Solid waste tyres pyrolysis plant

The whole pyrolysis system is composed by 13 parts, which are reactor, transmission device, catalytic chamber, cooling tube, heavy tank, oil-water separator, condenser, light oil tank, safety device, vacuum system, dedusting system, draft fan, chimmey. If take waste tyre as raw material, and DY-1-10 type as equipment, the following is the economic benefit analysis of DY-1-10 type equipment:

DOING pyrolysis plant for sale

DOING pyrolysis plant for sale

1.Daily cost:

Raw material:10ton*300.00RMB/ton=3000.00RMB

Fuel:0.4ton*800RMB/ton=320.00RMB

Water and electricity:15kw*20hour*0.71RMB/kw=213.00RMB

Workers’salary:4(persons) *50.00RMB/Person=200.00RMB

Tax(remark):free from tax for environmental protection equipmentTotal:3733.00RMB

2.Daily turnover:

a.Carbon black:10ton*20%=2ton*1500RMB=3000.00RMB

b.Crude oil :10ton*45%=4.5ton*4500RMB/ton=20250.00RMB

Total :23250.00RMB

3.Daily gross profit :

Gross profit=daily turnover-daily cost=23250.00RMB-3733RMB=19517.00RMB

| Technical parameter of solid waste tyres pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyres | Waste tyres | Waste tyres |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about solid waste tyres pyrolysis plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

In the process of heating with absence of oxygen, we can break waste tires down into usable products, such as pyrolysis oil and carbon black, which both have several applications:

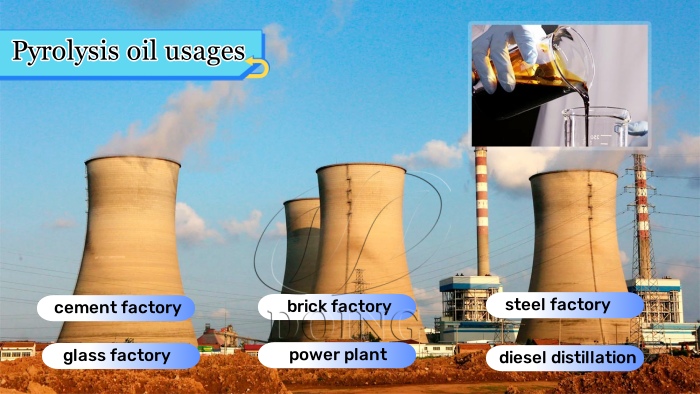

Applications of pyrolysis oil:

1. Fuel: One of the primary uses of pyrolysis oil is as a fuel. It can be used directly in industrial boilers, furnaces, and diesel engines after refining and purification.

2. Power Generation: Pyrolysis oil can be used as a fuel to generate electricity in power plants. It can replace conventional fuels like diesel or natural gas in this application.

3. Heating: It can be used for heating applications in industries or for residential heating systems, similar to how traditional heating oil is used.

Applications of obtained pyrolysis oil

Applications of obtained pyrolysis oil

4. Chemical Feedstock: Pyrolysis oil can be further refined to produce various chemical compounds used in industries, such as phenols, benzene, toluene, and xylene (BTX), which are important in the production of plastics, resins, and other materials.

5. Additive in Cement Kilns: It can also be used as an alternative fuel or fuel additive in cement kilns, contributing to energy efficiency and reducing emissions.

6. Refine to diesel: Pyrolysis oil can be refined to diesel oil with the waste oil distillation machine, the obtained diesel can be used in heavy machineries, diesel generators, boiler, etc.

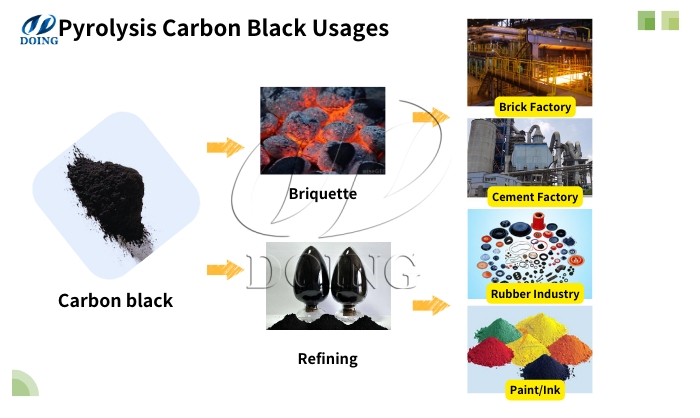

Applications of carbon black:

The solid residue left after pyrolysis, known as carbon black, can be used in various applications such as reinforcing filler in rubber products, pigments, and as a conductive agent in batteries.

Applications of obtained carbon black

Applications of obtained carbon black

Here DOING provides various types of waste tyre pyrolysis plants, including skid-mounted type, batch type, semi-continuous type and fully continuous type, more detailed information, welcome to consult!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications