Turning tyre into diesel fuel plant

Turning tyre into diesel fuel plant

Are you facing waste tyre pollution problem? Is waste tyre really a waste?

Our answer is “No”. Because we have turning tyre into diesel fuel plant, which means we can get fuel oil from waste tyre and change waste tyre into great treasure.

But what is the technology of turning tyre into diesel fuel plant?

Waste tyre pyrolysis plant

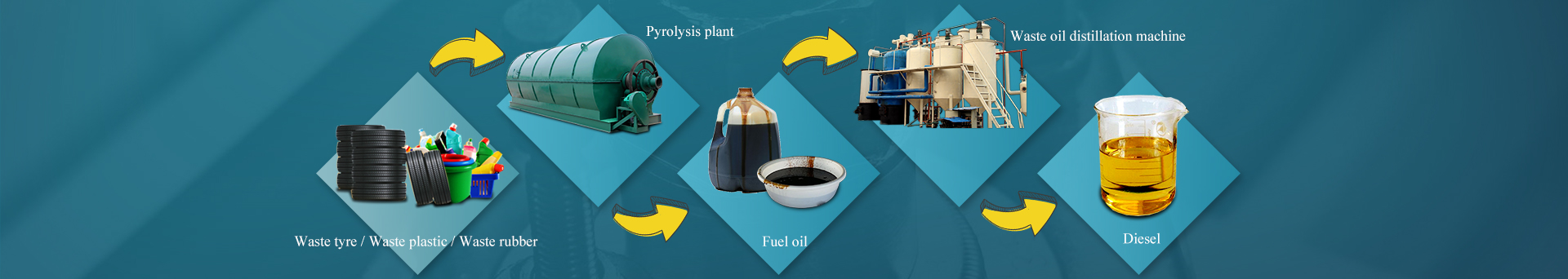

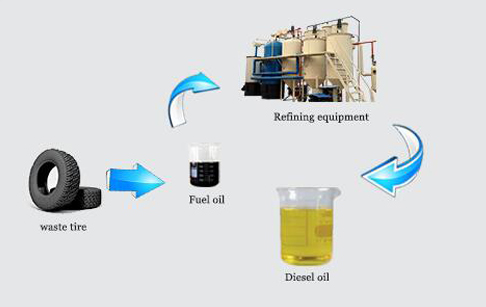

First step---tyre pyrolyzed into heavy fuel oil.

Tyre pyrolysis plant processing waste tyre to diesel

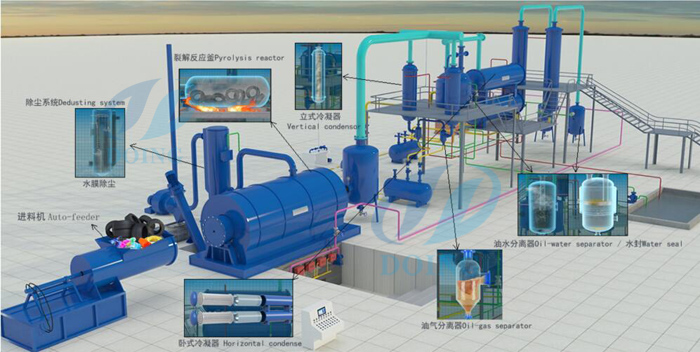

You know, tyre pyrolysis is a thermo decomposition of tyre polymer, since waste tyres are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross linked or straight chain.During high temperature processing, this long chain( C-50,000 to C-2,00,000) is broken down into smaller chain (C-1 to C-4 & C-5 to C-23). Among which, C5-C23 is oil got from long chain tyre polymer.

Second step---refine tyre heavy fuel oil into diesel fuel

Turning tyre into diesel fuel plant

Turning tyre into diesel fuel plant working process

Turning tyre into diesel fuel plant distillaton tyre oil to diesel

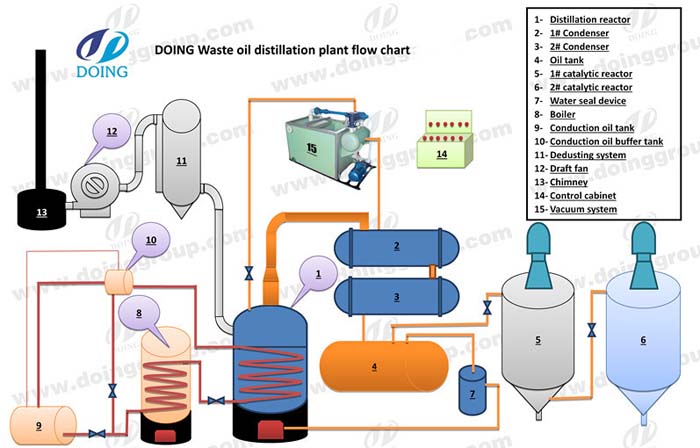

Secondly, heat the tyre pyrolysis oil in non-oxygen environment, which will start to boil and evaporate;

Thirdly, put those vapors through a cooling pipe and the vapors will be condensed to liquid and some of the vapors with shorter hydrocarbon lengths will remain as a gas;

Fourthly, the exit of the cooling pipe is then going through a bubbler containing water to capture the last liquid forms of fuel and leave only gas that is then burned;

Finally, this kind of oil will be piped into deep purifying system with acidity and alkaline cleaning device as well as pressure filtering system. And then, we can get qualified diesel fuel.

Turning tyre into diesel fuel plant Technical parameter

| Technical parameter of Waste tyre and plastic oil to diesel fuel distillation plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Turning tyre into diesel fuel plant diesel fuel application

Turning tyre into diesel fuel plant

1. The complete set of unit produces no smoke and smell with favorable effects of environmental protection.

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts indirect heating technology, which prolongs the machine service life; the average life time is about 7 years.

The diesel can application totractors ,trucks,ships and generator

Diesel fuel application

Turning tyre into diesel fuel plant

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts indirect heating technology, which prolongs the machine service life; the average life time is about 7 years.

The diesel can application totractors ,trucks,ships and generator

Diesel fuel application

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications