Waste tyre pyrolysis plant project report

First,the background and significance of the waste tyre pyrolysis plant project report

Waste tires

At present, the total amount of tires in the world has already exceeded 100 million tons. China’s tires are also nearly 10 million tons and the annual growth rate of 13% is rapidly increasing. The total amount of used tires will also increase sharply. The contradiction between environment and development will become more and more prominent. The management of used tires has become an urgent task. The treatment of used tires and not polluting the environment is receiving increasing attention.

The easiest way to dispose of waste tires is to make recycled rubber powder and refinery. The production of recycled rubber powder restricts the further development of this project due to its unfavorable reasons such as high production cost, narrow sales channels, and long service life of the production of plastic track. Waste tire pyrolysis plant is attracting the attention of the world because of its good sales, fast turnover of liquidity and high profits. For example, the average domestic recycling price of used tires is 800-1000 RMB/ton, and the oil yield of used tires is 40-45%. In addition, the production costs such as fuel, workers' wages, and water charges can still obtain certain profits.

Process for producing fuel oil in a decomposition tank developed by Mitsubishi Heavy Industries of Japan

The waste tire is crushed into a certain size and dried. The hopper is sent to a melting tank (300-350 degrees Celsius) to be melted and sent to a decomposition tank of 400-500 degrees Celsius for slow decomposition. Each tank is heated by hot air. This oil has a low viscosity and a high freezing point below zero degrees Celsius, but the ignition point is very low. It is a good quality fuel oil. It is best to remove the low ignition point. The non-condensable gaseous compound can be used as a fuel after passing out hydrogen chloride through the absorption tower. A portion of the recovered oil and gas can be used as an energy source for hot air heating in each tank. The waste tire fluidized bed developed by the University of Hamburg in Germany is thermally decomposed into a fuel oil reactor. The waste tires flow out of the hopper and are transported by a screw feeder into the electrothermal reactor where the fluidized layer is about 20M deep. 50L of liquefied heating pyrolysis gas is required per hour. Dedusting in the electric precipitator and partially liquefying the uncondensed gas in the deep cooler can be returned to the reactor as a liquefied medium.

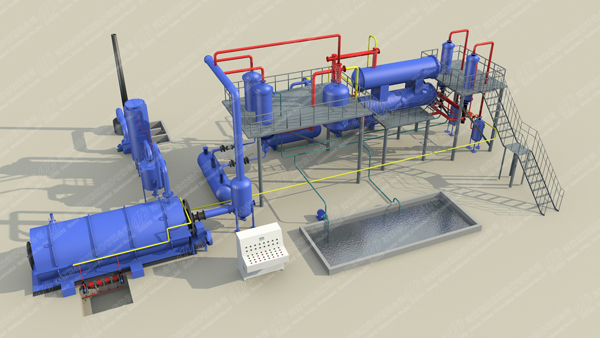

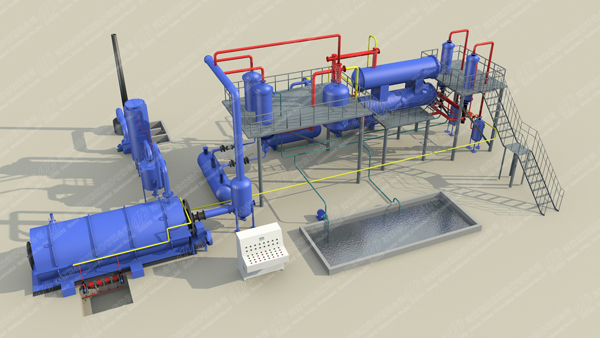

DOING waste tire pyrolysis plant

The fuel chemist Bandit Taghiai of the University of Kentucky in the United States invented the use of zeolite molecular sieves as a catalyst to mix various plastics into a sand bath and then pour this material into a reactor to break it into high quality fuel oil. method. The representative waste tire pyrolysis plant in the whole process can meet the domestic environmental protection requirements in the whole process, but it cannot be promoted because of the high investment amount and low oil yield. The waste tire pyrolysis plant currently used in mainland China mainly adopts the horizontal reaction kettle waste tire pyrolysis plant process as follows:

DOING waste tire pyrolysis plant working process

Second, the latest series of waste tire pyrolysis plant several major features

Take DY-10T as an example for the waste tyre pyrolysis plant project report

1. Each set of waste tire pyrolysis plant consists of ten parts:

DOING waste tire pyrolysis plant main parts

1.1. Raw material pretreatment device

1.2. Rapid feeding device

1.3. Integrated rotary cracker

1.4. Automatic safety and environmental protection slag system

1.5. Oil vapor cyclone dust removal device

1.6. Rapid condensing system

1.7. Exhaust gas purification and recovery combustion system

1.8. Heat source supply system

1.9. Heat source environmental dust removal system

1.10. Central electronic control system

2, the first manufactirer in domestic:

2.1 In the design of the cracking processor of the key equipment for waste tire pyrolysis plant, it has completely overcome the unfavorable factors such as local uneven heating and uneven fracture at the bottom of the vertical flat-bottom cracking processor, low output and short service life. The host adopts a horizontal 360-degree rotating structure of 0.4 rpm. /Minute.

2.2 Waste tire pyrolysis plant has a fast and practical feeding and slagging system.

2.3 Efficient gas heating system. In the process of refining the waste tire pyrolysis plant, when the heated gas reaches 150 degrees Celsius, a large amount of gas which cannot be liquefied at normal temperature and normal pressure, methane to butane, is generated.

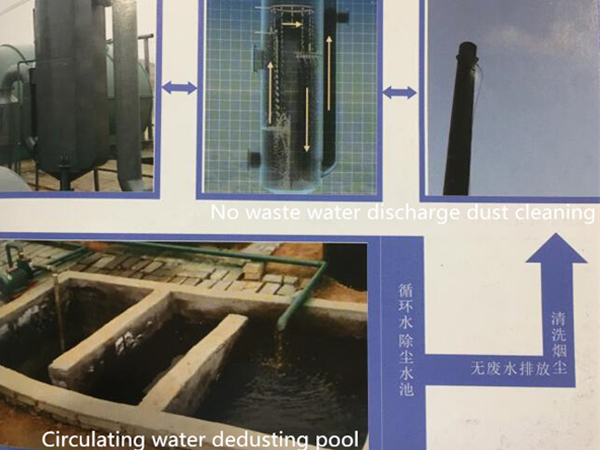

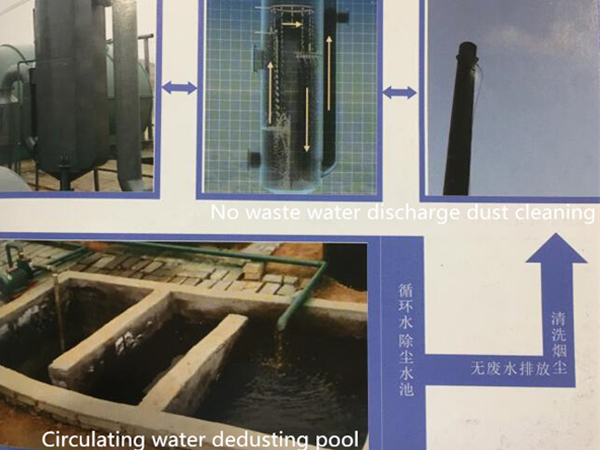

2.4 Flue dust removal system. The waste tire pyrolysis plant is equipped with a water impact type cyclone dust chamber with a dust removal efficiency of over 95%.

3. The company promises:

The various waste tire pyrolysis plant sold by DOING Company has a perfect after-sales service warranty period, which completely solves the worries of customers.

Third, the product and raw materials market

With the rapid development of the world economy, the momentum of oil shortage is increasing. Since the 1990s, energy has become a major factor restricting the economic development of various countries. It has been proved that the oil on the global land will be mined after 15 years and the search for new energy has become the concern of all countries in the world. The problem. China's vast population is vast With the rapid development of the market economy, the demand for vehicles and machinery is increasing. The demand for oil is constantly increasing. China has changed from an oil exporting country to an oil importing country. According to the news released by Sinopec Group in the second half of 2005, in addition to the domestically produced crude oil, we need to import 80 million barrels of crude oil abroad to meet the domestic market demand. After entering 2005, the international crude oil price has risen repeatedly and the crude oil per barrel has exceeded 70 US dollars per barrel. OPEC quoted in August 2005. So can the raw materials for pyrolysis guarantee the source? For example, Henan Province can recover 4 million tons of used. tires every year from garbage and recycling companies. The development of industrial, and transportation industries, a large amount of waste oil is also urgently to be treated.

Fourth, the main technical characteristics

1. The key equipment cracking processor of this achievement adopts horizontal rotary structure catalytic cracking process and product chemical extraction technology.

2. The environmental performance of Henan Dongying waste tire pyrolysis plant is perfect. For example, an exhaust gas burner and a flue dust chamber.

3. Solve the color and odor of the product with a simple chemical method.

4. The purity of pure waste plastics is not less than 50%.

5. Waste tire pyrolysis plant design Reasonable manufacturing process Advanced automation level High safety facilities.

6. Widely used for a wide range of applications.

Five, Products and industries suitable for waste tirepyrolysis plant

1. Industrial mixed waste plastics allow multiple wastes to be present at the same time but it is recommended that PE > 70% and PVC < 10%.

2. Waste oil. For example, waste diesel engine oil waste oil waste oil residue and so on.

3. Waste rubber tires.

4. The waste cable skin is recommended to be dechlorinated before refining.

5. Waste crude oil.

6. Waste PMMA polymethyl methacrylate regeneration.

Sixth, security

Safety of waste tire pyrolysis plant. In the production process of waste tire pyrolysis plant, the main component of the non-liquefiable exhaust gas is a direct danger of the direct combustion of C1 to C4 alkanes. Before we burn it as a fuel in our current production process, we first pass it through the first safety device of the waste tire pyrolysis plant and then pass it through the second safety device gas nozzle to achieve safe production.

Seven, environmental protection

DOING waste tire pyrolysis plant exhaust gas and waste liquid deal way

Waste tire pyrolysis plant handles the three wastes in the production process.

1.Exhaust gas

Through the safety device water seal and gas nozzle full combustion, it eliminates the exhaust gas pollution and saves a lot of fuel smoke and dust. The patented product of our company---the desulfurization dust collector can meet the national emission standards.

2. Waste liquid

The oil will produce some weakly acidic wastewater during the treatment process (approximately 50 kg of wastewater will be produced for each ton of oil produced). After adding neutralization and neutralization, the neutral wastewater is filtered through three stages to be harmless, and then discharged to a dedicated evaporation processor. The heat source is evaporated by the flue heat of the main processor.

3. Waste solids

After the waste tire is catalyzed by thermal cracking, some solid residue will account for about 5% to 10% of the weight of the waste tire. Its main component is carbon black. It can be used as a raw material for the production of industrial carbon black or as an additive in various raw materials.

Eight, conclusion

According to the above analysis and calculation, it shows that the use of waste tire pyrolysis plant “turning waste into treasure, benefiting the country and benefiting the people” is technically advanced and feasible, with less investment, more raw materials, quicker results and better prospects. Waste tire pyrolysis plant is the best choice for investing in factories.Waste tyre pyrolysis plant project report is feasible.

DOING 3D waste tire pyrolysis plant

For more details on the feasibility report of waste tire pyrolysis plant, please contact the engineer of Henan Dongying Machinery Equipment Co., Ltd. We will design a reasonable plan according to your needs!

Waste tires

The easiest way to dispose of waste tires is to make recycled rubber powder and refinery. The production of recycled rubber powder restricts the further development of this project due to its unfavorable reasons such as high production cost, narrow sales channels, and long service life of the production of plastic track. Waste tire pyrolysis plant is attracting the attention of the world because of its good sales, fast turnover of liquidity and high profits. For example, the average domestic recycling price of used tires is 800-1000 RMB/ton, and the oil yield of used tires is 40-45%. In addition, the production costs such as fuel, workers' wages, and water charges can still obtain certain profits.

Process for producing fuel oil in a decomposition tank developed by Mitsubishi Heavy Industries of Japan

DOING waste tire pyrolysis plant

DOING waste tire pyrolysis plant working process

It is not necessary to directly load waste tires into sediments, moisture, iron wires and other impurities into a high-temperature atmospheric pressure cracking reactor. Catalytic heating distillate oil vapors and oils can be condensed by a condenser to be liquefied and partially condensed into a non-liquefiable portion of the mixed oil. The condensed mixed oil is burned off at the bottom of the unit first by adding a fractionation processor to heat the oil vapor through the catalytic reforming process, and then the oil vapor is fractionated by the condenser. The base fuel oil is subjected to precipitation filtration chemical treatment to add various additives to form a qualified fuel oil. .

On the basis of various studies, we have established a long and short-term basis, based on actual conditions, and after years of scientific and technological research and design, we have launched “Henan DOING's unique series of pyrolysis plant”. Recycling of waste tires is feasible.

Second, the latest series of waste tire pyrolysis plant several major features

Take DY-10T as an example for the waste tyre pyrolysis plant project report

1. Each set of waste tire pyrolysis plant consists of ten parts:

DOING waste tire pyrolysis plant main parts

1.1. Raw material pretreatment device

1.2. Rapid feeding device

1.3. Integrated rotary cracker

1.4. Automatic safety and environmental protection slag system

1.5. Oil vapor cyclone dust removal device

1.6. Rapid condensing system

1.7. Exhaust gas purification and recovery combustion system

1.8. Heat source supply system

1.9. Heat source environmental dust removal system

1.10. Central electronic control system

2, the first manufactirer in domestic:

2.1 In the design of the cracking processor of the key equipment for waste tire pyrolysis plant, it has completely overcome the unfavorable factors such as local uneven heating and uneven fracture at the bottom of the vertical flat-bottom cracking processor, low output and short service life. The host adopts a horizontal 360-degree rotating structure of 0.4 rpm. /Minute.

2.2 Waste tire pyrolysis plant has a fast and practical feeding and slagging system.

2.3 Efficient gas heating system. In the process of refining the waste tire pyrolysis plant, when the heated gas reaches 150 degrees Celsius, a large amount of gas which cannot be liquefied at normal temperature and normal pressure, methane to butane, is generated.

2.4 Flue dust removal system. The waste tire pyrolysis plant is equipped with a water impact type cyclone dust chamber with a dust removal efficiency of over 95%.

3. The company promises:

The various waste tire pyrolysis plant sold by DOING Company has a perfect after-sales service warranty period, which completely solves the worries of customers.

Third, the product and raw materials market

With the rapid development of the world economy, the momentum of oil shortage is increasing. Since the 1990s, energy has become a major factor restricting the economic development of various countries. It has been proved that the oil on the global land will be mined after 15 years and the search for new energy has become the concern of all countries in the world. The problem. China's vast population is vast With the rapid development of the market economy, the demand for vehicles and machinery is increasing. The demand for oil is constantly increasing. China has changed from an oil exporting country to an oil importing country. According to the news released by Sinopec Group in the second half of 2005, in addition to the domestically produced crude oil, we need to import 80 million barrels of crude oil abroad to meet the domestic market demand. After entering 2005, the international crude oil price has risen repeatedly and the crude oil per barrel has exceeded 70 US dollars per barrel. OPEC quoted in August 2005. So can the raw materials for pyrolysis guarantee the source? For example, Henan Province can recover 4 million tons of used. tires every year from garbage and recycling companies. The development of industrial, and transportation industries, a large amount of waste oil is also urgently to be treated.

Fourth, the main technical characteristics

1. The key equipment cracking processor of this achievement adopts horizontal rotary structure catalytic cracking process and product chemical extraction technology.

2. The environmental performance of Henan Dongying waste tire pyrolysis plant is perfect. For example, an exhaust gas burner and a flue dust chamber.

3. Solve the color and odor of the product with a simple chemical method.

4. The purity of pure waste plastics is not less than 50%.

5. Waste tire pyrolysis plant design Reasonable manufacturing process Advanced automation level High safety facilities.

6. Widely used for a wide range of applications.

Five, Products and industries suitable for waste tirepyrolysis plant

1. Industrial mixed waste plastics allow multiple wastes to be present at the same time but it is recommended that PE > 70% and PVC < 10%.

2. Waste oil. For example, waste diesel engine oil waste oil waste oil residue and so on.

3. Waste rubber tires.

4. The waste cable skin is recommended to be dechlorinated before refining.

5. Waste crude oil.

6. Waste PMMA polymethyl methacrylate regeneration.

Sixth, security

Safety of waste tire pyrolysis plant. In the production process of waste tire pyrolysis plant, the main component of the non-liquefiable exhaust gas is a direct danger of the direct combustion of C1 to C4 alkanes. Before we burn it as a fuel in our current production process, we first pass it through the first safety device of the waste tire pyrolysis plant and then pass it through the second safety device gas nozzle to achieve safe production.

Seven, environmental protection

DOING waste tire pyrolysis plant exhaust gas and waste liquid deal way

Waste tire pyrolysis plant handles the three wastes in the production process.

1.Exhaust gas

Through the safety device water seal and gas nozzle full combustion, it eliminates the exhaust gas pollution and saves a lot of fuel smoke and dust. The patented product of our company---the desulfurization dust collector can meet the national emission standards.

2. Waste liquid

The oil will produce some weakly acidic wastewater during the treatment process (approximately 50 kg of wastewater will be produced for each ton of oil produced). After adding neutralization and neutralization, the neutral wastewater is filtered through three stages to be harmless, and then discharged to a dedicated evaporation processor. The heat source is evaporated by the flue heat of the main processor.

3. Waste solids

After the waste tire is catalyzed by thermal cracking, some solid residue will account for about 5% to 10% of the weight of the waste tire. Its main component is carbon black. It can be used as a raw material for the production of industrial carbon black or as an additive in various raw materials.

Eight, conclusion

According to the above analysis and calculation, it shows that the use of waste tire pyrolysis plant “turning waste into treasure, benefiting the country and benefiting the people” is technically advanced and feasible, with less investment, more raw materials, quicker results and better prospects. Waste tire pyrolysis plant is the best choice for investing in factories.Waste tyre pyrolysis plant project report is feasible.

DOING 3D waste tire pyrolysis plant

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications