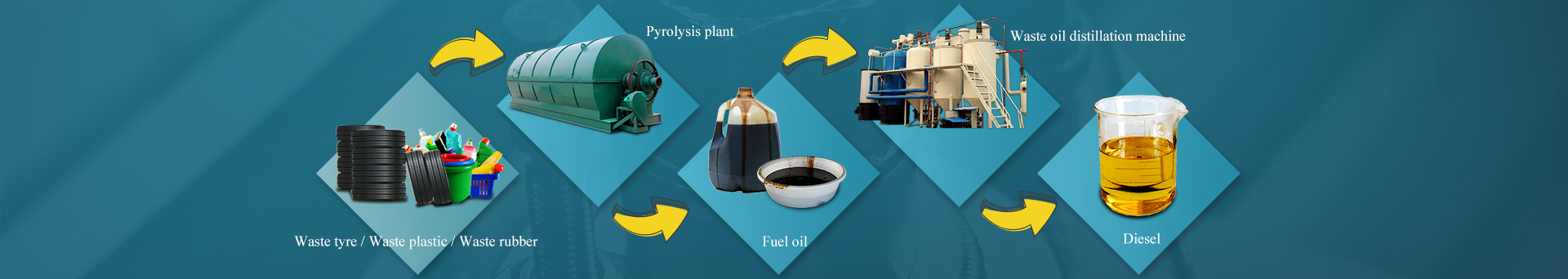

Heavy oil to diesel oil distillation plant

Distillation is a commonly used method for purifying liquids and separating mixtures of liquids into their individual components. Familiar examples include the distillation of crude fermentation broths into alcoholic spirits such as ginad vodka, and the fractionation of crude oil into useful products such as gasoline and heating oil. In the organic lab, distillation is used for purifying solvents and liquid reaction products.

It’s easy to produce waste residue and bad smelling by traditional vitriol distilling, which will bring potential secondary pollution, moreover, it’s easy to change the color to black and produce the odor due to the recycled heavy oil react with the oxygen. But after we use the alkaline complex catalyst refines the heavy oil, the recycled heavy oil havn't change the color and havn't create the odor. What’s more important, you can use the resid to be as the fuel to heating the heavy oil, without any pollution. And the plant is easy to operate, only 1-2 workers can control the plant.

Heavy oil to diesel oil distillation plant

Heavy oil to diesel oil distillation plant adopts our exclusive patent heating technologies. The entire plant applies the pure physical working principle, even heating and self-balancing flow, it has no damaging of oil substances.

1 What thickness specifications does a reactor have in general?

The furnace’s thickness of the reactor can be 14mm, 16mm, 18mm and 20mm. But some factories send the reactor with different thickness, so some reactors are cheap.

2 What material is the reactor? And what characteristic is it respectively?

The material used by reactor mainly is boiler steel plates, their materials are divided into Q245R and Q345R, the price of the two steel plates are not different too much.

All the reactors our company produced are the boiler steel plates produced by Henan DOING company. Each steel plate has a batch number, and we have certificate of material, which can be searched on the Internet.

Q245R: boiler steel material, can resist the temperature at 400℃, large scale degree, resists burning and is made of professional boiler steel.

Q345R: its former name is “16MnR” boiler steel plate, using temperature ranges from minus 20℃to 480℃.

It’s easy to produce waste residue and bad smelling by traditional vitriol distilling, which will bring potential secondary pollution, moreover, it’s easy to change the color to black and produce the odor due to the recycled heavy oil react with the oxygen. But after we use the alkaline complex catalyst refines the heavy oil, the recycled heavy oil havn't change the color and havn't create the odor. What’s more important, you can use the resid to be as the fuel to heating the heavy oil, without any pollution. And the plant is easy to operate, only 1-2 workers can control the plant.

Heavy oil to diesel oil distillation plant

1 What thickness specifications does a reactor have in general?

The furnace’s thickness of the reactor can be 14mm, 16mm, 18mm and 20mm. But some factories send the reactor with different thickness, so some reactors are cheap.

2 What material is the reactor? And what characteristic is it respectively?

The material used by reactor mainly is boiler steel plates, their materials are divided into Q245R and Q345R, the price of the two steel plates are not different too much.

All the reactors our company produced are the boiler steel plates produced by Henan DOING company. Each steel plate has a batch number, and we have certificate of material, which can be searched on the Internet.

Q245R: boiler steel material, can resist the temperature at 400℃, large scale degree, resists burning and is made of professional boiler steel.

Q345R: its former name is “16MnR” boiler steel plate, using temperature ranges from minus 20℃to 480℃.

| Technical parameter of heavy oil to diesel oil distillation plant with production technology | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | heavy oil, motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the plant service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95%diesel oil |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

| Technical parameter of heavy oil to diesel oil distillation plant with production technology | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | heavy oil, motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the plant service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95%diesel oil |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications