Used engine oil recycling machine/High Diesel Yield

Used engine oil recycling machine for sale

Used engine oil recycling machine for sale

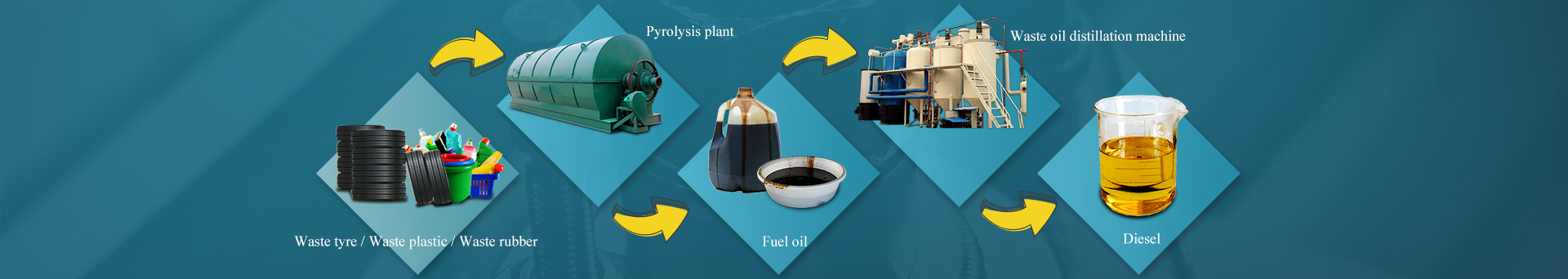

Waste oil refers to waste oil that has been replaced by various machines, vehicles and ships, such as used engine oil, waste motor oil, old lubricant oil, black oil, waste tire plastic pyrolysis oil, black oil, etc. Its production process is due to the fact that the lubricating oil during use is contaminated by external pollution, resulting in a large amount of colloidal oxides, thereby reducing or even losing control over friction, reducing wear, cooling and cooling, sealing and isolation, and reducing vibration and other effects that must be replaced.

So how do you deal with these changed waste oils? In response to this social problem, Doing Group has developed a used engine oil recycling machine(also called waste oil distillation plant or used oil refinery machine), which can obtain clean and transparent non-standard diesel oil through high-temperature distillation and condensation.

Two types of used engine oil recycling technologies

Two types of used engine oil recycling technologies

DOING used engine oil recycling machine can effectively remove the solid particles, colloidal matter, black color and unpleasant odour from waste oils like used engine oil by acid-alkali treatment and filtration, or solid catalysts technology.

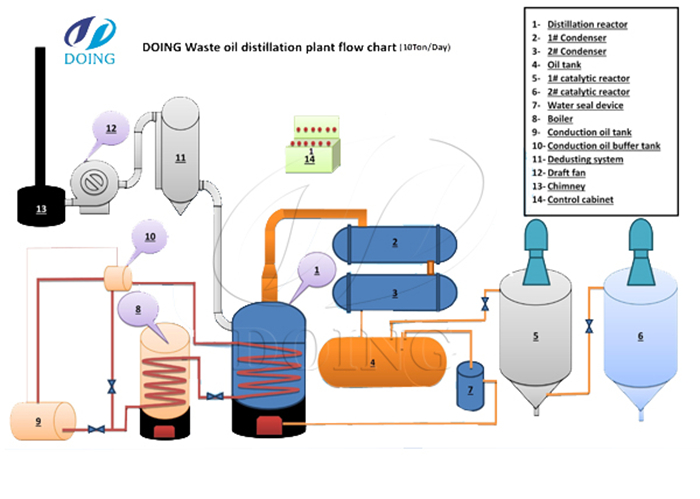

Each step of the used engine oil to diesel recycling process is designed to ensure the safe, energy-saving, environmental friendly, pollution-free waste oil recycling. For better understanding, DOING engineer team had designed the 3D picture of used engine oil recycling machine working process for your reference.

Used engine oil recycling machine working process

Used engine oil recycling machine working process

1. Add waste oil to the reactor and start heating;

2. When the temperature rises to a certain extent, high-temperature distillation chemical reactions can be performed to separate the impurities from the waste oil.

3. Condensate the separated oil and gas, which will be liquefied into light oil and flow into the tank.

4. Automatically pump diesel to remove odor and color removal system;

5.Finally, get high quality diesel with qualified color and smell.

Advantages of DOING used engine oil recycling machine

Advantages of DOING used engine oil recycling machine

1. The rapid heating system of the used engine oil recycling machine adopts the heating of the circulating heating medium and the fuel at the same time, on the one hand, the fuel can be saved, and on the other hand, the distillation speed can be accelerated.

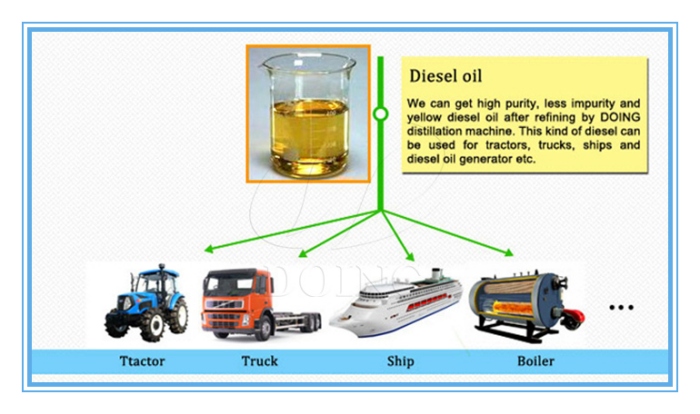

2. The diesel oil produced through the standard used engine oil recycling refining machine is brownish yellow. If you want to get better color diesel, we can also provide a deep purification system, and finally you can get pale yellow diesel products with high economic values for sale.

3.Used engine oil recycling machine produced by Henan Doing Group has been certified by CE, ISO, SGS, etc. By equipped with professional multiple stage cooling pipes with lager cooling area and more effective cooling effect, DOING used oil recycling machine can convert waste oil into diesel at a higher yield, creating higher profits.

4.DOING used oil recycling machine adopts advanced exhaust gas purification system, which can make the emission in line with European pollution control standards.

| Technical parameter of used engine oil recycling machine for sale | |

| Items | Contents |

| Model | DY-100/500kg, DY-1t, DY-5t, DY-10t, DY-14t… |

| Raw material | Used engine oil, heavy oil, mazut, waste motor oil, waste tire crude oil, plastic pyrolysis oil, etc. |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 80-85%, depends on the contents of waste oil |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 14/16/18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡, depends on machine scales and confifurations |

The main products of used engine oil recycling machine are diesel and asphalt(bitumen). Among them, the oil production is about 85%, and the rest includes 10% of bitumen and 5% of excess gas. Their main uses are as follows:

1. Diesel oil: Mainly used for heavy machinery, low speed engine, heavy machinery, diesel generators and boilers, etc., such as tractors, digging machine, trucks, ships, loading machine, road roller and so on.

Usages of diesel extracted from used oil recycling machine

Usages of diesel extracted from used oil recycling machine

2. Asphalt: Mainly used for paving or sent to asphalt plants for re-refining.

3. Excess gas: being recycled to the furnace as an auxiliary heating fuel.

Used oil recycling plant project cases

Used oil recycling plant project cases

Used engine oil recycling machines manufactured by Henan Doing Company have been hot sales to many countries and regions, such as Mexico, China, Malaysia, Indonesia, Nigeria, India, Ghana, Haiti, America, South Africa, etc. If you are interested in customizing used engine oil recycling machines here, we will offer one year warranty and one-stop services, such as making waste oil recycling plant drawing, machine testing, installation and commissioning, workers training, etc. Welcome to contact us to talk about your waste oil recycling business now.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications