Plastic to diesel process?

Waste plastic pyrolysis plant

As the speed development of plastic industries, the application of plastic products has been becoming wider and wider. The wide application of the plastic products bring many convenience to people’s life, but in the same time, it causes problems. As we all know that plastics are very difficult to decompose in the natural environment, thus more and more plastic waste generate serious environment pollution.

The waste plastic pyrolysis plant adopts pyrolysis technology that pyrolysis plastic to fuel oil and carbon black.

The waste plastic pyrolysis plant adopts pyrolysis technology that pyrolysis plastic to fuel oil and carbon black.

Plastic to diesel process plant

2. It takes approximately 1 1/2 hours to get the system to 300 Degrees Celciuss.

3. From 300 to 350 degrees you get a multifuel, from temperatures over 350 degrees the pertrol/nafta is split off and a light diesel gas oil is left in the primary condenser.

4.The system can take condensed pure plastic loads of up to 100kg, experience has shown that when you insert bags and pieces of plastic you get a lower KG density load in the system. This will result in you running the system for 3 to 4 times per day to get over 100 litres of fuel per day.

5.The PLASTIFUEL 100 produce more than 100 litres per day.

6.Use Gas, Wood, Charcoal and excess gas from the Plastifuel for heating the system.

7. No power equired.

8.The diesel is basically a Light Diesel Gas Oil and the Petrol is a Petrol/Nafta type fuel.

We suggest to use plastic to diesel process plant to convert plastics to these fuels foe own use in older basic engines or as a burner fuel.

Plastic to diesel process?

Plastic to diesel process waste plastic oil to diesel

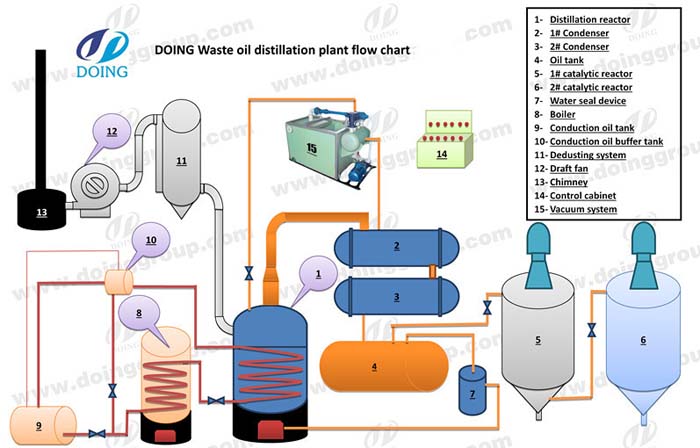

Secondly, after 3 hours, the sediment of the raw material precipitation tank will be discharged, and then the crude oil, which has finished the precipitation, will be pulled into distillation tower through the oil pipe.

Thirdly, start to distill the oil with high temperature, and use fuel oil to heat distillation reactor; at this time, the raw material will be heated circularly between the oil heating furnace and distillation reactor; when it reaches the related temperature, the oil gas of each reactor will enter the heat exchange system and condenser system in order through the distillation tower. The final products including gasoline and diesel will be stored into oil tank respectively.

After processed by the waste plastic to diesel process plant, the various kinds of waste oil can be turned into diesel ,the diesel can be used for tractors, trucks, ships and diesel oil generators etc.