Hot selling waste rubber pyrolysis machine

1.waste rubber pyrolysis machine working process

waste rubber pyrolysis machine

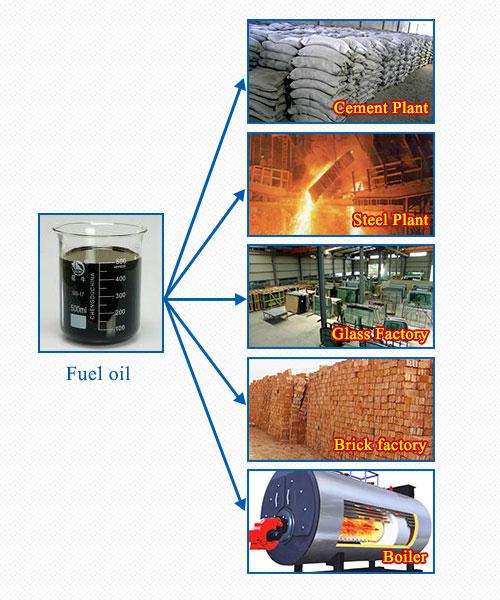

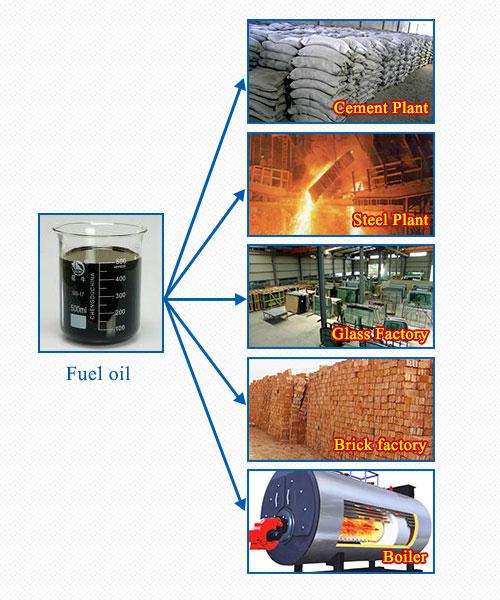

Feed waste rubber into the reactor with auto-feeder, seal the reactor gate and begin to heat the reactor by burning fuel materials in the combustion system, the fuel material can be coal, wood, natural gas and fuel oil. There is a thermocouple installed at the oil gas outlet valve to test the temperature of the oil gas, when thermocouple shows a certain temperature, the oil gas will come out and flow into the cooling system and be converted into liquid oil. At the same time, the oil gas conations CH4, C2H6, C3H8, C4H10 and H2 which cannot be cooled under normal pressure will be recycled back to combustion system to burn as fuel material. The dust and sulfur gas will be removed by the dust removing system. After the gas oil run out, there are slags (carbon black) inside of the reactor,.

As waste rubber pyrolysis machine manufacturer-DOING will provide customer a good quality machine with adopt fully automatic vacuum carbon black discharging system that extend the service time.

Choosing the suitable raw material is important for customers, it concerns the real profit you can get from your material. Not all kinds of waste rubber can get oil, if you want to get crude fuel oil with high oil yield from waste rubber, please refer to the following form: Here I need to stress that the oil rate only for your reference, as different rubber different result, such as some rubber has very dirty slag, and the rubber is very wet.

waste rubber pyrolysis machine

As waste rubber pyrolysis machine manufacturer-DOING will provide customer a good quality machine with adopt fully automatic vacuum carbon black discharging system that extend the service time.

Choosing the suitable raw material is important for customers, it concerns the real profit you can get from your material. Not all kinds of waste rubber can get oil, if you want to get crude fuel oil with high oil yield from waste rubber, please refer to the following form: Here I need to stress that the oil rate only for your reference, as different rubber different result, such as some rubber has very dirty slag, and the rubber is very wet.

| Technical parameter of waste rubber pyrolysis machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste rubber | Waste rubber | Waste rubber |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about High oil rate waste rubber pyrolysis machine | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

3.Waste rubber pyrolysis machine final product application

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications