Waste oil recycling to diesel plant

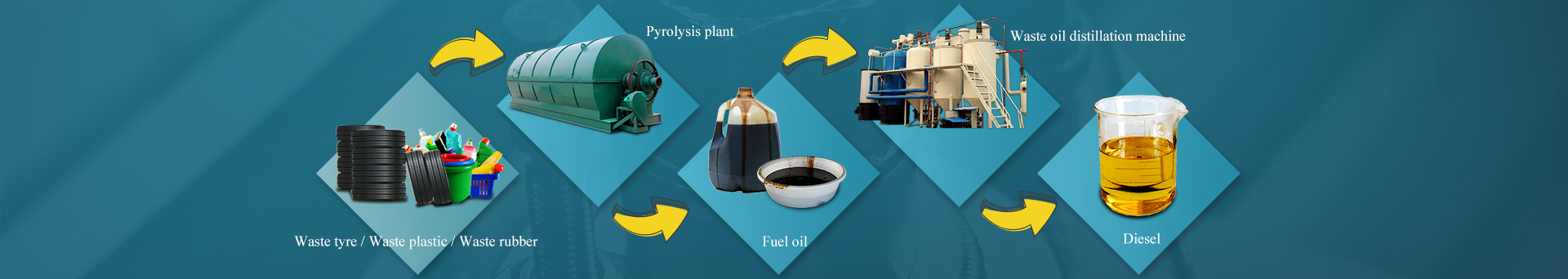

Waste oil recycling to diesel plant is specially designed and manufactured for recycling waste oil, tire cracking oil, and plastic cracking oil. Waste oil recycling to diesel plant can extract waste oil, tire pyrolysis oil and plastic pyrolysis oil into diesel oil.

Waste oil recycling to diesel

Waste oil recycling to diesel

The unique advantages of waste oil recycling to diesel plant are as follows:

1. Waste oil recycling to diesel plant using steel frame design structure, covers a small area;

2. Waste oil recycling to diesel plant using building block structure design, easy to control;

3. The structure design of waste oil recycling to diesel plant is reasonable, so that the installation and maintenance of waste oil recycling to diesel plant is very convenient;

4. Waste oil recycling to diesel plant using insulation layer structure design, can reduce heat loss to achieve energy saving;

5. The waste gas from waste oil recycling to diesel plant is processed by the smoke cleaning system, and the exhaust emission is pollution-free to the environment.

Waste oil recycling to diesel plant

Waste oil recycling to diesel plant

The safety management measures for waste oil recycling to diesel plant:

1. Decentralized management

In order to ensure safety, the waste oil recycling to diesel plant is equipped with pressure gauge, temperature controller and safety valve at each key position, so that workers can control the operation of any part at any time.

2. Centralized control

Depending on the customer's needs, waste oil recycling to diesel plant can be equipped with some high-end sensors. The sensor can send every data to the operation desk timely and accurately, so that the operation floor can be controlled centrally. If there is any problem, the operator can get the information immediately and control the whole situation in time.

Technical parameter of waste oil recycling to diesel plant

| Technical parameter of waste oil recycling to diesel plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

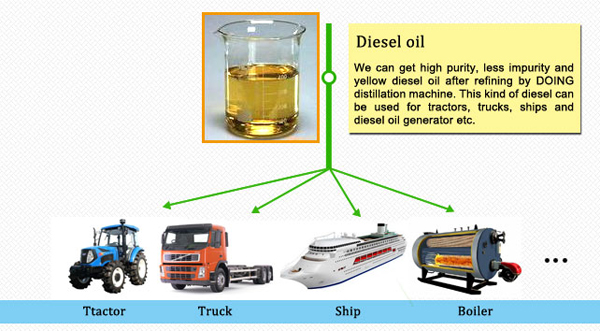

The applications of diesel oil recycled from waste oil recycling to diesel plant:

Waste oil, tire pyrolysis oil and plastic pyrolysis oil are converted into clean diesel oil at a recovery rate of about 85 per cent (depending on the quality of the oil) after being recycled by waste oil recycling to diesel plant. This kind of diesel oil can be used in tractors, trucks, generators, farm machinery, ships, boilers and so on.

The applications of diesel oil from waste oil recycling to diesel plant

The applications of diesel oil from waste oil recycling to diesel plant

The waste oil recycling to diesel plant produced by DOING company can withstand the test of customers in all aspects and has received a lot of customers' favor.

If you have any questions about the waste oil recycling to diesel plant, you can leave a message to us, and the professional engineers of DOING company will give you a satisfactory reply.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications