Tyre oil refining process plant

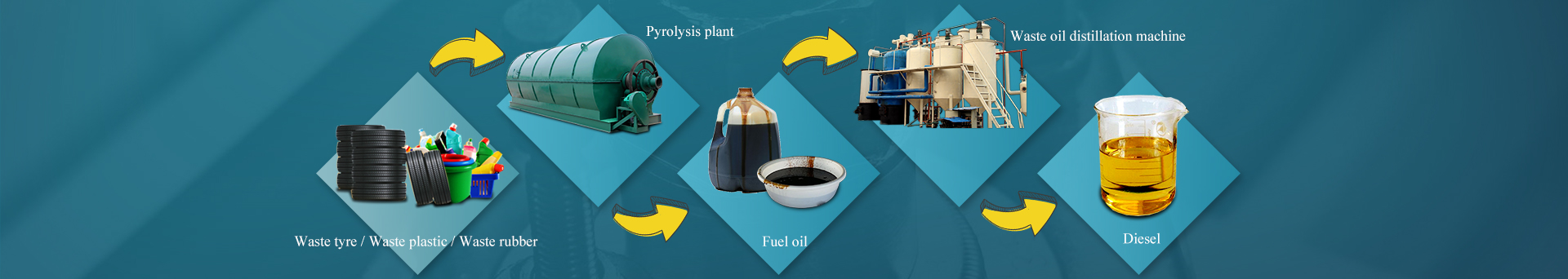

Tyre oil is also referred to tyre pyrolysis oil, which is a kind of fuel oil extracted from waste tyres by waste tire pyrolysis machine. The composition of tyre pyrolysis oil is quite complex, and to meet the demand of some customers to enhance the economic value and application market of tyre oil, here DOING developed the tyre oil refining process plant, which adopts the latest distillation technology and excellent design to refine tyre oil into diesel with high oil yield and good quality.

1. Feeding: put tyre oil into the distillation reactor of the tyre oil refining process plant;

2. Distillation: heat the tyre oil in an oxygen-free environment, the tyre oil begins to boil and vaporize into oil gas with the increase of temperature. The types of oil gas vaporized out at different temperatures are different, so as to achieve the purpose of separating various components.

Work process of tyre oil refining process plant

Work process of tyre oil refining process plant

3. Cooling: oil gas passes through the condensation system and cooled into liquid diesel oil, while other uncondensable gas will be purified as heating energy;

4. Purifying: the collected diesel oil is further purified by a deep purification system to make it clean and bright, and then collected diesel oil into the storage tank. Here DOING provides two purifying technologies: for the common type tyre oil refining process plant, we use the acid and alkali catalysts to purify the diesel oil; for the latest type tyre oil refining process plant, we use the solid catalyst to purify the diesel oil; (these two catalyst technologies both have excellent purifying performance.)

Two types of DOING tyre oil refining process plant

Two types of DOING tyre oil refining process plant

5. Collecting: the cooled liquid diesel oil will be stored in the oil tank, the obtained solid asphalt product will be discharged automatically;

1. The whole production process of tyre oil refining process plant is smokeless and odorless with good environmental protection.

2. Adopt circulating water cooling system to reduce the operation cost of tyre oil refining process plant.

3. The tyre oil refining process plant adopts a precise process and has high oil yield.

DOING tyre oil refining process plant for sale

DOING tyre oil refining process plant for sale

4. Indirect heating is adopted to extend the service life of the reactor.

5. Factory directly supply and mature developing and manufacturing teams to ensure the quality of tyre oil refining process plant.

6. Offer a customized machine scheme with abundant project experience and various types and capacities of tyre oil refining process plant for your reference;

| Tyre oil refining process plant Technical parameter | |

| Machine type | Semi-continuous type |

| Inputs | Tire plastic pyrolysis oil, waste oil, used motor engine oil; |

| Outputs | Diesel, asphalt |

| Model | DY-D-0.1-14TPD |

| Thickness | 14/16/18mm |

| Heating method | Indirect heating, with fast heating system as an option |

| Structure form | Vertical (easy cleaning and maintenance) |

| Operating pressure | Constant pressure |

| Slagging type | Automatic slag |

| Reactor material | Q345R/Q245R boiler plate/304/316/310S Stainless plate |

| Heating fuel | Fuel oil, natural gas, coal, wood |

| Cooling type | Circulating water cooling |

| Diesel yield | 80%-90% |

| Service life | Average 7 years |

Diesel: The obtained diesel oil can be used in tractors, trucks, diesel generators, ships and so on.

Applications of obtained diesel and asphalt

Applications of obtained diesel and asphalt

Asphalt: The obtained asphalt can be used for paving or make further refinery.

And due to the wide application and market of the final products obtained from the tyre oil refining process plant, many customers obtained huge profits from the project. The following is a brief profit analysis of DOING tyre oil refining process plant based on our market survey and customers' feedback (take our 5TPD tyre oil refining process plant as an example):

Profits analysis of DOING tyre oil refining process plant

Profits analysis of DOING tyre oil refining process plant

Over the past 14 years, DOING tyre oil refining process plant has gone through several generations of technological updates and improvements, committed to meet the demands of our customers. And we have cooperated with many customers in various countries, such as Malaysia, Ghana, Colombia, Mali, South Africa, Indonesia, Mexico, etc., and received lots of good feedback.

Projects of DOING tyre oil refining process plants

Projects of DOING tyre oil refining process plants

If you are also interested in our tyre oil refining process plant, welcome to contact us!

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications