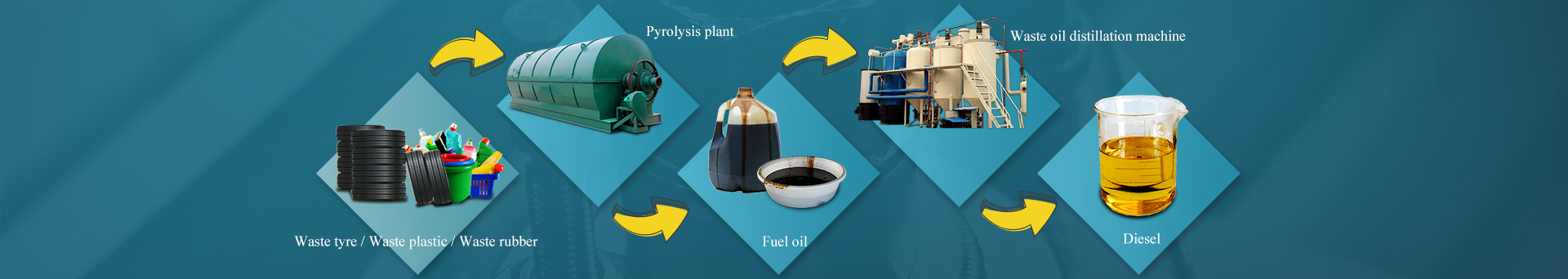

Pyrolysis oil to diesel distillation plant

Pyrolysis oil is a kind of heavy oil produced by waste pyrolysis plant. It mainly refers to tyre oil(TPO/TDF), plastic oil, rubber oil, Bio-oil, etc. Pyrolysis oil is mainly used as a high calarific alternative fuel oil for various kinds of heating furnaces, boilers, heavy oil power plants, heavy industries, etc.

But if pyrolysis oil is refined by pyrolysis oil to diesel distillation plant, the diesel can be used directly in transport trucks, ships, boats, diesel generators, tractors, agricultural vehicles, heavy machinery, etc. The quality, smell, color of pyrolysis plant can be further improved. Making diesel oil from pyrolysis oil has broad market prospects and huge economic benefits.

Tire plastic pyrolysis oil to diesel distillation plant

Tire plastic pyrolysis oil to diesel distillation plant

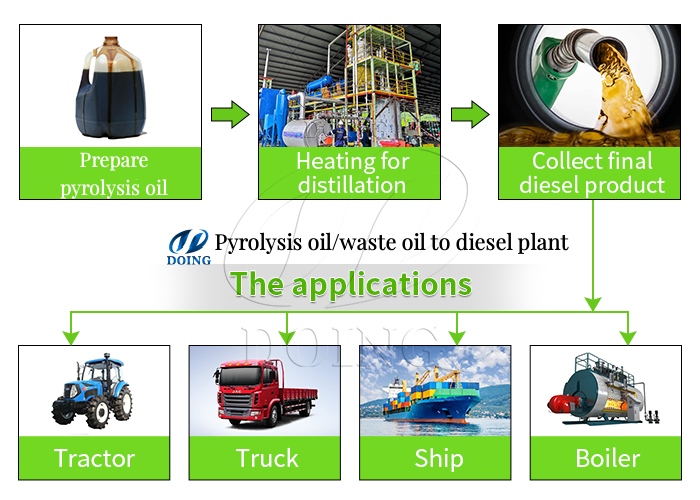

Our DOING pyrolysis oil to diesel distillation plant can process pyrolysis oil, waste engine oil, used motor oil, old lube oil, etc. into diesel. It is the latest design which is unique in China market. The pyrolysis oil to diesel conversation rate can reach 85%.

The whole pyrolysis oil to diesel distillation system consists of distillation reactor, fractionating tower, condenser, catalyst and purification system, oil storage tank, etc.

Here is the 3D Video that demonstrates the pyrolysis oil to diesel distillation plant working process: heating the distillation reactor---pyrolysis oil distillation---oil gas generation-cooling into fuel---further refining with catalyst---obtaining diesel fuel.

Our pyrolysis oil to diesel distillation plant has some advantages.

1. Great design: Vertical reactor with indirectly heating system is very efficient and reasonable. It is easy to clean the bottom of the distillation reactor.

Pyrolysis oil to diesel distillation plant design details

Pyrolysis oil to diesel distillation plant design details

2. Long service life: Indirect heating will prolong the service life of reactor; and the distillation reactor is made of national standard certified high-quality steel, which is durable.

3. High processing efficiency:

(1)We have the fast heating system to offer heat for pyrolysis oil to diesel distillation process quickly. Our distillation reactors are also equipped with thermal coils, which can increase the contact area and speed up distillation efficiency.

(2)After finishing one batch of pyrolysis oil distillation, we will pump the oil into odor and color removal tank. Then it can start to pump fuel oil to reactor for another batch. And we also have the new solid catalyst design pyrolysis oil distillation plant. The distilled oil gas will be directly catalyzed then cooled into diesel fuel. The whole pyrolysis oil to diesel distillation process is more automatic. So we say it is continuous work.

Two types of pyrolysis oil to diesel distillation plants

Two types of pyrolysis oil to diesel distillation plants

4. Better oil quality: We Henan Doing Company offers different purification systems for customers to choose from. The oil color can be brown yellow or lighter yellow according to customers' requirements.

5. Environmental protection: The exhaust gas generated in the pyrolysis oil to diesel distillation process will be purified then be discharged up to the standards.

Till now we have successfully installed pyrolysis oil to diesel distillation plants in different countries and won good feedback from our customers because of high quality and competitive prices.

Pyrolysis oil to diesel distillation plant projects installed by DOING

Pyrolysis oil to diesel distillation plant projects installed by DOING

Pyrolysis oil to diesel distillation plant technical data:

| Items | Contents |

| Raw material | pyrolysis oil, tyre oil, Plastic oil, Raw oil, waste engine oil, waste motor oil |

| Structure form | Vertical (easy maintenence,easy slugging) |

| Model | DY-DP |

| 24-hour capacity | 100KG-14+T/D… |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| oil out-put oil rate | Around 85% (Depend on the material) |

| Material of reactor | Q345R/Q245R boiler plate, 304/306/310s stainless steel |

| Thickness of reactor | 16mm |

| Reactor rotate speed | 0.4-0.8 turn/minute |

| Mode of cooling | Water cooling |

| Power in total | 4.0-8.0kw |

Final product usage of pyrolysis oil to diesel distillation plant:

(1)Diesel can be directly used to tractors ,trucks, diesel oil generators, ligh oil boiler/heater, agriculture machinery, heavy machinery, etc.

Applications of diesel extracted from pyrolysis oil distillation plants

Applications of diesel extracted from pyrolysis oil distillation plants

(2) Asphalt can be directly used for paving or sold to asphalt refining factory.

All around technical services and after-sale services:

1. Design the installation drawings according to your site;

2. For each set of pyrolysis oil to diesel distillation plant, one engineer can be sent to guide your installation, test the machine and train your worker based on your requirement;

3. 1 year warranty, engineers available to service at any time;

4. Periodical call visit, to make sure there is no problem with the equipment;

5. Design specific maintenance program according to different situation of your plant;

Henan DOING Environmental Protection Technology CO., Ltd is a professional manufacturer and supplier of pyrolysis oil to diesel distillation plant with advanced distillation technology. Our plant can ensure you high oil yield and safety; you will get great profit from this project. Welcome your inquiry and visiting.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications