What factors need to be considered when building a waste oil refinery plant?

Industry News / Chat on line / Give me a price / May 11, 2023

The waste oil recycling and regeneration technologies are becoming more and more popular all over the world, and the waste oil to diesel refinery technology is one of them. The construction of a waste oil refinery plant is an important project, and the following factors need to be considered:

1. Collect enough waste oils

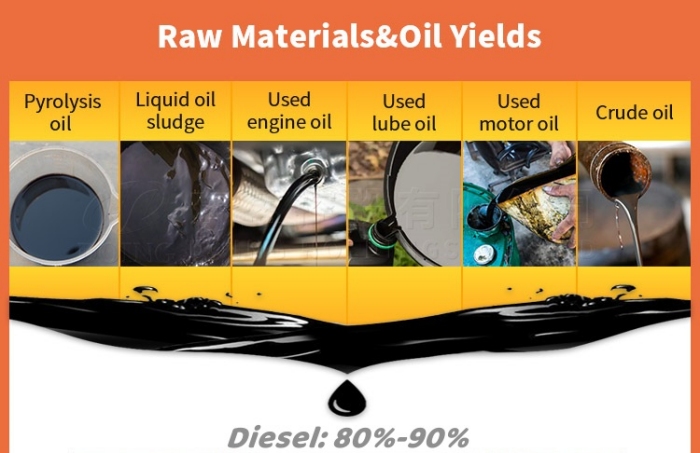

The material resource is important, because if you want to make profit, you’d better run the machine constantly, so a stable material supplier is very important. You could find the supplier who provides the waste oil specially or you could cooperate with local factories which produce the waste oils like used engine oil, waste motor oil, old lube oil, tire plastic pyrolysis oil, etc. every day, then you need to calculate how much waste oil you could collect per day, and we could recommend the suitable processing capacity machine for you according to your material amount.

Various raw materials for waste oil refinery plant

Various raw materials for waste oil refinery plant

2. Look for the final product market

You will get diesel and asphalt from the waste oil refinery plant, the diesel could be used for the big trucks, trailers, cranes, generators and boiler factories etc. The asphalt is a kind of common asphalt, and could be used to pave the road and repair the roof. You need to find the buyer at local or export these final products abroad.

3.Prepare the suitable installation land

You need to find a suitable land, usually it’s empty industrial land or a ready-made factory in the industry park. And the land size mainly depends on what scale of this project you want to build and you also need to consider the material store and final product stock. For example, for a big scale waste oil refinery plant with a capacity of 10-15TPD, it takes about 400 to 500 square meters. If you have your own land which could be used to install this kind of project, that’s the best.

On-site installation picture of DOING waste oil refinery plant

On-site installation picture of DOING waste oil refinery plant

4. Prepare the fund

This is the most important thing, but how much of the fund you need to prepare also depends on your local market, and the waste oil refinery machine cost also depends on your project scale. We have professional sales and engineering teams to give you more professional advice and help you plan the waste oil refinery plant well.

5. Purchase and install the waste oil refinery machine

High-quality waste oil refinery machine is the basis for the smooth operation of waste oil refineries, so there are many aspects to consider when selecting equipment. For example, equipment should have high efficiency, stability, safety and other characteristics.

Project cases of DOING waste oil refinery plant

Project cases of DOING waste oil refinery plant

Henan DOING Company has been engaged in the refinery plant R&D for over 13 years and has mature technology and rich practical experience in many countries. And after you place the order, we usually can deliver the machine in 30 working days, and then we will send the engineer to your site to help you install the waste oil refinery machine.

If you want to get more guidance and information about building waste oil refinery plants from us, please feel free to contact us.