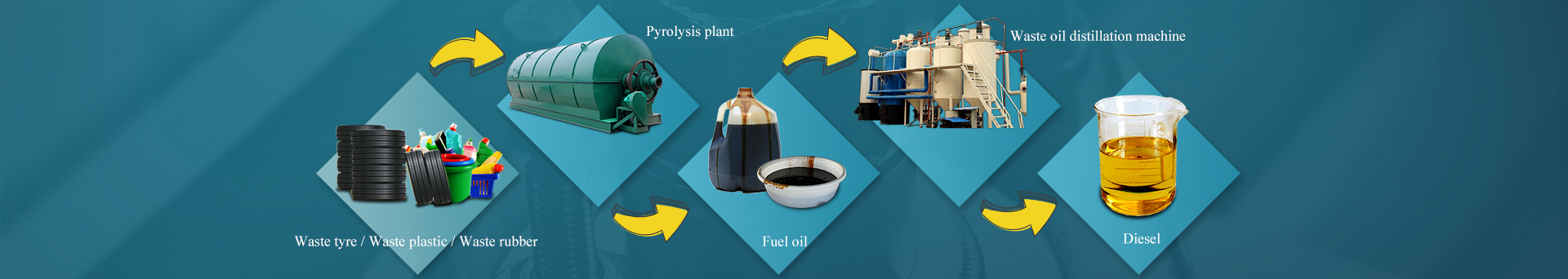

Converting commercial plastic to oil refining plant

| Technical parameter of converting commercial plastic to oil refining plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

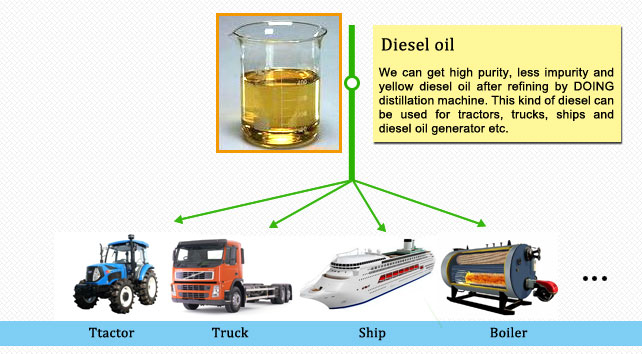

Diesel application of converting commercial plastic to oil refining plant

Advantage of our converting commercial plastic to oil refining plant:

Safety is the most important factor in the whole process. We had successfully researched some safety devices which ensure the Converting commercial plastic to oil refining plant can work safely. Such as, the safety valves, alarming device and the pressure gauge etc.

Prev: Used plastic to diesel oil distillation plant

Next: Nothing

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications