Continuous plastic pyrolysis plant

Continuous plastic pyrolysis plant

We, Henan Doing Environmental Protection Technology Co., Ltd.is a world leading manufacturer and supplier specialized in waste tire /plastic/rubber pyrolysis plant. Our professional engineer team has developed highly efficient fully continuous plastic pyrolysis plant.

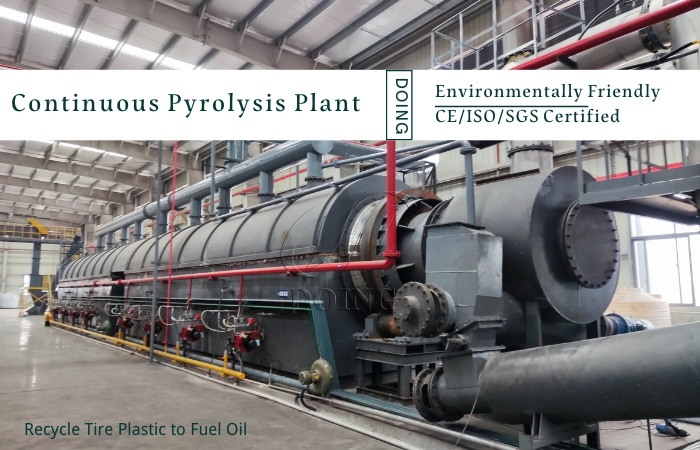

Continuous plastic pyrolysis plant picture

Continuous plastic pyrolysis plant picture

Our continuous plastic pyrolysis plant can continuously processes various plastic into crude oil(plastic fuel oil), carbon black and combustile gas without stopping. All the continuous plastic to oil pyrolysis plants are controlled by intelligent PLC(programmable logic controller), so it is very easy to operate and our customers can save much time and labor.

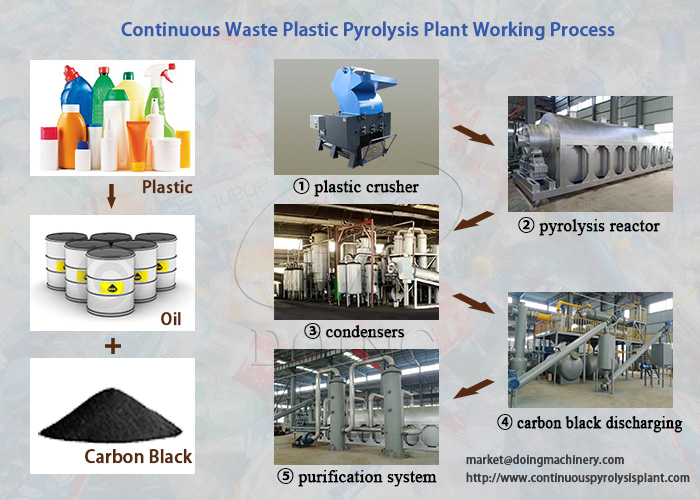

Here is a process picture for you to understand:

Continuous plastic to oil pyrolysis plant working process

Continuous plastic to oil pyrolysis plant working process

All available plastic(except PVC and PET plastic) can be shredded by plastic crusher, and then plastic granules can be fed directly into continuous plastic pyrolysis plant through the feeding door. Our feeding door has screw inside, so it can help you easily convey the plastic granules into our reactor No 1, then all the waste plastic can be fully decomposed under the high temperature through reactor No 1 to reactor No 2. pyrolysis reacyor until all the plastic fully pyrolysed, then all the carbon black powder will be discharged automatically to the carbon black tank.

All the available oil gas will be cooled by circulation water of our multiple-stage cooling system, and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous plastic pyrolysis plant, the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and water resource. In this way, our continuous plastic pyrolysis plant can minimize your cost and maximize your profits.

Through our continuous plastic pyrolysis plant, you will convert waste plastic into fuel oil, carbon black and syn-gas easily and automatically. If you need more information and help, welcome to contact us at any time. DOING fully continuous plastic pyrolysis plant is also equipped with environmental protection system, which can meet the EIA and environmental standard.

Continuous plastic pyrolysis plant technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Continuous plastic pyrolysis plant application

Fully continuous pyrolysis plant final products and applications

Fully continuous pyrolysis plant final products and applications

As we can see from the pictures, the fuel oil and by-products of continuous plastic pyrolysis plant has wide applications. The fuel oil can be used as a great heating fuel for heavy industries, various boilers and furnaces. You can also refine the plastic pyrolysis oil into diesel fuel by DOING pyrolysis oil distillation plant. And for the carbon black, you can use it for briquette or making new products. And the syn-gas will be used for heating continuous pyrolysis reactor to save operation cost.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications