Distillation machine profits analysis

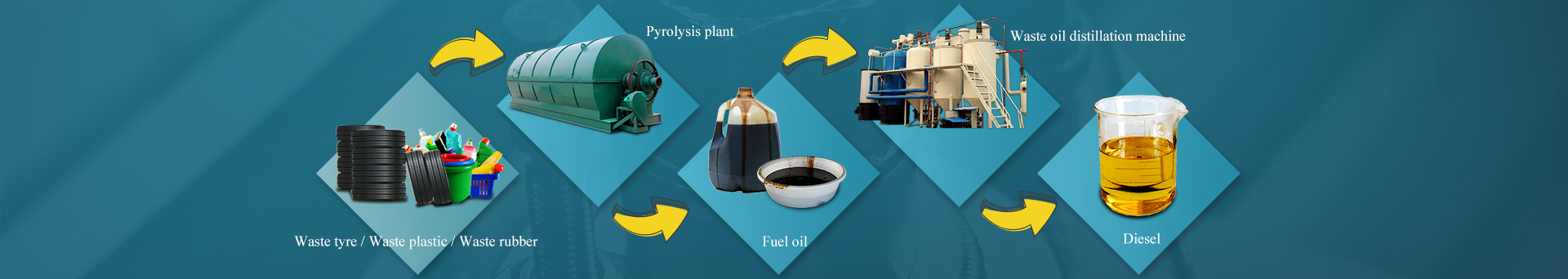

The distillation machine is the process of further refining and refining the pyrolysis oil into diesel oil by using high-temperature distillation and condensation. Can get 80-85% of diesel, 15-20% of asphalt, diesel is mainly used for diesel generators, light fuel, heavy machinery. Asphalt is mainly used for direct paving or for asphalt refinery.

3D distillation machine

In addition, DoingGroup's refining equipment has two alternative systems

Rapid heating system:

The rapid heating system of the refining equipment uses the circulating heating medium and the fuel to heat at the same time, on the one hand, it can save fuel, and on the other hand it can speed up the distillation speed.

Diesel purification system:

The diesel refined from the standard refining system is brownish yellow. If you want to get better color diesel, we can also provide a deep purification system, and finally you can get pale yellow diesel products.

DoingGroup's distillation machine advantages

Plus two alternative systems can get better color, higher purity diesel, has a broad market prospects. What are the advantages of DoingGroup's refining equipment?

1. Double heating system can improve equipment operation efficiency and save fuel.

2. The vertical design of the reactor is more conducive to slagging than the horizontal reactor.

3. The cooling system uses circulating water to cool, with almost no water consumption, which can save costs.

4. The user can customize the small model trial production equipment according to their own needs, so that the funds can be controlled easily.

5. The equipment is simple to operate and requires only two workers, and the labor cost is low.

Distillation machine profits analysis

From the above advantages we can conclude that refining equipment has a huge return on investment. To demonstrate this, we show below the example of a 10-ton refinery that returns a few months of investment in production.

| Waste oil profit analysis(Take 10T machie for example) |

| Operating costs/day |

| Waste oil | 10 tons X 288USD/ton= 2868USD |

| Heating fuel can use any of the following | 1) Coal: 0.4 tons X 64USD/ton = 25USD |

| 2) Fuel: 0.6 tons X 478USD/ton = 287USD | |

| 3) Diesel: 0.5 tons X 765USD/ton = 382USD | |

| 4) Natural gas: 200m3 X 0.36USD/m3=72USD | |

| Power consumption: | 25KW/h X O.16USD X 20h=80h |

| Water consumption: | water is recycled, almost no consumption |

| Workers: | 1-2 people X 16USD = 32USD |

| Profits/day |

| Fuel: | 8 tons X 765USD/ton = 6118USD |

| Asphalt: | 1.5 tons X 175USD/ton = 263USD |

| Profit/day (calculated on fuel diesel) | 18,950 yuan/day, which is equivalent to US$3017. |

The above analysis and calculations show that it is beneficial to purify refined diesel from waste oil or pyrolysis oil. According to the calculation of $3017 a day, the cost of a piece of equipment is $60,000, which means that if you run our equipment, you will be able to recover equipment costs within a month, and in the future it will bring you more revenue!!!

DoingGroup will provide you with technical guidance and solutions for refining tire oil. Welcome to you.

Distillation machine Technical parameter

| Technical parameter of distillation machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications