How to build a simple vacuum distillation process equipment?

Vacuum distillation process equipment

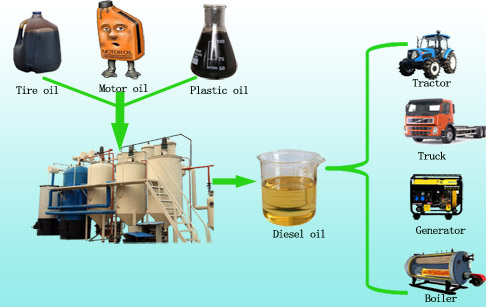

A. How to collect raw material? For a simple vacuum distillation process equipment, the raw materials could be crude tire/plastic pyrolysis oil or waste engine oil, used motor oil, etc. So you will collect the raw materials by yourself or directly buy from the collectors?

B. How much do you need to pay for the raw materials?

Like in China, if from the collectors, we need to pay 150-200 dollars for one ton waste engine oil, , which is relatively expensive. But in some countries, you could collect it for free. And even in some countries, if you can dispose the waste oil, the government will give you some supports.

C. How to deal with the final products? Sell them or used for yourself?

D. If you want to sell out the products to get money, how much can you sell? How about the profit?

Note: Instructions for the final products

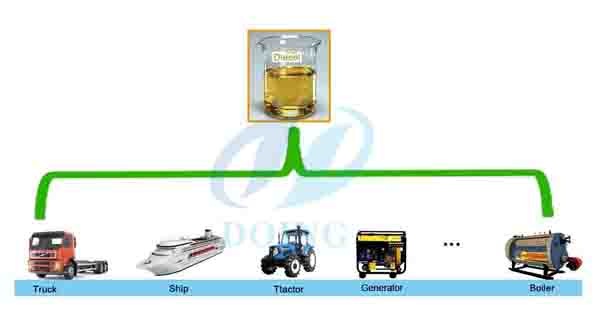

Diesel fuel oil application

This oil product is a kind of clean fuel oil, which is very similar like diesel. To a great extent that it could be used instead of normal diesel in some heavy engines, diesel burners or generators. Or if can be used as clean fuel oil for industrial heating used in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, boiler used factory, etc.

--- Asphalt

Except the diesel-like fuel produced from the vacuum distillation process equipment, you could also get the by product, the very heavy oil sludge, which could be directly used as asphalt for construction or paving.

Step II. Profit analysis

During the first step project investigation, it needs you to make a lot of market research, and you would get a lot of the numbers about costs or returns. This way, you could calculate out of your own profit to do this project.

Step III. Prepare the land

Prepare the land

Step IV. Buy a vacuum distillation process equipment

When you’re planning to buy a machine, the quality and performance will be the most important part. For our vacuum distillation process equipment, the main advantages are:

1) High quality

For the oil pressing machines, since there is oil gas produced, the machine should be produced strictly according to the pressure vessel standard. And all the sealing tools or materials we use are according to international standard.

2) Fast heating

Normally the distillation process needs a long heating process, but with our unique design with heat transfer oil heating, we could save half of the time for the distillation process. And the heat transfer oil could be recycled used, which could save a lot of time and energy for you.

3) Automatic slagging

As you know that the residues after diesel come out is very heavy oil sludge, like asphalt. When it’s hot, it’s liquid; when it’s cold, it become solid, which is very difficult for manual discharging. For our machine, we have the vertical reactor design, which could make automatic slagging for the asphalt.

C. Environmental protection measures

There are mainly 4 possible sources of pollution from the vacuum distillation process equipment, and they are respectively Water Pollution, Air Pollution, Bad Smell and Noise Pollution.

No water pollution:

The water used in our distillation system is all for recycle use, no need to discharge and change.

No bad smell and air pollution:

The emissions from our system before discharged should be cleaned by our odor removal and dedusting system, after cleaning it has no pollution materials, just like water steam.

No noise pollution:

The noisiest part of our machine is the drat fan. Its noise is less than 50db.

D. Supplier experience

Vacuum distillation process equipment in Mexico

Vacuum distillation process equipment installed in Colombia

We DOING Company as a leading company for manufacturing and supplying waste recycling machinery has specialized in this field for almost 11 years, 4 years for domestic market, 7 years for international trade.

By now, we have installed hundreds of machines in more than 35 countries all over the world:

Africa: South Africa, Egypt, Nigeria, Sudan, Ethiopia, Congo, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey, Estonia, Georgia;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan, UAE, Palestine;

America: USA, Mexico, Ecuador, Haiti, Guatemala, Aruba, Panama, Jamaica, Colombia.

Oceania: Australia, etc.

And we have very professional engineers which can be sent to your site for machine installation, commissioning and training your workers.