Recycling plastic to fuel conversion process plant

Recycling plastic to fuel conversion process plant

Nowadays,plastic products has replace many other bags/containers materials.

Because of the plastic bags is very popular in our daily life, plastics waste is a significant portion of the total municipal solid waste (MSW).

Waste plastic scenario in India:

Total plastic waste generation is 36 to 40 MMT/Annum in India, and 60 % segregated wastes is recycled, 40 % is disposed by indiscriminate land disposal, (About 10 % of MSW is plastics).

Source of waste plastic:

Institutional: Packing,CDs and DVDS/computers/Discarded spare parts/components/storage containers.

Plastic waste: Like medical, pharmaceuical packing/blood bags&accessories/syringes/injection vials.

Domastic: Water bottles/plastic dinnerware/toys/packing containers&bags.

Industrial: Advertising materials/storage pellets/packing&insulation items/pipes/broken containers and linings.

But how can we deal with the waste plastic bags? and turn the waste plastic into energy for reusing.

DOING Recycling plastic to fuel conversion process plant can efficiently deal with the waste plastic bags into fuel oil without secondary pollution.

Recycling plastic to fuel conversion process plant:

Because of the plastic bags is very popular in our daily life, plastics waste is a significant portion of the total municipal solid waste (MSW).

Waste plastic scenario in India:

Total plastic waste generation is 36 to 40 MMT/Annum in India, and 60 % segregated wastes is recycled, 40 % is disposed by indiscriminate land disposal, (About 10 % of MSW is plastics).

Source of waste plastic:

Institutional: Packing,CDs and DVDS/computers/Discarded spare parts/components/storage containers.

Plastic waste: Like medical, pharmaceuical packing/blood bags&accessories/syringes/injection vials.

Domastic: Water bottles/plastic dinnerware/toys/packing containers&bags.

Industrial: Advertising materials/storage pellets/packing&insulation items/pipes/broken containers and linings.

But how can we deal with the waste plastic bags? and turn the waste plastic into energy for reusing.

DOING Recycling plastic to fuel conversion process plant can efficiently deal with the waste plastic bags into fuel oil without secondary pollution.

Recycling plastic to fuel conversion process plant:

Recycling plastic to fuel conversion process plant

Advantages of Recycling plastic to fuel conversion process plant:

1.Whole plastic feed, no need to break, which reduces cost.

2.Adopt multilevel cooling circulation to get more fuel oil.

3. Discharge process through pulse dust removal processing, no dust emissions.

4. Easy operation, high efficiency and 2-3 people to operate.2.Adopt multilevel cooling circulation to get more fuel oil.

3. Discharge process through pulse dust removal processing, no dust emissions.

5.Recycling plastic to fuel conversion process plant adopts fully automatic submerged arc welding process, through x-ray detection, to improve the security of plant.

Recycling plastic to fuel conversion process plant technical data:

| Technical parameter of Recycling plastic to fuel conversion process plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about recycling plastic to fuel conversion process plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

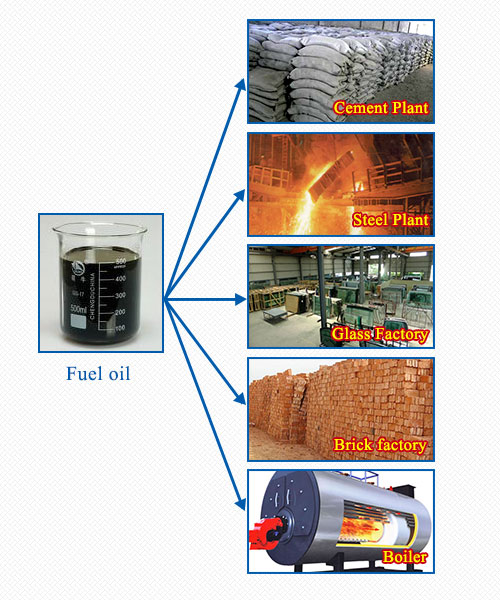

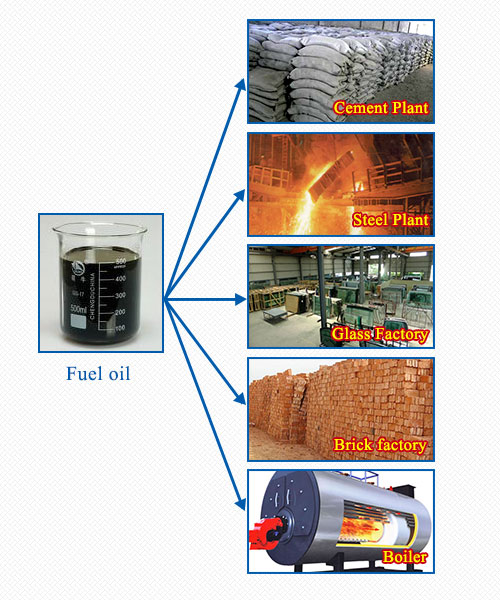

Recycling plastic to fuel conversion process plant final application:

Fuel oil application

Fuel oil from recycling plastic to fuel conversion process plant are used in below industries:

A.Power plant factory

B.Glass factory

C.Cement factory

D.Ceramic fatory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

1.A. Waste plastics, Used bottles,used tyres, used bags, farming waste , other

B.Medical waste

C.Oil sludge , waste oil ,black oil ,oily solid

D.Other living waste

Fuel oil application

A.Power plant factory

B.Glass factory

C.Cement factory

D.Ceramic fatory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

1.A. Waste plastics, Used bottles,used tyres, used bags, farming waste , other

B.Medical waste

C.Oil sludge , waste oil ,black oil ,oily solid

D.Other living waste

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications