How to make diesel from plastic ?

Pyrolysis plastic to diesel plant

Plastic pyrolysis plant pyrolysis waste plastic to plastic oil

First step---plastic pyrolysis plant pyrolysis waste plastic to plastic oil

You know, plastic pyrolysis is a thermo decomposition of plastic polymer, since waste plastic are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross linked or straight chain.During high temperature processing, this long chain( C-50,000 to C-2,00,000) is broken down into smaller chain (C-1 to C-4 & C-5 to C-23). Among which, C5-C23 is oil got from long chain plastic polymer.

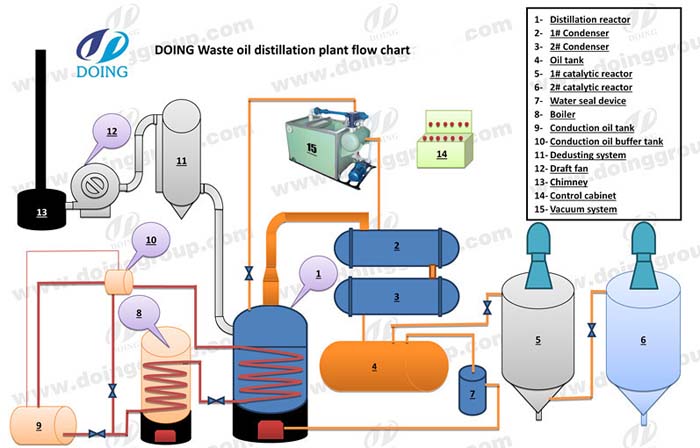

Secone step---Pyrolysis plastic oil to diesel plant pyrolysis plastic to diesel

Pyrolysis plastic oil to diesel plant pyrolysis plastic to diesel

First, pump the waste plasitc oil into reactor by oil pump.

Second, use coal/wood/natural gas/fuel oil/electricity heating the reactor.

Third, after heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get diesel and gasoline separately, through temperature control could separate it and collected into two different oil tanks.

Fourth, some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

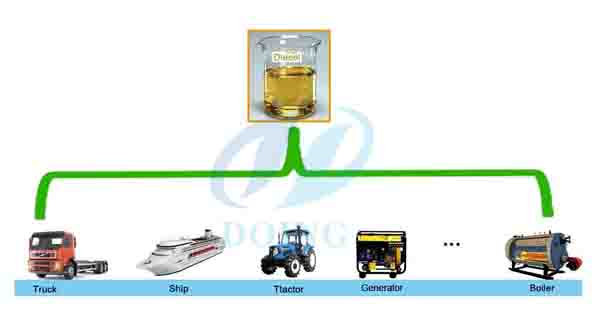

By pyrolysis plastic to diesel fuel plant ,we get diesel from waste plastic oil ,can used for tractors ,trucks,ships and generator

Diesel fuel application