Automatic and continuous waste plastic pyrolysis plant

Automatic and continuous waste plastic pyrolysis plant

Automatic and continuous waste plastic pyrolysis plant

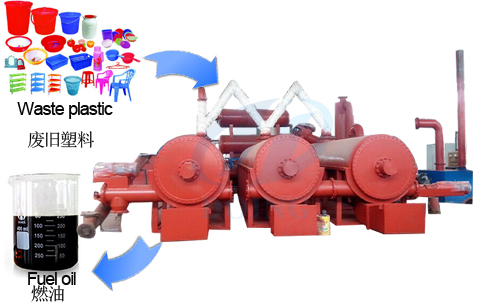

Waste plastic is a big problem for all countries, which not only cause pollution but also easily proliferate diseases thus endanger people’s life. Our automatic and continuous waste plastic pyrolysis plant is a green technology for waste plastic recycling.

Automatic and continuous waste plastic pyrolysis plant

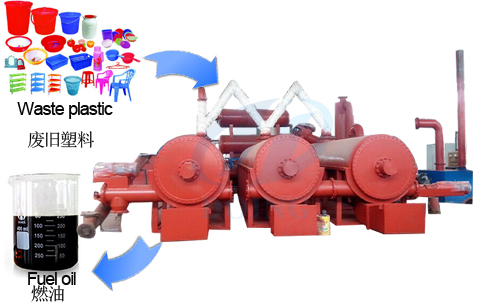

Waste plastic is a big problem for all countries, which not only cause pollution but also easily proliferate diseases thus endanger people’s life. Our automatic and continuous waste plastic pyrolysis plant is a green technology for waste plastic recycling.

Automatic and continuous waste plastic pyrolysis plant can dispose waste plastics environmental friendly and bring considerable profit.

After processed by our automatic and continuous waste plastic pyrolysis plant, you can get fuel oil. Fuel oil is a very good heating fuel. It has wide market in different countries.

Till now, our automatic and continuous waste plastic pyrolysis plant has been exported to more than 30 countries, such as Italy, Romania, Turkey, Bangladesh, Nigeria, Malaysia, Mexico, Columbia, etc.

If there are many waste plastic thrown in your country, it will be a good chance for you to start the project of automatic and continuous waste plastic pyrolysis plant

After processed by our automatic and continuous waste plastic pyrolysis plant, you can get fuel oil. Fuel oil is a very good heating fuel. It has wide market in different countries.

Till now, our automatic and continuous waste plastic pyrolysis plant has been exported to more than 30 countries, such as Italy, Romania, Turkey, Bangladesh, Nigeria, Malaysia, Mexico, Columbia, etc.

If there are many waste plastic thrown in your country, it will be a good chance for you to start the project of automatic and continuous waste plastic pyrolysis plant

Automatic and continuous waste plastic pyrolysis plant technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Automatic and continuous waste plastic pyrolysis plant application

Carbon black: Carbon black from this Automatic and continuous waste plastic pyrolysis plant can be used to brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. You can take carbon black for deep processing.

Automatic and continuous waste plastic pyrolysis plant

Carbon black: Carbon black from this Automatic and continuous waste plastic pyrolysis plant can be used to brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. You can take carbon black for deep processing.