8 sets of 15 ton plastic to oil pyrolysis machines installed in China

Congratulation. At the end of August 2023, a large-scale plastic to oil pyrolysis project manufactured and constructed by Doing Company was successfully installed in Henan provoince of China! The plastic pyrolysis machine consists of 8 sets of 15 tons/day plastic to oil pyrolysis machine and has the advantages of intelligent, integrated and efficient large-scale equipment.

Plastic to oil pyrolysis machine installed in China

Plastic to oil pyrolysis machine installed in China

This China customer mainly makes plastic granules, and some scraps will be produced after plastic granulation. We will consider making full use of this part of waste resources and expanding waste plastic recycling to fuel oil business, and creating an environmentally friendly industry that combines plastic granulation and plastic pyrolysis. When customers inspect plastic to oil pyrolysis machines, they are very concerned about the materials, workmanship and service life of plastic to oil pyrolysis machines, and the strength and scale of the equipment manufacturer's fabrication factory.

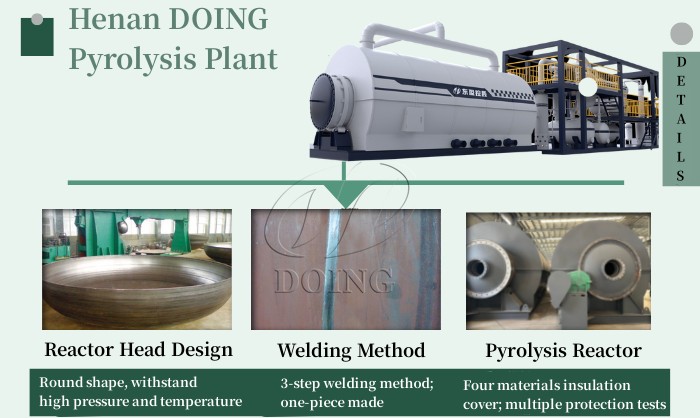

In order to facilitate customers to have a close understanding of the overall quality and equipment operation of the plastic to oil pyrolysis machine, DOING sales manager invited customers to come to the Jiaozuo factory for factory inspection. The main furnace of DOING plastic to oil pyrolysis machine for sale is made of 16mm thick steel plate made specifically for Q245R/Q345R boilers. The ellipsoidal head of the pyrolysis machine is smoothly welded to the furnace body and formed in one piece, with stronger pressure resistance and the highest safety factor. In addition, the thickness and material of the main furnace can be customized, such as: thickness 16mm/18mm/20mm, material Q245R/Q345R/304 stainless steel/316 stainless steel. The customer was very satisfied with this and began to communicate with us about the details of the equipment configuration.

Advantages of DOING plastic to oil pyrolysis machine

Advantages of DOING plastic to oil pyrolysis machine

Providing customers with reasonable solutions, reducing costs and increasing profits has always been our goal. Based on its planned annual processing capacity of 40,000 tons, Doing's engineering team built 8 sets of 15 tons/day plastic to oil pyrolysis machine processing solutions. Reasonable plastic recycling pyrolysis production line design can greatly reduce production costs. The customer expressed that he was very satisfied with the solution. In the end, a purchase contract for 8 sets of 15 tons/day plastic to oil pyrolysis machine was signed at the end of March, 2023 and we successfully reached cooperation.

After the 8 sets of 15TPD waste plastics pyrolysis machines are put into operation, it is expected to process 120 tons of waste plastics a day, achieving considerable economic benefits while reducing and harmlessly treating waste plastics. The following is a picture of the equipment installation site of a regular plastic to oil pyrolysis machine in Henan, China:

Plastic to oil pyrolysis plant project installed in China

Plastic to oil pyrolysis plant project installed in China

According to the acceptance tests, Doing's pyrolysis machines meet environmental requirements for high-standard equipment, and many customers also expressed their satisfaction with the program configuration and equipment design. If you are interested in waste tire/plastic to fuel recycling pyrolysis business, please feel free to get in touch with us for professional solutions.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications