Waste Oil Solution

Present situation and pollution of waste oil

Waste oil is mainly the polluted or used oil generated from industry and human life. The most typical waste oil is waste engine oil. Waste engine oil is fresh engine oil after some time use become black and sticky by mixing with water or dust or metal powder of the equipment abrasion or other impurities. And waste engine oil is mainly come from vehicles. We know how many and how often we use vehicles in our life, so we could imagine how big is the waste engine oil amount generated per day or per month or per year. Normally, one car one year needs to be maintained for two times. Every time, 4 liters waste engine oil would be changed by fresh engine oil. This way, take in China for example, every year, there would be ten million tons waste engine oil is generated. In many countries, waste engine oil is classified as hazardous waste, which could not be thrown away directly. Once waste engine oil goes into water and soil, it would heavily pollute the water and soil, thus cause serious pollution.

Waste oil

Waste oil

The current dispose methods for waste oil

1. No treatment, directly use waste oil as heating fuel for heating boilers;

2. Used as release agent for building template or water-proof pigmentum, etc;

When waste oil used as release agent for building templates, it would be painted on the building templates before pouring concrete, thus to prevent the concrete stick to the building templates.

Also waste oil could be sprayed on the dusty roads to prevent dust fly everywhere.

3. Simple filtration, then use again;

4. Traditional regeneration, treated by distillation and chemicals, then get clean fuel or base oil for recycle use;

All the above treatment methods could make secondary use for the waste oil. But think it deeply, you could find that all these methods would still cause pollution to the air or soil or water. After a few year study and research, we DOING Company developed a new type and clean regeneration method for treating the waste oil – catalytic distillation.

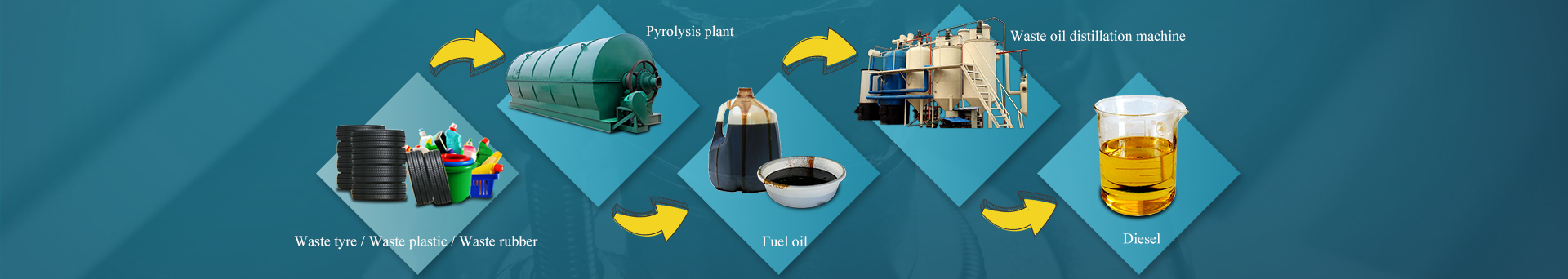

Clean solution for waste oil regeneration – Distillation with catalyst technology

Distillation with catalyst technology is a hybrid design that utilizes the dynamics of simultaneous reaction and separation in a single process unit to achieve a more compact, economical, efficient and optimized process when compared to the traditional multi-unit designs. The new distillation technology could separate different fractions of the waste oil by temperature control. And then use catalysts to crack and absorb the heavy fraction, thus to light oil. In this distillation process, we use catalysts instead of chemicals, which would not generate chemical pollution to the environment.

Distillation with catalyst technology

Distillation with catalyst technology

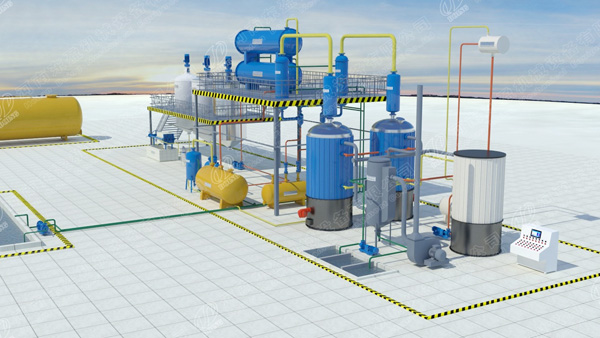

Advantages of the new distillation with catalyst technology

1) Environment protection

This new distillation technology adopts catalysts instead of chemicals to process the waste oil to diesel, thus would not generate chemical pollution to the environment.

2) Low land occupy size

For this new distillation machine, the catalyst tower is directly set on the top of the distillation reactor, thus no need extra space for the catalyst tower, so the land occupy size is much smaller than the traditional design.

3) Easy to operate

For the catalyst design distillation machine, catalysts would be put into the catalyst tower before start the first process, and the catalysts could be kept using for 3 months without changing. Instead of put chemicals every process, the catalyst distillation design could save many labor works and much easier to operate.

4) High benefit

From the distillation process, the final product would be diesel and asphalt, which could be directly sold to the market and get profit immediately.

The application of diesel oil from DOING distillation plant:

Application of diesel fuel oil and asphalt from DOING distillation plant

Application of diesel fuel oil and asphalt from DOING distillation plant

The diesel oil obtained by distillation plant has many important USES in life. For example, it can be used in tractor, ship, truck, and boiler, etc.

So, if you want to dispose of a large amount of waste oil, or if you are looking for a more profitable project, you can buy the waste oil distillation plant made by DOING company. Anything you want to know more about this new distillation plant, our professional project manager is waiting for your consult anytime.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications