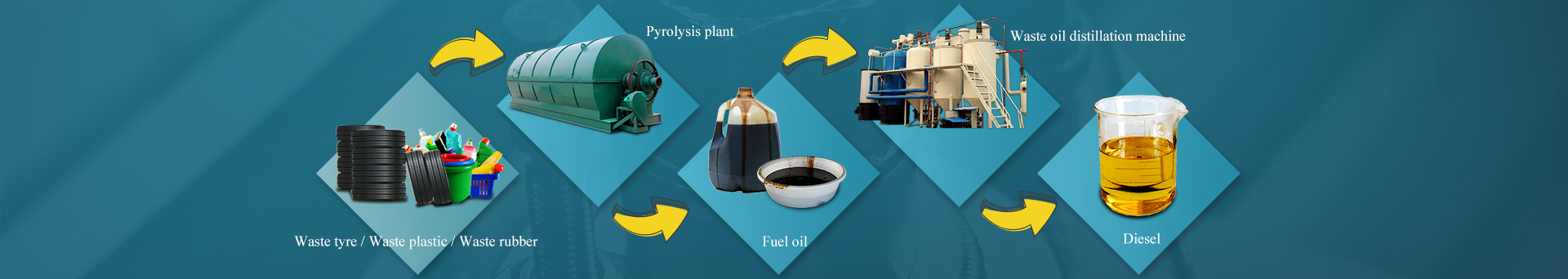

Crude oil distillation process

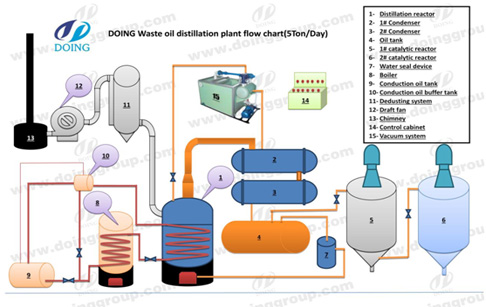

Crude oil distillation machine

Crude oil distillation process

First of all, the thermal oil is poured into the heat-conducting system for preheating.

Second, crude oil is poured into the reactor and the reactor is heated. The crude oil in the reactor was distilled at high temperature, and the residue in the crude oil was distilled off. After filtration, clean gas oil and gas were obtained.

Once again, light oil and gas enter the condensing system under the action of high and low pressure, and is liquefied when it is cooled and falls into the oil tank.

Then, the exhaust gas wastes from pyrolysis in the furnace are treated, filtered, and discharged to the environmental protection department's assessment standards.

Finally, the filtered residue, asphalt, is distilled and discharged from the furnace.

Crude oil distillation machine Technical parameter

| Technical parameter of crude oil distillation machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications