Used engine oil to diesel recycling system

Used engine oil

The production of waste automotive engine oil (WO) is estimated at 24 million tons each year throughout the world, posing a significant treatment and disposal problem for modern society. WO, containing a mixture of low and high molecular weight aliphatic and aromatic hydrocarbons, also represents a potential source of high - value fue l and chemical feedstock. The preferred disposal option in most countries is incineration and combustion for energy recovery, though vacuum distillation and hydro - Used engine oil to diesel recycling system can dispose the problems.

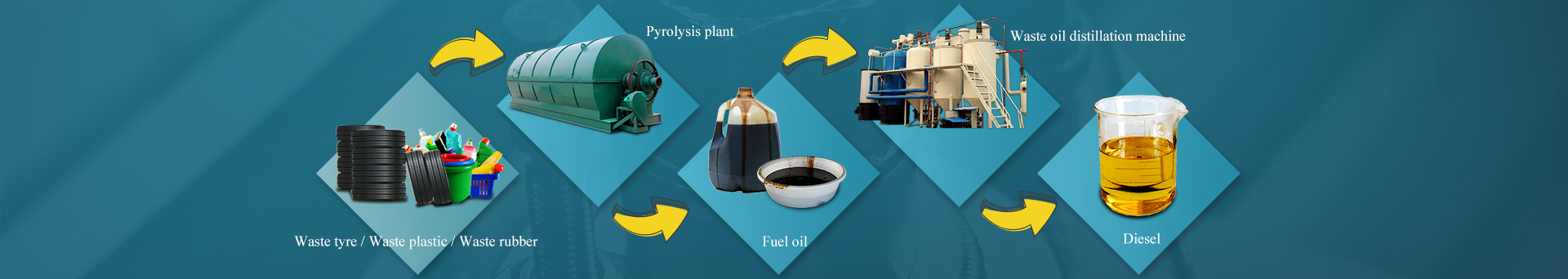

Used engine oil to diesel recycling system

Used engine oil to diesel recycling system working process

Used engine oil to diesel recycling system

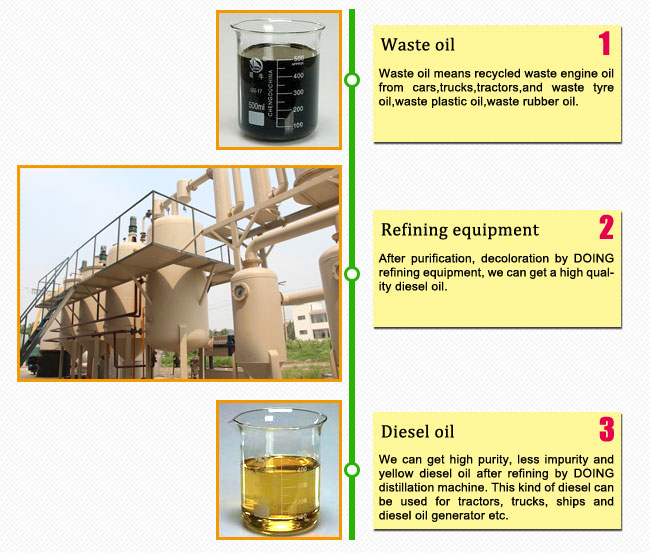

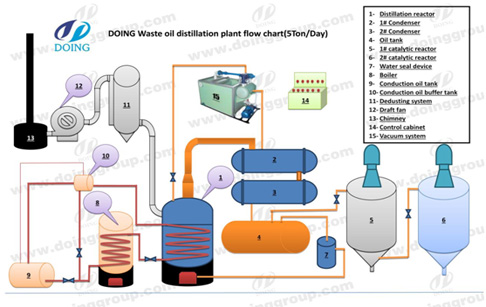

1. Put tyre oil/plastic oil/engine oil into distillation reactor with oil pump

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

Used engine oil to diesel recycling system advantage

100% safety assurance:1. Safety devices such as alarming device, pressure gauge, safety valve. If there is some pressure in the reactor, the alarming device will ring and even no workers hear it, it does not matter as we have the reducing pressure device automatically.

2. Vacuum system can ensure the plant running in a safety condition. Make the whole refining processing be on a normal pressure to avoid accident.

| Technical parameter of used engine oil to diesel recycling system | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel application of used engine oil to diesel recycling system

| Oil yield of different material: | ||

| No. | Name | Oil yield |

| 1 | Used oil | 85%-90% |

| 2 | Waste plastic oil | 95% |

| 3 | Waste engine oil | 85%-90% |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications