Waste oil to diesel plant

Waste oil to diesel oil plant

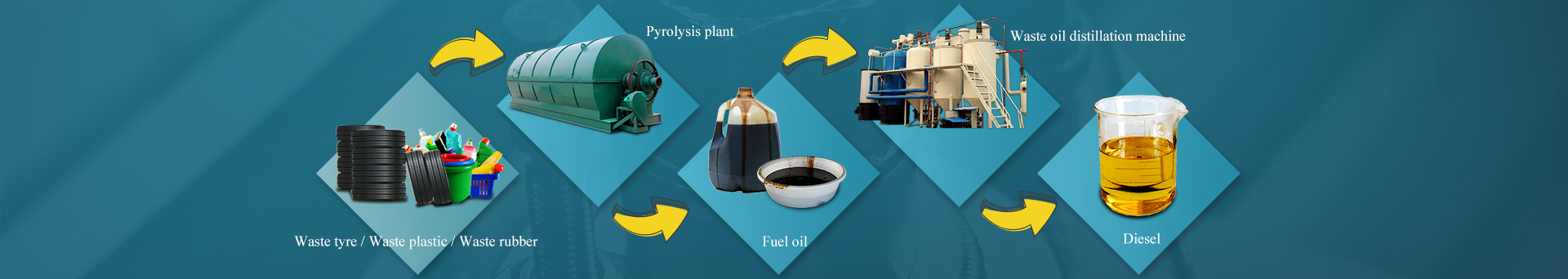

With the deepening of the energy crisis, many people now want to start the project of waste oil to the diesel plant. Maybe it sounds simple, but as a person in the industry, give you a suggests:usually buy the right equipment to determine your future profitability! ! The DoingGroup's refined distillation technology from waste oil to diesel plant can convert waste engine oil, crude oil, and cracked oil into high-quality diesel. If you have a lot of waste oil resources and want to invest in this project, consider DoingGroup as your partner! !

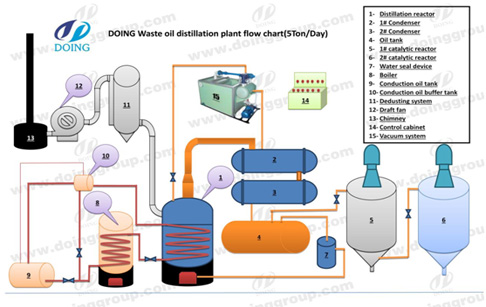

Waste oil to diesel plant working process:

Waste oil to diesel oil working process

1. Pour crude oil, waste oil, pyrolysis oil, used engine oil, etc. into the reactor and heat the reactor.

2. When the temperature reaches a certain height, it will distill out light oil and gas, and some impurities.

3. Light oil and gas are liquefied under high and low pressure and fall into the tank.

4. Desulfurization and degreasing of the obtained diesel oil is a clean and transparent odor-free diesel product.

5. A three-stage dust collector is used to remove dust from the flue gas generated during the combustion process to ensure that the emitted gas is free from pollution.

DoingGroup's unique advantages from waste oil to diesel plant:

DoingGroup's waste oil to diesel plant

1. High oil production rate makes our factory more competitive in the market. The oil production rate can reach 85%-90%. Taking waste oil as an example, if the water content of the waste oil is less than 5%, the oil yield can reach 90%.

2. The operation is simple and the daily maintenance is relatively easy.

3. The factory saves energy. Because combustible gases can heat the reactor.

4. Environmental protection is one of its greatest strengths. Because it does not cause any pollution to the environment. So the factory complies with the environmental protection policy.

5. Quality is an important factor. We have passed CE, IS and SGS certification to ensure its quality.

Our plant is superior in technology and environmental-protection design. In addition, the service of our company is also first-class. You can enjoy the best the customized services and after – sale service if you buy our waste oil and pyrolysis oil refining plant. Contact us now.

Waste oil to diesel plant technical parameter

| Technical parameter of waste oil to diesel plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Through this process we can get 85-90% diesel, 10% bitumen, 5% water and other impurities. Waste oil to diesel plant final products have a wide range of uses in life:

1. Diesel oil: Mainly used for diesel generators, light fuel, heavy machinery.

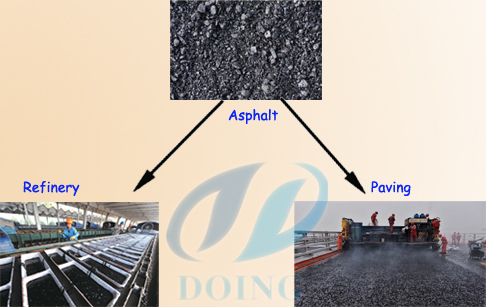

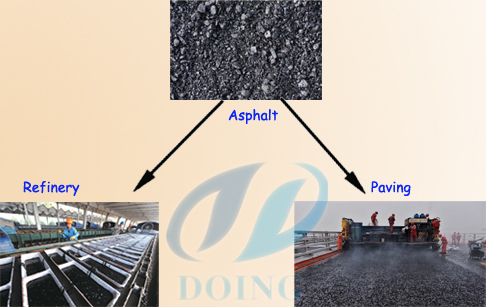

Asphalt usage

2. Asphalt: Mainly used for direct paving, or sent to asphalt refineries.

Diesel oil usage

1. Diesel oil: Mainly used for diesel generators, light fuel, heavy machinery.

Asphalt usage

2. Asphalt: Mainly used for direct paving, or sent to asphalt refineries.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications