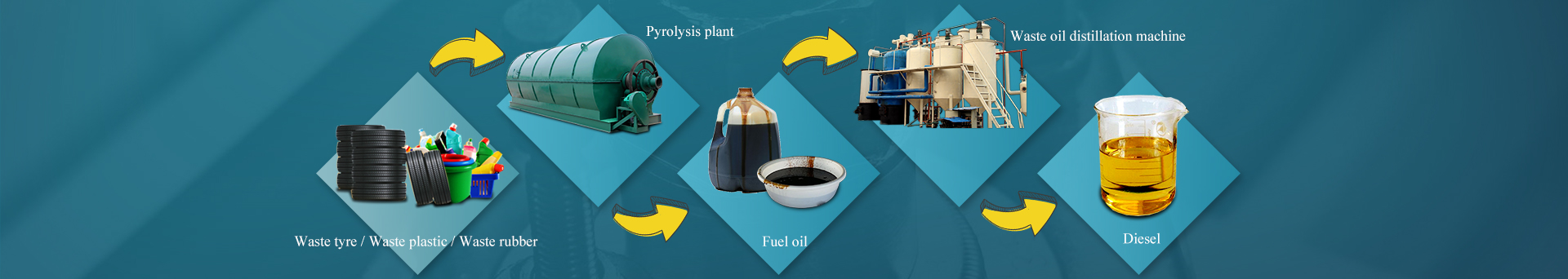

Waste tyre oil to diesel ,first ,the waste tyre pyrolysis plant convert waste tyre to fule oil ,than the waste tyre oil will be refiner by waste tyre oil to diesel recycling plant.

Waste tyre oil to diesel recycling plant

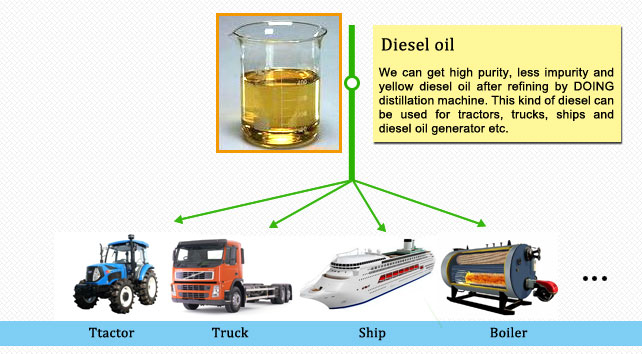

Waste tyre oil to diesel recycling plant can turn waste tyre oil to a high quality diesel. This waste tyre oil to diesel recycling plant not only applied to tyre oil also can use for plastic oil and waste engine oil. the final oil-diesel can be used for tractors, trucks, ships and generator power etc.

Waste tyre oil to diesel recycling plant

If you want to buy waste tyre oil to diesel recycling plant, below information should be know:

• 100% waste tyre oil recovery is achieved (no churn left after the process)

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective tire oil to diesel refining plant technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tyres oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

• During and after the process; no soil, water or air pollution is observed.

• The most cost-effective tire oil to diesel refining plant technology in the world.

• Raw material (waste tyre) is cheap and easy to provide. These are the by-products of tyre production.

• The process can be applied to plastic oil and waste engine oil.

• Vertical structure form, easy for cleaning and maintenance.

• The system creates an alternative source of energy to replace petroleum products and natural gas.

• System gives the opportunity to governments and local administrations to deal with the waste tyre problem to a great extent.

• System prevents the spread of diseases caused by waste tyres oil.

• We deliver plants with capacities of 5 ton to 50t/day and its multiples.

• The process of distillation has duration of 15 to 18 hours, depending on the quality of waste oil. Also it can work day and night. No need to stop.

| Technical parameter of waste tyre oil to diesel recycling plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tyre oil, waste engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

| Raw material | output |

| Waste tyre oil | 85%-90% |

| Waste plastic oil | 95% |

| Waste engine oil | 86%-90% |

Diesel engines in trucks, trains, boats, and barges help transport nearly all the products people consume. Diesel fuel is commonly used to fuel public buses and school buses.and diesel fuels most of the farm and construction equipment.

The construction industry depends on the power provided by diesel fuel. Diesel are able to do demanding construction work, like lifting steel beams, digging foundations and trenches, drilling wells, paving roads, and moving soil safely and efficiently.

The military uses diesel fuel for tanks and trucks because diesel is less flammable and less explosive than other fuels.

Diesel is also used in diesel engine generators to generate electricity. Many industrial facilities, large buildings, institutional facilities, hospitals, and electric utilities have diesel generators for backup and emergency power supply. Most remote villages use diesel generators for their electricity.

Prev: Waste tyre oil to diesel distillation plant

Next: Nothing

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications