Plastic waste management project recycling machine

Plastic waste management project recycling machine

The quantum of solid waste plastic increasing due to increase in population, developmental activities, changes in life style, and socio-economic conditions, pastics waste is a significant portion of the total municipal solid waste (MSW). It is estimated that approximately 10 thousand tons per day (TPD)of plastics waste is generated i.e. 9% of 1.20 lacs TPD of MSW in the country. The plastics waste constitutes two major category of plastics.

Plastic waste management project recycling machine of Doing is to tranform waste tires,waste plastic to fuel oil .The raw material of Plastic waste management project recycling machine is waste tires ,waste plastic,waste rubber and so on.ThePlastic waste management project recycling machine can help you to deal with solid waste plastic, collect oil into tank and slag the carbon black powder. The collect oil can be sold directly in the market.

Plastic waste management project recycling machine of Doing is to tranform waste tires,waste plastic to fuel oil .The raw material of Plastic waste management project recycling machine is waste tires ,waste plastic,waste rubber and so on.ThePlastic waste management project recycling machine can help you to deal with solid waste plastic, collect oil into tank and slag the carbon black powder. The collect oil can be sold directly in the market.

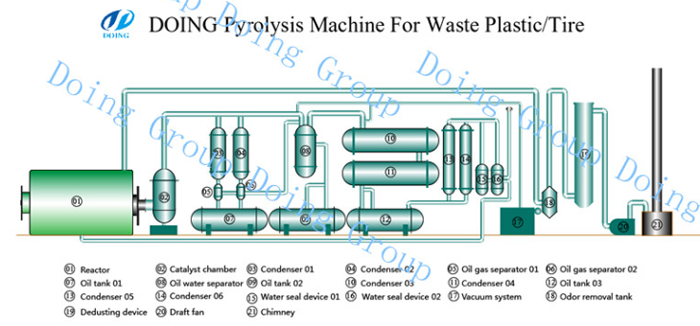

Plastic waste management project recycling machine working process

When using this plastic waste management project recycling machine to dispose waste plastics, the pre-treated plastics will firstly be conveyed to the moving horizontal pyrolysis reactor through feeder system. Then the plastics will take a series of pyrolysis reactions under the action of catalyst. Finally we can get pyrolysis oil and carbon black. Both of them are available energy. For example, the plasitc pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel.

Plastic waste management project recycling machine technical data:

Preparation before the customer's installation:

| Technical parameter of Plastic waste management project recycling machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic, waste tyre, waste rubber |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about plastic waste management recycling pyrolysis machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Plastic waste management project recycling machine final product and application:

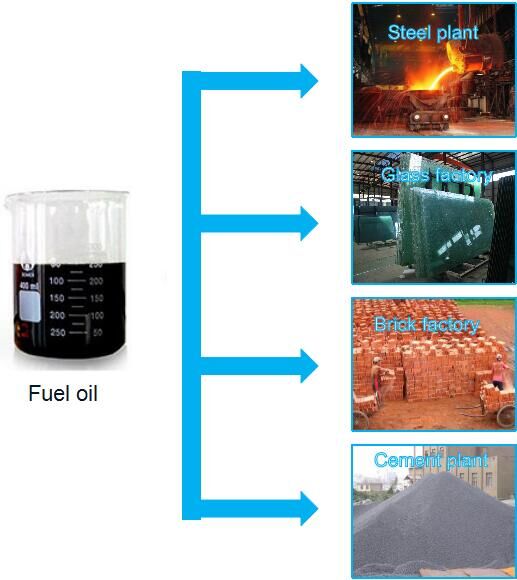

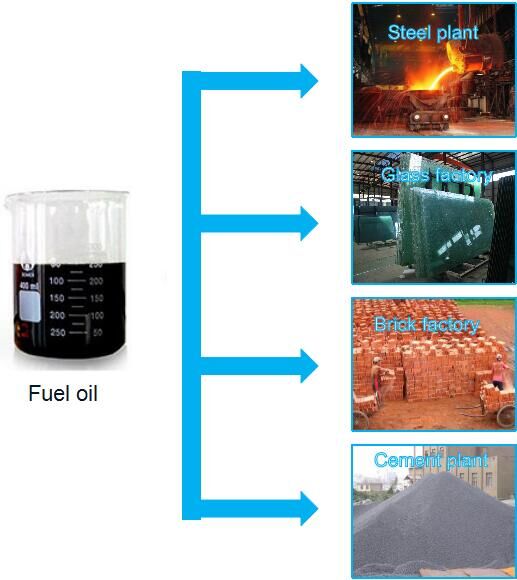

Fuel oil application

1.Fuel Oil (40% to 45%)

The main application of oil products produced by our w is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Carbon Black (30% to 35%)

The second product of waste plastic management pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive.

Fuel oil application

The main application of oil products produced by our w is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Carbon Black (30% to 35%)

The second product of waste plastic management pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications