What is Pyrolysis Plant?

Pyrolysis Plant :

Pyrolysis plant here means converts waste plastic and waste tyres into pyrolysis products like pyrolysis oil, pyrolysis gas, carbon black. Pyrolysis plant offers new business opportunities like:

1. Recycling

2. Waste to energy

3. Energy recovery from waste

4. Waste to electricity

5. Pollution control

6. Solid waste management

7. New and renewable energy

8. Environment protection

Today's world generates millions of tons of waste plastic and waste tyres every month. Plastic and tyre pyrolysis can convert this waste into energy worth billions of dollars. Pyrolysis plant is an upcoming industry that will fuel tomorrow's growth and protect environment by cleaning waste plastic and waste tyres dumping yard off.

Waste Plastic & Waste Tyres Pyrolysis

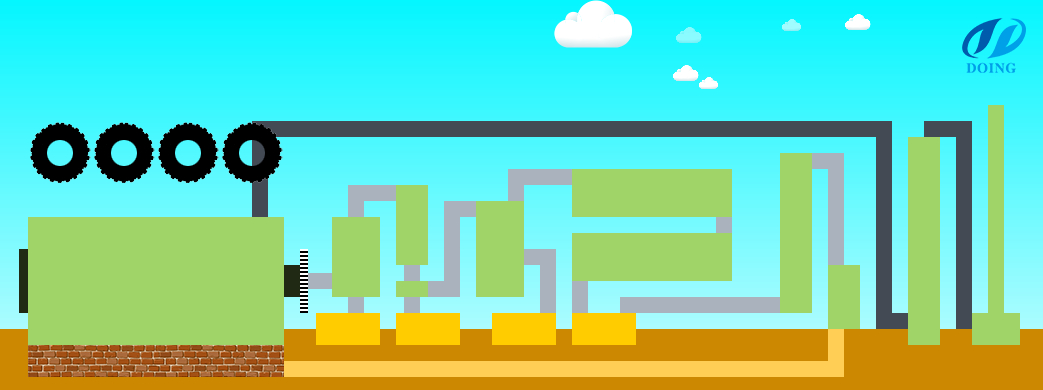

Waste plastic pyrolysis or waste tyres pyrolysis is: the process of converting waste tyres and plastic to industrial oil, like pyrolysis oil, carbon black and hydrocarbon gas. Under high temperature, the waste tyres and plastic in a sealed space will produce oil gas, oil gas goes through the sealed pipe into the following condensers, by recycling water, cooling down oil gas to oil, and this oil called pyrolysis oil.

Waste tyres pyrolysis plant

Waste tyres pyrolysis is process of converting waste tyres into usable fuels like Pyrolysis Oil, Carbon black and Pyrolysis Gas. Pyrolysis Oil and Carbon black are sold to those heavy industries, like cement factory, brick factory, glass factory, milling factory etc. Pyrolysis gas is consumed to generate heat required for pyrolysis of tyres.

Waste Plastic Pyrolysis:

Waste plastic pyrolysis plant

Compared to tyres, waste plastic pyrolysis is offers additional challenges like:

1. Content of unpredictable amount of moisture and metal/non-plastic particles

2. Large variation in raw material specification

3. In reactor, plastic has tendency of sticking in for of coke leading to reduced heat exchange

4. Faster rate of pyrolysis reaction. Needs careful design of reactor

Pyrolysis Raw materials:

Variety of polymer waste material is suitable as a raw material. Raw Material Specifications and its different oil yield.

Below is a list of suitable raw materials for pyrolysis plant:

1. Waste Plastic

2. Mixed plastic (HDPE, LDPE, PE, PP, Nylon, Teflon, PS, ABS, etc)

3. Electronic scrap

4. Mixed waste plastic from waste paper mill

5. Multi Layered Plastic

6. Waste tires

7. Rubber

8. Plastic or rubber parts from vehicles

9. Waste engine oils etc.(used by oil distillation machine)

At DOING Company, we have successfully established fully automatic type plastic pyrolysis plants, waste plastic to oil plant, waste oil distillation machine etc. We have developed sustainable machinery design and catalyst technology to support industrial pyrolysis of plastic and tyre waste. Machinery required for plastic pyrolysis is same as mentioned in tyres pyrolysis.