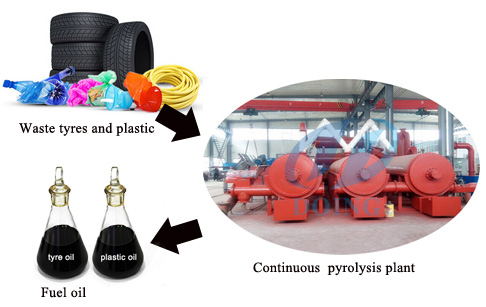

Continuous scrap tire pyrolysis production line

Continuous scrap tire pyrolysis production line feature

1. Reactor with auto welding to guarantee the quality of welding seam and avoid cracking

2. Professional heating treatment and x-ray detection chamber for welding seam.

3. Vacuum system to prevent oil gas be back to reactor causing accident.

4. with temperature meter, pressure meter and safety valve.

Environment friendly:

1. Dedusting system to prevent gas and dust from coal burning

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Well sealing on every junction parts to prevent gas leak, no smelly

Longer life:

1.use Q245R special steel plate ,thickness 16mm. welding seam with auto welding and will get heating treatment and x-ray detection to extend the life of reactor to the most extend.

2. The life will be 6-8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel

Continuous scrap tire pyrolysis production line

Safety:1. Reactor with auto welding to guarantee the quality of welding seam and avoid cracking

2. Professional heating treatment and x-ray detection chamber for welding seam.

3. Vacuum system to prevent oil gas be back to reactor causing accident.

4. with temperature meter, pressure meter and safety valve.

Environment friendly:

1. Dedusting system to prevent gas and dust from coal burning

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Well sealing on every junction parts to prevent gas leak, no smelly

Longer life:

1.use Q245R special steel plate ,thickness 16mm. welding seam with auto welding and will get heating treatment and x-ray detection to extend the life of reactor to the most extend.

2. The life will be 6-8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel

Continuous scrap tire pyrolysis production line technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

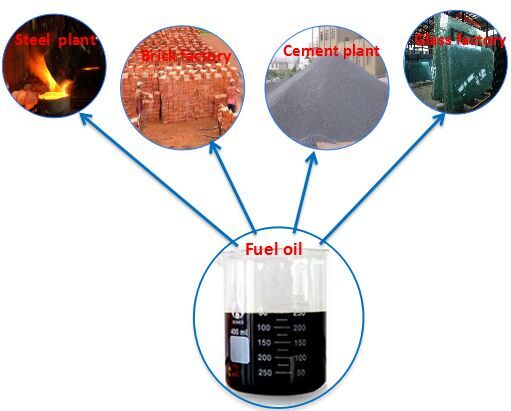

Final product application of continuous scrap tire pyrolysis production line

Final product application of continuous scrap tire pyrolysis production line

Waste tire is a big problem for all countries, which not only cause pollution but also easily proliferate diseases thus endanger people’s life. Our continuous scrap tire pyrolysis production line is a green technology for waste tires recycling.Waste tire can dispose waste tyres environmental friendly and bring considerable profit.

After processed by our continuous scrap tire pyrolysis production line, you can get fuel oil. Fuel oil is a very good heating fuel. It has wide market in different countries.

Till now, our continuous scrap tire pyrolysis production line has been exported to more than 30 countries, such as Italy, Romania, Turkey, Bangladesh, Nigeria, Malaysia, Mexico, Columbia, etc.

If there are many waste tires thrown in your country, it will be a good chance for you to start the project of continuous scrap tire pyrolysis production line.