Waste oil to diesel regeneration machine

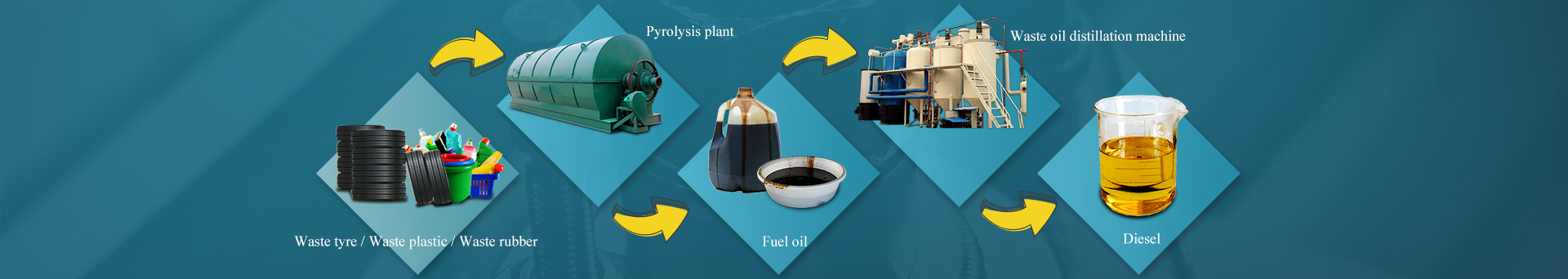

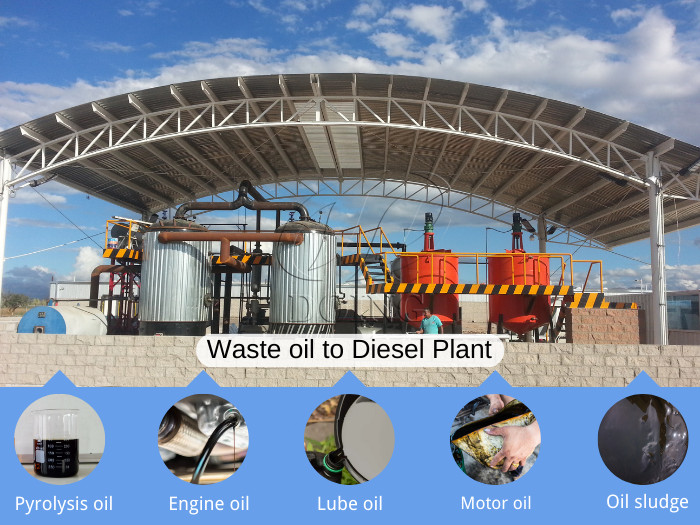

Waste oil to diesel regeneration machines is also called waste oil refinery plant, which can convert waste oil, crude oil, pyrolysis oil, etc. to diesel, achieving environmental and economic profits.

1. Two types of DOING waste oil to diesel regeneration machine

Over the past 13 years, DOING has been committed to enhancing the technology of waste oil to diesel regeneration machines to meet customers' various demands; now DOING has researched two types of waste oil to diesel regeneration machines:

1) The common waste oil to diesel regeneration machine

The common waste oil to diesel regeneration machine of DOING

The common waste oil to diesel regeneration machine of DOING

This type uses the liquid catalysts (acid and alkali) to purify the waste oil, which needs a lower investment and install and operate easily. And if you can obtain the acid and alkali catalysts easily and cheaply, this type is more suitable for you.

2) The new design waste oil to diesel regeneration machine

The new design waste oil to diesel regeneration machine of DOING

The new design waste oil to diesel regeneration machine of DOING

This type uses solid catalysts, which can be bought from DOING directly, to purify the waste oil. This type also has a higher working efficiency, safety and automation. So if you have difficulty purchasing the liquid catalyst and want to improve the working efficiency and save time and labor, this type is a good choice.

Although these two types of waste oil to diesel regeneration machines have different designs and technology, they have a similar working process and can obtain the same good quality non-standard diesel. The following is a brief introduction about the working process of the waste oil to diesel regeneration machine:

Pour the waste oil into our vertical distillation reactor, heat the waste oil in a certain temperature to remove impurities, and further distill the waste oil into oil gas. After condensation and catalysis, the oil gas will be cooled into diesel. If you want to further purify, we can also provide the decolorization and deodorization system to refine the obtained diesel deeply. The following is the 3D running video of DOING waste oil to diesel regeneration machine:

2. The obtained final products and applications

In general, with the waste oil to diesel regeneration machine, we can obtain 80% -85% yellow or amber diesel, 5% -10% asphalt and 5% combustible gas, which all have multiple applications to generate huge profits:

1) Diesel: Diesel can be used in boiler heating, generator, trucks, ships, heavy oil machinery, etc.

2) Asphalt: The asphalt can be used for paving or refinery.

3) Combustible gas: The combustible gas can be used to heat the reactor directly or other heating uses.

Multiple applications of obtained final products

Multiple applications of obtained final products

3. Environmental and economic benefits of waste oil to diesel regeneration machine

1) Environmental benefits

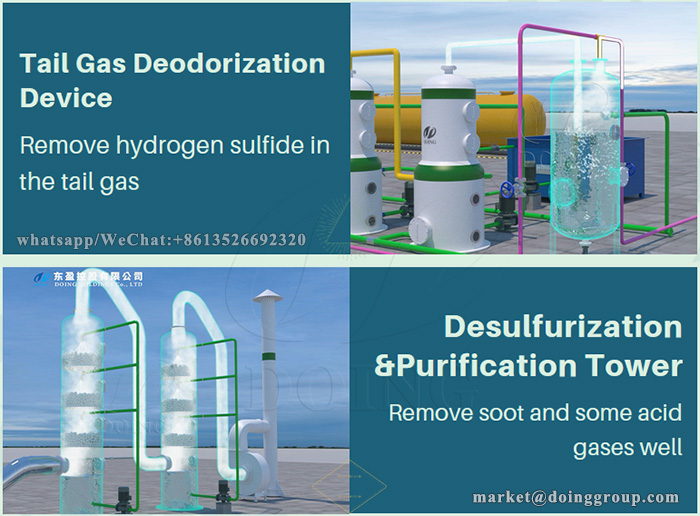

Waste oil is hazardous waste and is a poisonous and harmful substance. Once used improperly, it will cause serious harm to human health, soil, water, etc. The traditional landfill and incineration will cause serious environmental problems. While waste oil to diesel regeneration machine can recover waste oil environmentally friendly. And DOING waste oil to diesel regeneration machine is equipped with some environmental protection systems, such as the tail gas cleaning system and desulfurization tower, which can purify the produced tail gas and smoke to avoid air pollution. In addition, our cooling system adopts circulate water, avoiding water pollution.

Environmental protection system of DOING waste oil to diesel regeneration machine

Environmental protection system of DOING waste oil to diesel regeneration machine

2) Economic benefits

Apart from the generated environmental benefits, the waste oil to diesel regeneration machine can recover waste oil to useful products, which have multiple applications to generate huge profits. The following is the profits analysis of DOING waste oil to diesel regeneration machine based on our market survey and customers' feedback (take our 5TPD waste oil to diesel regeneration machine as an example):

| Profit analysis of one set DOING 5TPD Waste oil to diesel regeneration machine | |||

| Cost for one batch | |||

| Item | Consumption | ||

| Crude oil | 5T | USD1770 | |

| Heating fuel consumption | 500kg | 0.5*USD300=USD150 | |

| Waster&Electricity consumption | 24Kw | (24Kw/h*10h)*USD0.2Kw/h=USD48 | |

| Catalyst | USD100 | ||

| Workers’ salary | USD100 | ||

| Total cost | USD2168 | ||

| Return for one batch | |||

| Item | Consumption | ||

| Diesel | 4.25-4.5T | 4.25*USD870.24=USD3698.52 | |

| Bituman | 0.5-0.75T | 0.5*USD108=USD54 | |

| Total income | USD3752.52 | ||

| Profit | |||

| Daily profit | USD1,584.00 | ||

| Monthly profit(20 days) | USD31,690.00 | ||

| Annual profit(10 months) | USD316,904.00 | ||

DOING has researched the technology of waste oil to diesel regeneration machines for over 13 years and our machines have won the trust and praise of many customers, so if you want to carry out the waste oil to diesel regeneration machine project, welcome to contact us, our sales manager will help make the suitable schemes to contain most profits.

Prev: Nothing

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications