Used plastic to diesel oil distillation plant

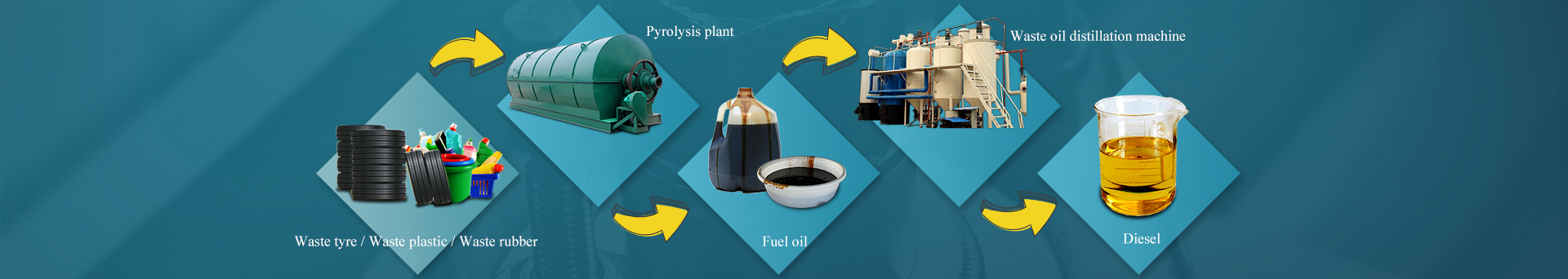

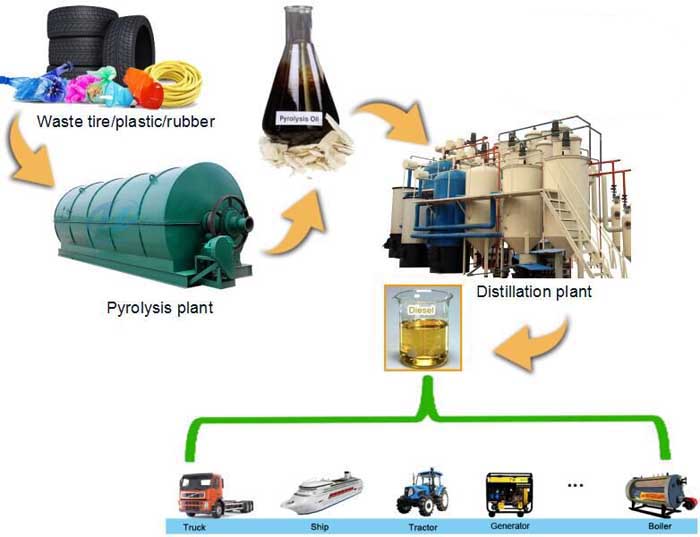

Waste tire/plastic

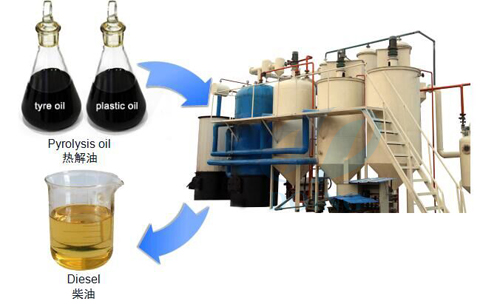

Distillation is the chemical engineering processes and other facilities used in oil refineries to distills the incoming crude oil, pyrolysis oil and waste oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc.

Waste plastic oil to diesel oil machine

Waste plastic oil to diesel oil machine

Used plastic to diesel oil distillation plant

Used plastic to diesel oil distillation plant can treat a variety of waste plastic oil and get high quality diesel and small amount of gasoline through vacuum distillation. After pretreatment, waste oil pumped into the distillation kettle, heating to working temperature, and then we can get the base oil, gasoline and diesel we required.

Used plastic to diesel oil distillation plant

Waste plastic pyrolysis plant of Doing can convert waste plastic to oil and carbon black .The wast plastic oil to diesel oil machine can refine waste plastic oil to diesel very efficiently, and at the moment it is the most energy-saving refinery equipment in the market.

Used plastic to diesel oil distillation plant advantage 1) The plant is certified by CE, SGS and ISO.

2) Latest double vertical tubular condensers, 56 cooling pipes in each condenser, more cooling area, more effective cooling effect, higher oil yield.

3) Equipped with safety valves, auto alarming system, anti-explosion valve, which will guarantee 100% safety.

4) Flue tube condenser, cool down the exhaust gas from the burner, protect draft fan and improve dedusting effects.

5) Adopts Three-layer dedusting system to cleanse the exhaust gas to reach European pollution control standards.

6) Automatic submerged welding technology, ultrasonic nondestructive testing,guarantee the equipment quality.

7) Oil pump feeding and discharging, save much manpower.

Configuration of used plastic oil to diesel oil machine:

Used plastic oil to diesel oil machine installl in Colombia

2. Heating way: wood, coal, crude oil, gas

3. Dust Removing System: water removing

4. Condenser: vertical condensers (water cooling function, improve the oil quality)

5.Safety device: Vacuum system

There advantage of DOING Waste plastic oil to diesel oil machine:

1. There are four reactors for theWaste plastic oil to diesel oil machine. We heat the reactor indirectly by using the Boiler heating system to lengthen the life span of reactor.

2. OurWaste plastic oil to diesel oil machine operates in the vacuum environment to promote the rate of the oil yield and quality of oil.

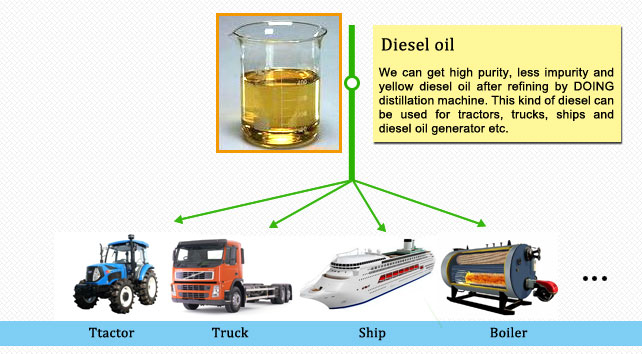

3. There three steps to purify the oil to convert plastic oil to diesel that can be used to the tractors, trucks and diesel generator etc.

| Technical parameter of used plastic to diesel oil distillation | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel from used plastic oil to diesel oil machine can be used for tractors, trucks, ships and diesel oil generators etc. below is the different waste oil with its oil rate.

| Oil yield of different material of plastic to diesel oil distillation | ||

| No. | Name | Oil yield |

| 1 | Waste tire oil | 85%-90% |

| 2 | Waste plastic oil | 95% |

| 3 | Waste engine oil | 85%-90% |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications