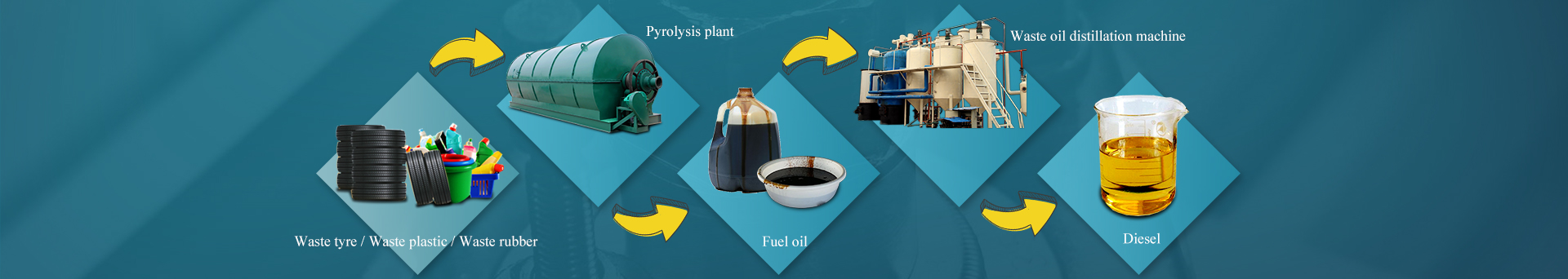

Tyre pyrolysis oil distillation process plant

Tyre pyrolysis oil plant

Tyre pyrolysis oil distillation process plant

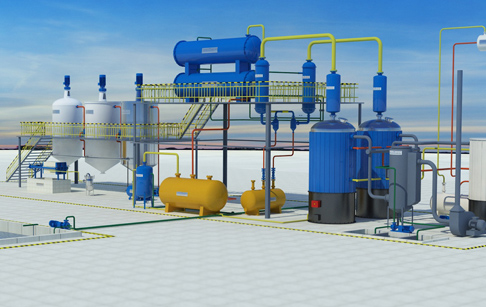

3 D picture of waste tyre oil distillation plant

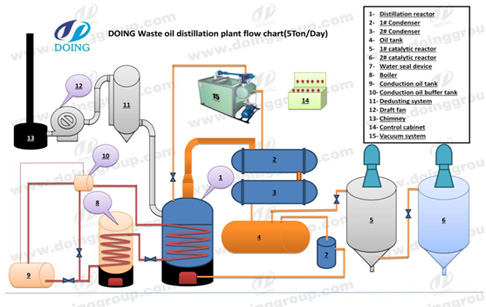

The Tyre pyrolysis oil distillation process plant with a high yield project is easy to operate:

Tyre pyrolysis oil distillation process plant

2. Control temperature to ensure get good quality diesel, and cooling oil gas to get diesel;

3. Pump diesel to odor removal and color removal systems automatically;

4. Get good quality diesel.

Doing Tyre pyrolysis oil distillation process plant is the latest technology in China pyrolysis industry, we refreshed the design to save heating time and increase oil yield.

Tyre pyrolysis oil distillation process plant

| Technical parameter of tyre pyrolysis oil distillation process plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tyre oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

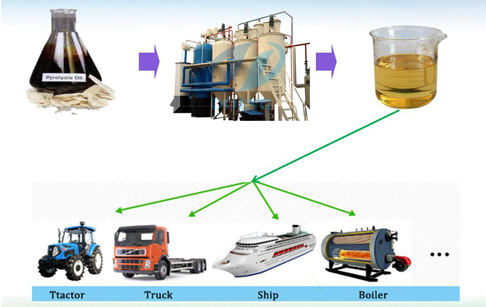

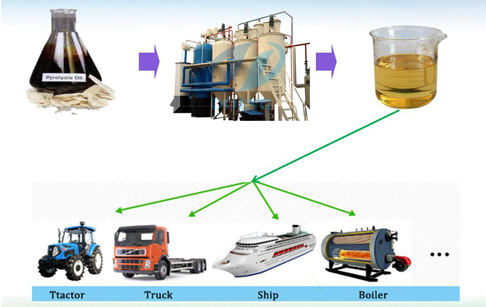

Tyre pyrolysis oil distillation process plant final product diesel application

The final diesel oil of waste pyrolysis distillation process plant can used for tractors, trucks, ships and generator etc:

Diesel application

The final diesel oil of waste pyrolysis distillation process plant can used for tractors, trucks, ships and generator etc:

Diesel application

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications