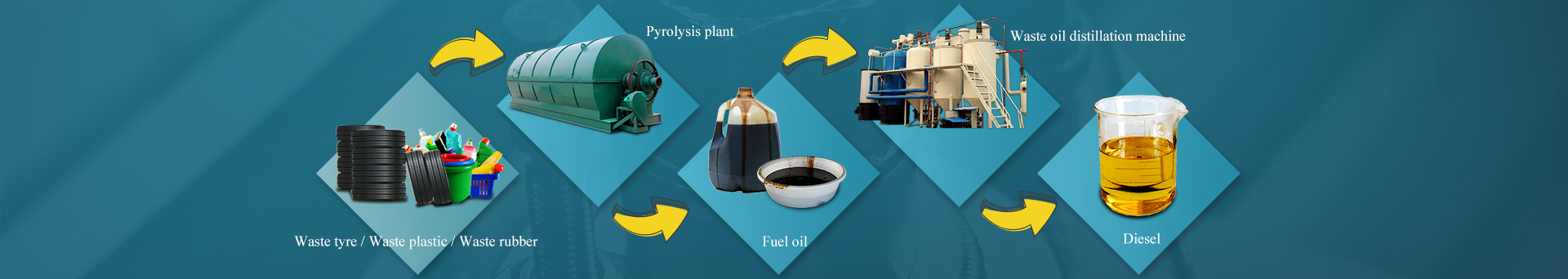

Used motor oil to diesel fuel refinery plant

Used motor oil to diesel fuel refinery plant is also called oil refining machine. It can refine waste oil(waste engine oil,motor oil, tyre oil, plastic oil, etc) to diesel. The oil recovery yield is about 85% ( according to oil quality).

Used motor oil to diesel fuel refinery plant can refine waste oil to diesel

Used motor oil to diesel fuel refinery plant can refine waste oil to diesel

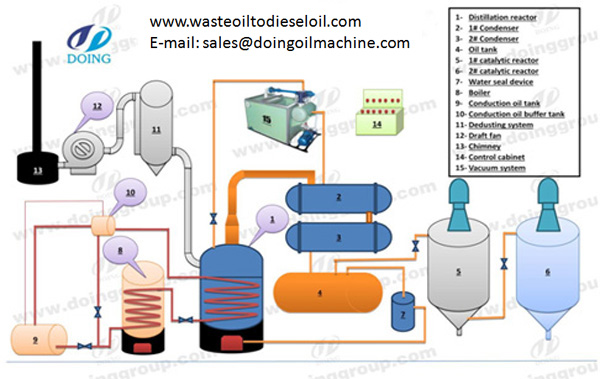

Used motor oil to diesel fuel refinery plant produced by DOING Company is mainly composed of distillation reactor, buffer tank, catalytic tower, cooling system and oil storage tank. Used motor oil to diesel fuel refinery plant uses double heating of heat transfer oil and fuel. The combination of the two methods improves the working efficiency of the used motor oil to diesel fuel refinery plant and the conversion rate from used motor oil to diesel fuel.

Used motor oil to diesel fuel refinery plant installed in China

Used motor oil to diesel fuel refinery plant installed in China

The main working process of used motor oil to diesel fuel refinery plant:

First, the used motor oil is pumped into the distillation reactor, then the used motor oil is rapidly heated in the distillation reactor by heated transfer oil. This heating method can better control the temperature and is conducive to the following operation.

Second, as the temperature increases, the used motor oil produces oil gas and flows into the buffer tank. When the oil gas passes through the buffer tank and controls the temperature, the light components in the used motor oil can be distilled and collected into the distillation tank. Light oils usually contain a strong odor, also known as an odor component. A good oil product will be obtained after collecting the odor component.

Third, as the temperature rises further, the oil gas enters the catalytic tower from the distillation reactor. After the treatment of the catalytic tower, the oil gas is decomposed into small molecules of oil.

Fourth, the small molecules of oil gas are cooled into liquid oil by a cooling system and collected in a storage tank.

Fifth, after all the oil gas has evaporated, the remaining in the distillation reactor is asphalt and it can be directly pumped out by the asphalt pump.

The main working process of used motor oil to diesel fuel refinery plant

The main working process of used motor oil to diesel fuel refinery plant

Quick details about used motor oil to diesel fuel refinery plant:

1> Unique manufacturing and technology with our own formula of our equipment in China.

2> High oil output, about 80%-90%.

3> Good quality end product oil as the substitution of standard diesel oil in usage.

4> Security:

A. Adopting submerged automatic arc welding and weld seam grinding technology.

B. All of the welding will be detected by the inpact tester, x-ray testing and tension testing to ensure the welding quality and the welding shape.

C. Equipped with anti-explosive device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

5> Environmental-friendly:

A. Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

B. Smell during operation: Fully enclosed during the operation.

C. Water pollution: No pollution at all.

6> Energy conservation and low cost on operation:

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as

well as the direct heating system to save energy and cost.

Technical data of used motor oil fuel to diesel refinery plant

| Items | Contents |

| Raw material | Tyre oil, Plastic oil, Raw oil, waste engine oil, used motor oil |

| Structure form | Vertical (easy maintenence,easy slugging) |

| Model | DY-DP |

| 24-hour capacity | 5t-100t… |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| oil out-put oil rate | Around 85% (Depend on the material) |

| Material of reactor | Q345R boiler plate |

| Thickness of reactor | 16mm |

| Reactor rotate speed | 0.4-0.8 turn/minute |

| Mode of cooling | Water cooling |

| Power in total | 4.0-8.0kw |

Final products of used motor oil to diesel fuel refinery plant are diesel and asphalt. The diesel obtained from used motor oil to diesel fuel oil refinery plant can be directly used in tractors,trucks,diesel oil generators etc.

The application of diesel from used motor oil to diesel refinery plant

The application of diesel from used motor oil to diesel refinery plant

After-sale Service:

1.Design the installation drawings according to your site

2.For each set of waste engine oil to diesel machine, one engineer will be sent toguide your installation, test the machine and train your workers.

3.1 year warranty, engineers available to service at any time

4.Periodical call visit, to make sure there is no problem of the equipment

5.Design specific maintenance program according to different situation of yourplant

Henan DOING Mechanical Equipment CO., Ltd is a professional manufacturer and supplier of used motor oil to diesel fuel oil refinery plant with advanced distillation technology. Our plant can ensure you high oil yield and safety; you will get great profit from this project. Welcome your inquiry and visiting.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications