Waste oil into diesel oil refining machine

Waste oil

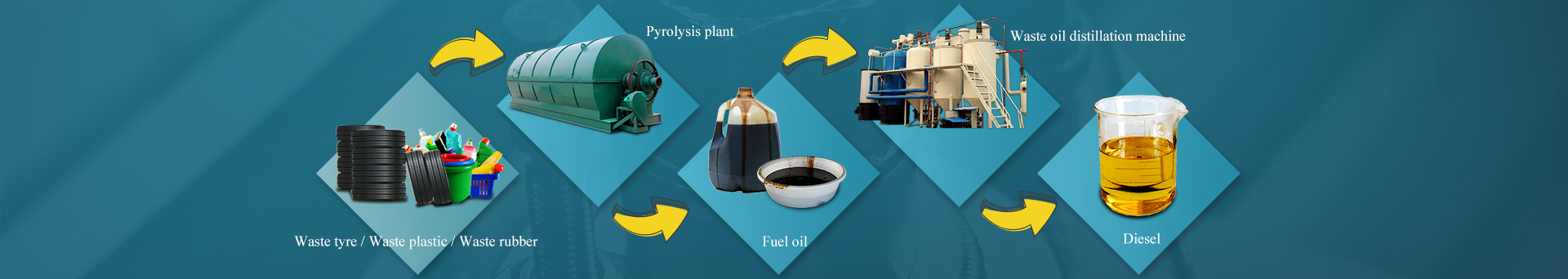

Waste oil into diesel oil refining machine working process

1. Collect used oil.

2. The waste oil after high-temperature distillation.

3. Condensate oil and gas, liquefied oil and gas purified to light oil into the tank.

4. The resulting light oil degreasing, bleaching and further purification.

5. Finally get clean, transparent non-standard diesel.

Advantage of waste oil into diesel oil refining machine

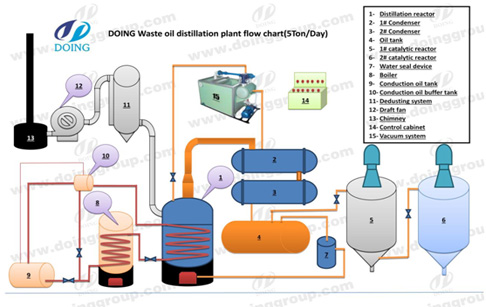

1. Reactor to break the traditional horizontal design, vertical design, easy slagging, improve efficiency.

2. The use of dual heating system, on the one hand, base heating, on the other hand designed a special thermal conductivity system. Save heating time, improve equipment operating efficiency.

3. R & D design and processing integration services, according to customer demand for the design of small-scale pilot production equipment.

Waste oil into diesel oil refining machine Technical parameter

| Technical parameter of waste oil into diesel oil refining machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

After the above steps, the final products of waste oil / lubricant / engine oil are: 85% diesel, 10% asphalt, 5% water and other impurities, of which diesel and asphalt can be used in all aspects of life.

Diesel oil usage

2. Asphalt: Can be used directly for paving, can also be transported to the asphalt plant for further refining.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications