Waste rubber to oil pyrolysis plant

1.Waste rubber to oil plant features

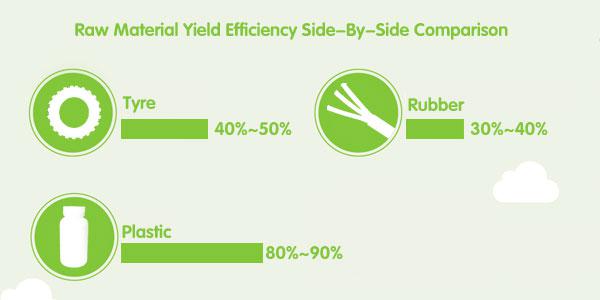

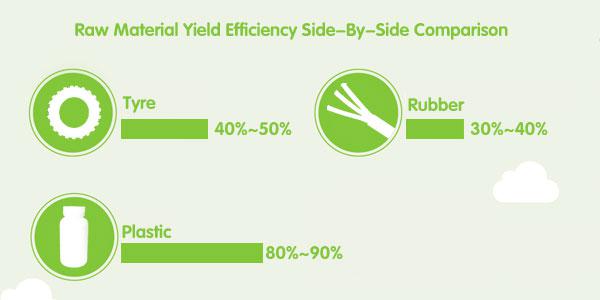

Our waste rubber to oil plant can convert waste rubber into high grade diesel fuel. Waste rubber are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste rubber pyrolysis, this long chain is broken down into smaller chain. The waste rubber to oil machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

Our waste rubber to oil plant can convert waste rubber into high grade diesel fuel. Waste rubber are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste rubber pyrolysis, this long chain is broken down into smaller chain. The waste rubber to oil machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

In waste rubber to oil plant, the polymer waste is not burned, instead it is broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and Charcoal.

In waste rubber to oil plant, the polymer waste is not burned, instead it is broken down into usable finished products like Pyrolysis Oil, Hydrocarbon Gas and Charcoal.

2.Waste rubber to oil plant technical data

| Technical parameter of waste rubber to oil pyrolysis plant | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste rubber | Waste rubber | Waste rubber |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

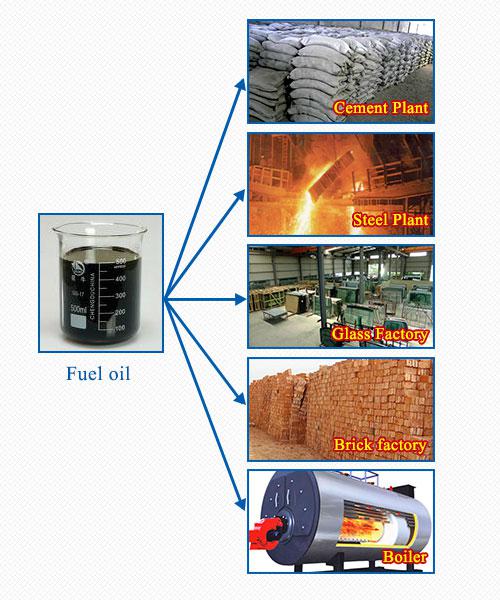

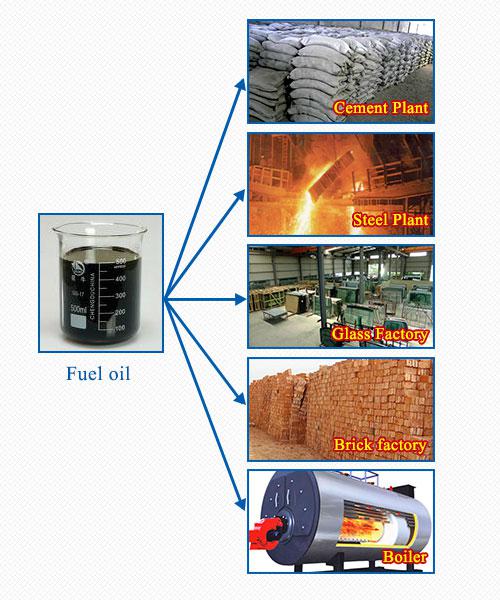

3.Waste rubber to oil pyrolysis plant final product application

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications