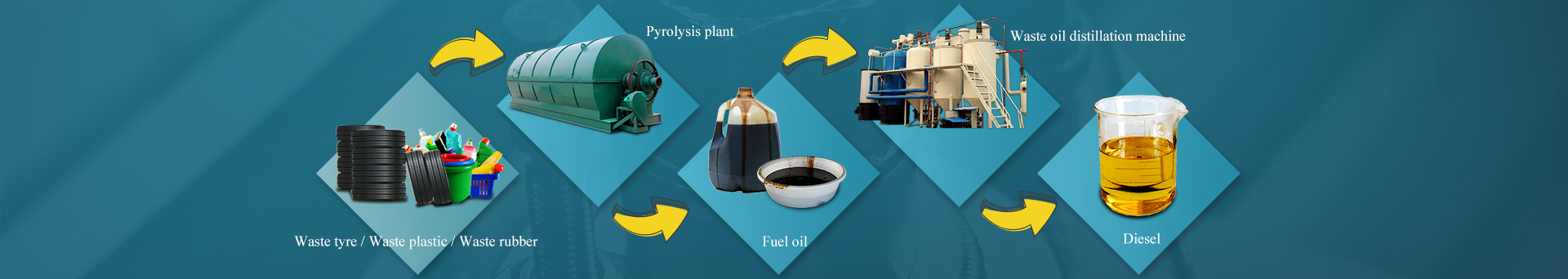

Converting waste motor oil to diesel fuel refining plant

In recent years, recycling of the waste motor oils and utilizing of the products as fuels have become important topics for researchers. Most of the waste motor oils are generally obtained from petroleum resources. The used or waste motor oils can be refined and treated to produce fuels or motor oil base stock. On the other hand, the waste motor oils pose an environmental hazard due to both their metal content and other contaminants. The high - volume waste motor oils can be turned into valuable fuel products by refining and treating processes.

Converting waste motor oil to diesel fuel refining plant

Convert waste motor oil to diesel fuel oil refinery plant distills the incoming crude oil, pyrolysis oil, waste oil or lubrication oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc, the oil yield will be 85%-90%, the by-products are 10%-15% slag and syngas.

Converting waste motor oil to diesel fuel refining plant

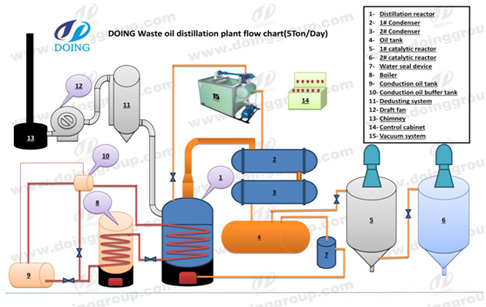

Converting waste motor oil to diesel fuel refining plant process:

Converting waste motor oil to diesel fuel refining plant process

1. Pump the waste motor oil into reactor by oil pump.

2. Use coal/wood/natural gas/fuel oil/electricity heating the reactor.

3. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

4. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

5. When use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

6. The exhaust gas will go into the chimney sucked by draft fan, when emission the exhaust gas will become steam, no pollution.

2. Use coal/wood/natural gas/fuel oil/electricity heating the reactor.

3. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

4. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

5. When use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

6. The exhaust gas will go into the chimney sucked by draft fan, when emission the exhaust gas will become steam, no pollution.

| Technical parameter of converting waste motor oil to diesel fuel refining plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste motor oil, waste tire oil, plastic oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

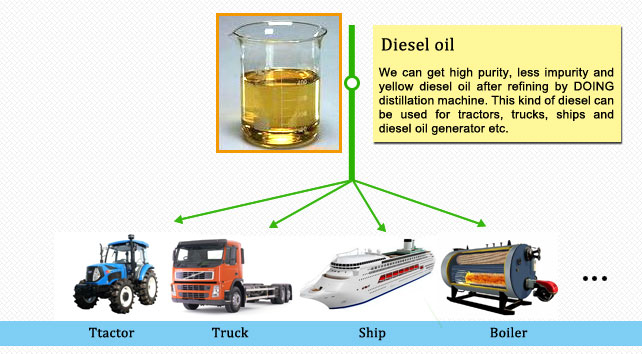

Diesel fuel oil application

Converting waste motor oil to diesel fuel refining plant can purify waste motor oil, waste tire oil, plastic oil; waste engine oil to diesel, the final product-diesel can be used for tractors, trucks, and diesel oil generators, ships etc.contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications