Waste tyre recycling plant to fuel oil and carbon black

Waste tyres to oil recycling plant is a very hot and highly profitable green project, which can convert waste tyres to treasure (45% fuel oil, 35% carbon black, 15% wire steel and 5% syn-gas), which have wide applications and a large market.

Applications of obtained fuel oil and carbon black

Applications of obtained fuel oil and carbon black

Fuel oil: a kind of heavy oil, which can be used in some heavy oil machinery, such as cement plant, steel plant, glass plant, brick plant, etc., and heavy oil generator, boiler heating, etc.

Carbon black: a good heating fuel with high calorific value of about 7000 kcal/kg, can be converted into pellets with the briquette machine or make further refining to used as paints, etc.

DOING Mechanical has been dedicated to the research & development of the green pyrolysis technology for more than 14 years. And DOING waste tyre recycling plant project has spread all over the world, such as India, Mexico, Russia, America, Brazil, South Africa, Poland, Australia, Canada, Indonesia, also including EU countries where environmental requirement is very high, like France, Germany, Portugal, Romania, Netherlands, Czech Republic, etc. DOING Mechanical is also a well-known manufacturer in the Chinese pyrolysis industry, owning our own manufacturing factory to provide high quality equipment for our customers. And as the National High Technology Enterprise in China, in addition to obtaining a number of utility patents and invention patents, DOING fully continuous pyrolysis machine also gained prestigious recognition by securing a place in the 2024th Catalogue of Energy-saving, Water-saving, and Solid Waste Comprehensive Utilization Technologies and Equipment.

Projects display of DOING waste tyre recycling plants

Projects display of DOING waste tyre recycling plants

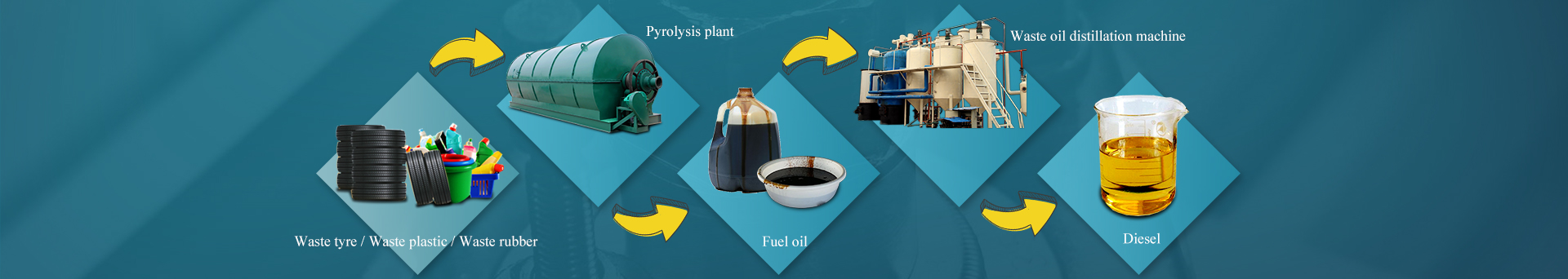

Waste tyre recycling plant is also called waste tyre pyrolysis machine. While pyrolysis is a process of molecular breakdown where larger molecules are broken down into smaller molecules. In the process of waste tyre recycling plant, the polymer waste is not burned, instead it is broken down into usable finished products, long chain polymer is broken down into smaller chains of Hydrocarbon Gas and Pyrolysis Oil(fuel oil). The following is a brief display of the work process of waste tyre recycling plant via 3D video:(After further processing of oil distillation machine, this pyrolysis oil can be changed into diesel oil which can be directly used for diesel oil generators, tractors and trucks, etc.)

For tyre waste management, pyrolysis is a better alternative compared to incineration or dumping. Incineration is burning of waste which leads to loss of valuable energy from polymer waste. Dumping waste is known to cause land pollution. While for pyrolysis, the waste tyre will be broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and carbon black, to generate quality fuel with lower emissions, control waste tyre pollution, recover energy from waste and help recycle carbon. The obtained final products can also help our customers to generate huge profits. The following is a profit analysis of DOING 15TPD waste tyre recycling plant:

Profit analysis of DOING waste tyre recycling plant

Profit analysis of DOING waste tyre recycling plant

In a word, waste tyre recycling plant is the best method for waste tyre management. If you are interested in our waste tyre recycling plant, just feel free to send you inquiries. In addition to detailed machine introduction and real projects display, DOING also has a small waste tyre recycling plant in our factory, providing demonstration and raw material testing for our customers specially. Looking forward to cooperating with you.

Prev: Nothing

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications