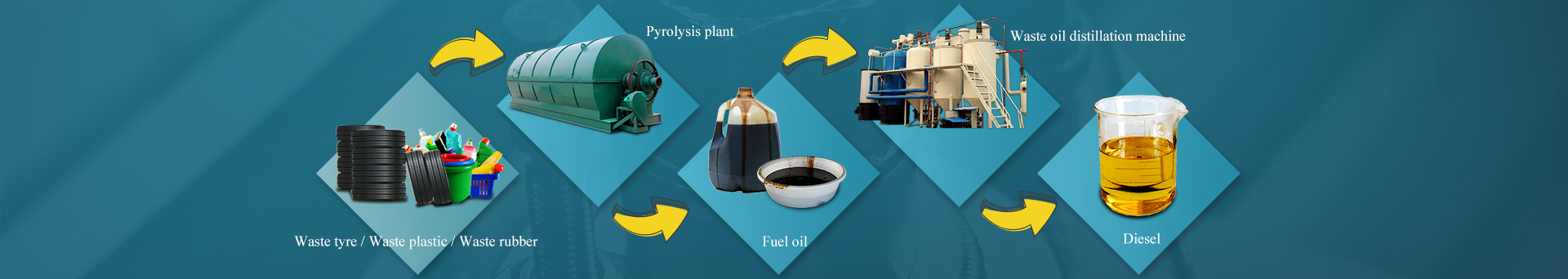

Waste oil into diesel oil equipment

Waste Lubricant oil

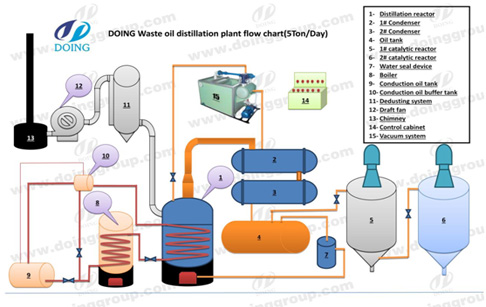

Waste oil into diesel oil equipment working process

1. Using high-temperature distillation, part of the distillation of the fuel flow into the tank, the other part of the oil and gas into the condensing system.

2. After being condensed, liquefied into refined oil into the tank.

3. The refined fuel will eventually be degreased, decolorized. Get the final refined oil.

Waste oil into diesel oil equipment

1.Large capacity

According to customer needs we can customize the equipment 10-100 tonnage. Of course, if the customer needs can also be customized small pilot production equipment.

2. Slag easy

Reactor vertical design, instead of horizontal design, this design can facilitate the removal of combustion residues in the furnace.

3.Fast heating

Waste oil to diesel equipment designed to double the heating system, both the reactor base heating, but also the thermal system heating. Can shorten the heating time, improve operating efficiency.

Waste oil into diesel oil equipment Technical parameter

| Technical parameter of waste oil into diesel oil equipment | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Waste oil into diesel oil equipment final products application

1. Refined oil: mainly used in diesel generators, light fuel, heavy machinery.

2. Asphalt: can be used directly for paving, asphalt plant can also be used for refining.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications