Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant introduction

Continuous waste plastic pyrolysis plant

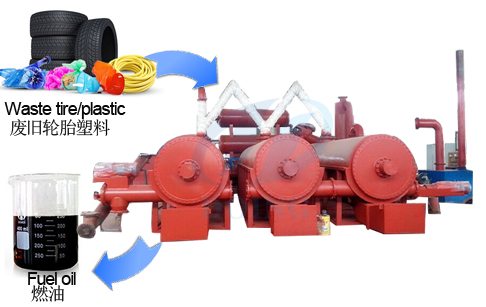

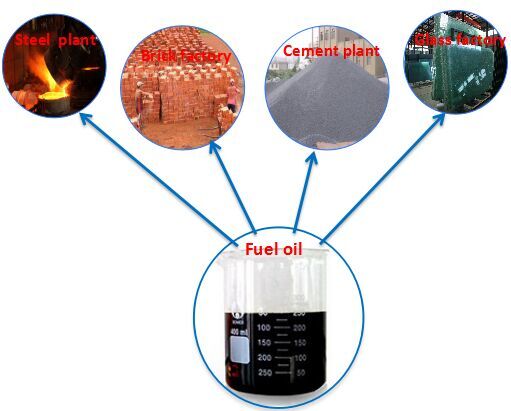

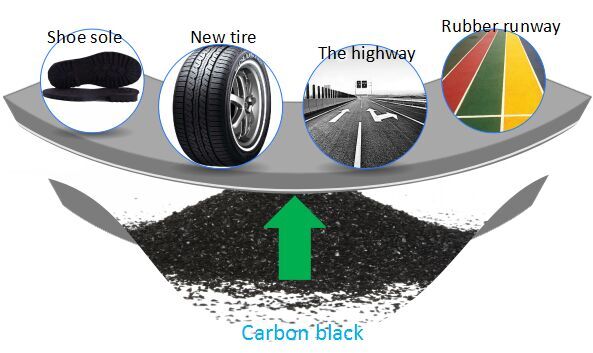

Our continuous waste plastic pyrolysis plant will process waste plastics with pyrolysis technology. After processing, the final products will be fuel oil and carbon black. Fuel oil is a good heating fuel which can be used in many industries for heating purpose. Carbon black and be further processed into pellet or powder.

Till now, our continuous waste plastic pyrolysis plant has be exported to more than 30 countires, such as Egypt, Malaysia, Mexico, Italy, Romania, Ecuador, Haiti, Thailand etc.

If your country also faces with plastic pollution, welcome to contact us and get more information about our continuous waste plastic pyrolysis plant.

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

1.In the waste plastic continuous pyrolysis process, the waste plastic will firstly be put into the reactor.

2.Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3.Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

4.Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically.

Continuous waste plastic pyrolysis plant

Plastic is widely used in people’s daily life in all countries. It brings people convenience but also causes pollution. Currently, waste plastics are always be disposed by landfill, burning and recycling. However, most of the disposal will cause secondary pollution. The appearance of continuous waste plastic pyrolysis plant produced by Doing Group can not only solve the plastic pollution but also bring huge profit.

Our continuous waste plastic pyrolysis plant will process waste plastics with pyrolysis technology. After processing, the final products will be fuel oil and carbon black. Fuel oil is a good heating fuel which can be used in many industries for heating purpose. Carbon black and be further processed into pellet or powder.

Till now, our continuous waste plastic pyrolysis plant has be exported to more than 30 countires, such as Egypt, Malaysia, Mexico, Italy, Romania, Ecuador, Haiti, Thailand etc.

If your country also faces with plastic pollution, welcome to contact us and get more information about our continuous waste plastic pyrolysis plant.

Continuous waste plastic pyrolysis plant

2.Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3.Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

4.Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically.

Technical data of continuous waste plastic pyrolysis plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

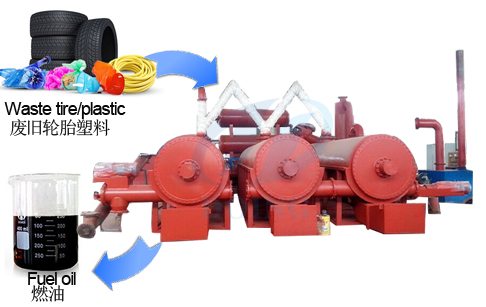

Continuous waste plastic pyrolysis plant final product application

Fuel oil from continuous waste plastic pyrolysis plant

B.glass factory

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

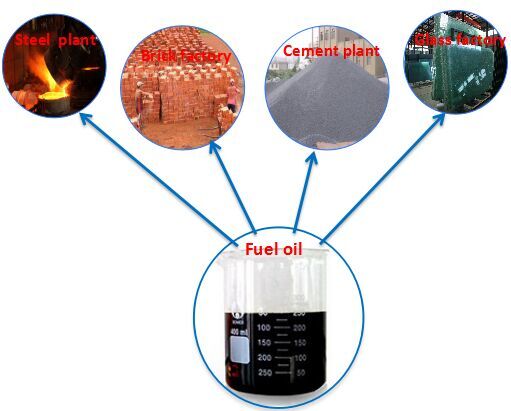

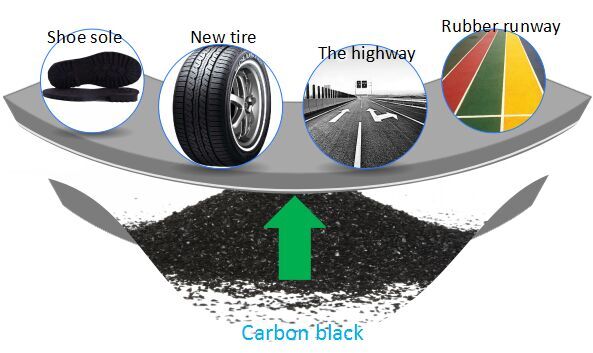

Carbon black from continuous waste plastic pyrolysis plant

A.electric cable jacketing

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare partsG.heat isolation

H.black colorant in rubber materials

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare partsG.heat isolation

H.black colorant in rubber materials

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications