Waste plastic to fuel conversion pyrolysis plant

Waste plastic to fuel conversation pyrolysis plant

Waste plastic to fuel conversation pyrolysis plant

Waste Plastic to Fuel Conversion Pyrolysis Plant is an innovative solution designed to transform waste plastic materials into valuable products such as fuel oil, carbon black, syn-gas, metal, etc. It offers the benefits of reducing plastic waste, generating alternative energy, and lowering carbon emissions compared to traditional plastic disposal methods.

1. What Problem Does Waste Plastic to Fuel Conversion Pyrolysis Plant Address?

The rapid rate of plastic consumption throughout the world has led to the creation of increasing amounts of waste plastic and this in turn poses greater difficulties for disposal. Nowadays, the largest amount of plastic wastes is disposed of by land filling, and incineration, which will seriously pollute the soil, water and air. So, Environmental pollution increases day by day in everywhere. Traditional disposal methods, such as landfilling and incineration, are no longer sustainable due to the growing volume of waste and their negative impact on the environment.

Waste plastic pyrolysis plant provides a sustainable and efficient way to address plastic waste pollution problems by converting this waste into usable resources, while also helping to mitigate the environmental impact of plastic pollution.

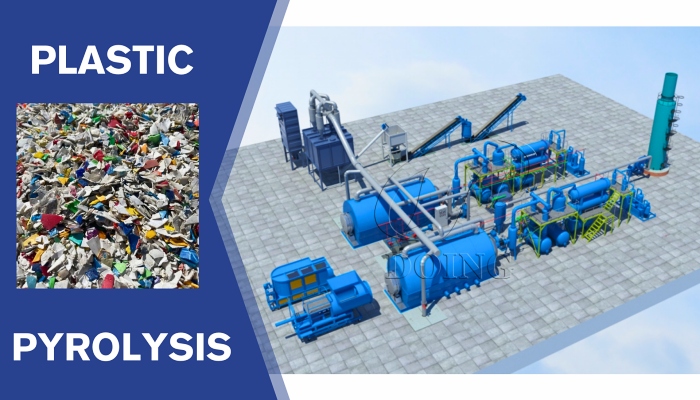

3D Drawing:

Waste plastic to fuel conversation pyrolysis plant 3D drawing

Waste plastic to fuel conversation pyrolysis plant 3D drawing

DOING Waste Plastic to Fuel Conversion Pyrolysis Plant can process a wide variety of plastic waste except PVC and PET materials, including used laundry bottles, shampoo bottles, soft drink and water bottles, juice cups, foam products, shopping bags, and plastic packaging materials, agricultural plastic films, acrylic plastic, epoxy resin, woven bags, e-waste plastic&metal composite materials, aluminum plastic composite materials, etc. This flexibility allows the plant to handle diverse sources of plastic waste, making it an ideal solution for both urban and industrial applications.

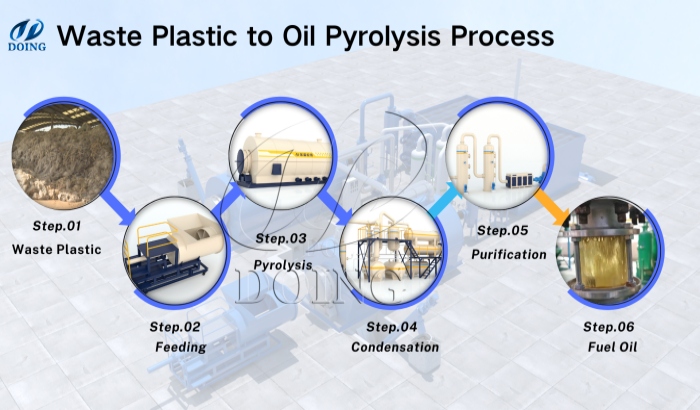

2. What is the Waste Plastic to Fuel Conversion Process?

Pyrolysis is a thermal treatment process that decomposes waste plastic at high temperatures in the absence of oxygen. Waste Plastic to Fuel Conversion Pyrolysis Plant works by heating mixed plastic waste, such as HDPE, LDPE, PP, PS, ABS, plastic composite materials like aluminum plastic, to break down the polymer chains. DOING Waste Plastic to Fuel Conversion Pyrolysis Plant utilizes an advanced pyrolysis conversion process, the core steps of which are as follows:

Waste plastic to fuel oil conversation pyrolysis plant process steps

Waste plastic to fuel oil conversation pyrolysis plant process steps

①Feedstock Pretreatment: If a semi-continuous or fully continuous plastic pyrolysis plant with a slightly higher degree of automation is used, the collected mixed plastic waste is typically cleaned and crushed. This step ensures the purity and uniformity of the feedstock entering the pyrolysis reactor, laying the foundation for efficient pyrolysis and conversion.

②Pyrolysis Cracking: In a closed, oxygen-free (or low-oxygen) environment, plastics undergo chemical decomposition at high temperatures (typically between 300℃and 500℃). Long polymer chains are broken down into smaller molecules, which then vaporize to form pyrolysis gas.

③Product Separation and Condensation:

Gas Fraction: Uncondensed pyrolysis gas is rich in combustible gases (such as methane, ethane, and propane). These gases can be recovered and used to power the pyrolysis process, achieving energy self-sufficiency and further reducing operating costs.

Liquid Fraction: The pyrolysis gas passes through an efficient condensation system and is cooled into a liquid. This liquid is the derived plastic pyrolysis fuel oil (plastic oil), primarily composed of paraffins, olefins, naphthenes, and aromatics.

Solid Residue: The solid residue deposited after cooling is also known as carbon black.

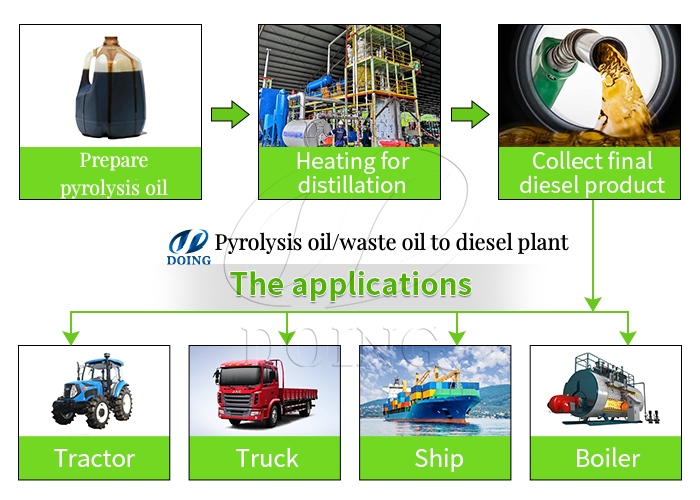

④Refining and Purification (Optional): The initial fuel oil and carbon black are processed in the pyrolysis oil refining machine through distillation, catalytic refining, and filtration processes to improve the quality of plastic pyrolysis oil. This allows for the production of non-standard diesel fuel with improved color and quality, meeting the needs of a wider range of market applications, such as large-scale heavy industrial machinery, boilers, diesel generators, ships, boats, tractors, trucks, etc.

Plastic pyrolysis oil to diesel refining machine

Plastic pyrolysis oil to diesel refining machine

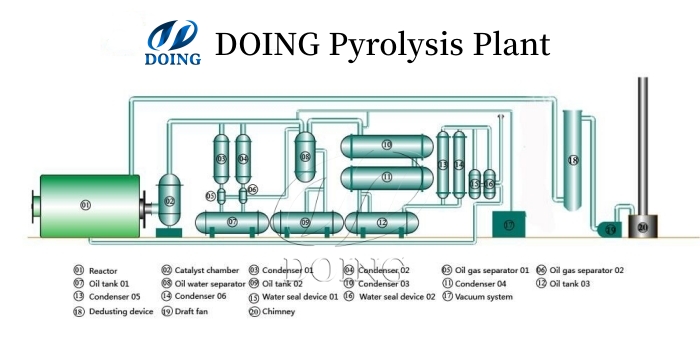

3. Plastic to Fuel Conversation Pyrolysis Plant Design and Technical Parameters

The necessary equipments for Waste Plastic to Fuel Conversation Pyrolysis Plant are mainly consisted of auto-feeder, pyrolysis reactor, catalyst chamber, oil water separator, condenser units, vacuum device, cooling water, fuel container/oil tank, heating combustion system, safety device, dedusting system, exhaust gas recycling system and operating system. Together, these core components improve energy utilization, reduce operating costs, and ensure safe, reliable, and continuous operation throughout the waste plastic to fuel conversion process.

| Introduction of main parts and features of waste plastic to fuel conversion pyrolysis plant | |

| Reactor | 1. Made by Q245R boiler plate. Also can choose Q345R, OR 304 AND 306 stainless. |

| 2. Auto-welding both inside and outside | |

| Auto-feeder | 1. 60 ton hydraulic pressure |

| 2. Can feed all types of materials | |

| 3. Save labor and save time | |

| Catalyst chamber | 1. Improve oil yield and oil quality |

| 2. Reduce the speed of oil gas so that it can be better cooled | |

| Oil-water separator | 1. Separate oil and water |

| 2. Collect heavy oil | |

| 1. Water sealing design keep safety | |

| Condenser | 1. The oil gas is cooled separately by small pipes inside condenser |

| 2. Light oil is collected here | |

| Vacuum device | Keep machine running under normal pressure |

| Anti-back fire device | 1. Recycle residual gas to furnace as fuel |

| 2. Water sealing design prevent tempering | |

| Dust removal device | Dispose of flue gas caused by using coal, wood, oil or natural gas. |

Among them, pyrolysis Reactor and Condensers are significant role in pyrolysis process.

The function of reactor is to break down the long chain hydrocarbon composed in various plastics. The reactor has been designed as a cylindrical shell for the solid waste pyrolysis. DOING plastic pyrolysis reactor features high thermal efficiency, uniform heating, and durable steel materials construction, ensuring stable performance and a long service life under continuous high-temperature operation. As a world leading pyrolysis plant manufacturer, Doing Company has conducted meticulous design for the sealing performance, transmission design, and welding process of the pyrolysis equipment.

The condenser is provided to cool and condense the gases evolved out from the pyrolyser. As a result of cooling, the condensable gases become liquid which is called pyrolytic oil. DOING plastic pyrolytic fuel oil condenser system adopts a multi-stage cooling structure with large heat exchange area and rapid condensation efficiency, guaranteeing higher recovery of fuel oil and purer output.

DOING Certificates:

Plastic pyrolysis plant manufacturer---DOING Company certificates

Plastic pyrolysis plant manufacturer---DOING Company certificates

4. Final Products of Waste Plastic to Fuel Conversion Pyrolysis Plant

The applications and yields of final products such as oil, carbon black, and metal extracted from waste plastic recycling pyrolysis process are as follows:

①Fuel Oil (30% to 85%)

Plastic extracted pyrolysis fuel oil applications

Plastic extracted pyrolysis fuel oil applications

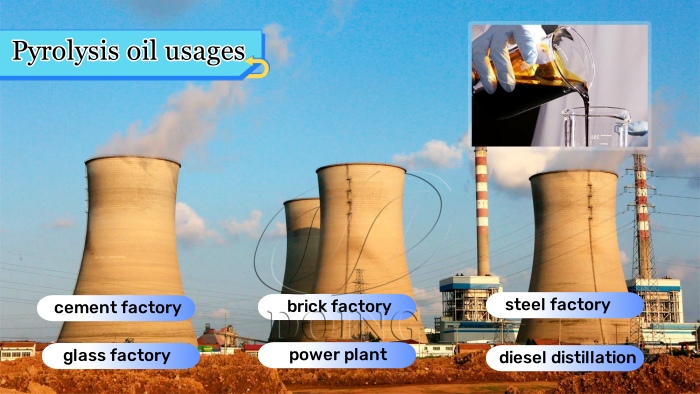

The main application of oil products produced by plastic to fuel conversion pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory, glass factory, cement factory, ceramic factory. This liquid fuel can be used in industrial applications or further refined into diesel, making it a valuable energy resource.

Noted: The pyrolysis fuel oil yield is affected by waste plastic raw materials. Different plastics contain different amounts.

| Approx oil yield off different raw materials | |

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Leftovers of paper | Wet 15-20%,dry 60% |

| House garbage | 35%-50% |

| Plastic cable | 80% |

| Plastic bag | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Big tires | 45%-50% |

| Small tires | 35%-40% |

| PVC | Not suitable |

| PET | Not suitable |

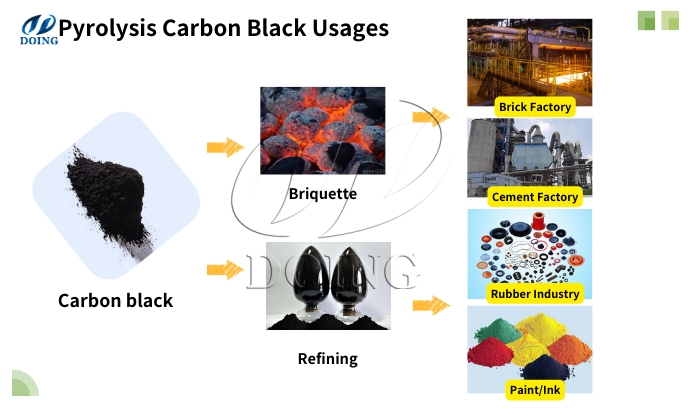

②Carbon Black (30% to 35%)

A high-quality material used in various industries, including rubber production, automotive parts, and electronics, such as electric cable jacketing, black nylon bag, rubber additive.

Plastic pyrolysis carbon black applications

Plastic pyrolysis carbon black applications

③Gas (About 10%)

We get about 10% pyrolytic gases during waste plastic pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the plastic pyrolysis reactor and we can use exceed gases for other heating application. It is a supplementary energy source, enhancing the pyrolysis system’s efficiency and sustainability.

④Metal(Output rates depend on plastic materials)

If the plastic pyrolysis feedstocks are plastic composite materials, such as aluminum plastic, e-waste PCB boards, etc, metals like aluminum and copper can be recovered. These metals can be used in metal smelting and recasting, electronics and electrical manufacturing, and other industries.

5. What Benefits Does Waste Plastic to Fuel Conversion Pyrolysis Plant Bring?

Environmental Impact Reduction: By converting plastic waste into fuel and other useful products, the pyrolysis process helps reduce the environmental impact of plastic pollution. It prevents plastic waste from ending up in landfills or incinerators, thus minimizing harmful carbon emissions and waste accumulation.

Energy Production: The fuel oil produced can be used as an alternative energy source, reducing dependence on traditional fossil fuels and contributing to a more sustainable energy future.

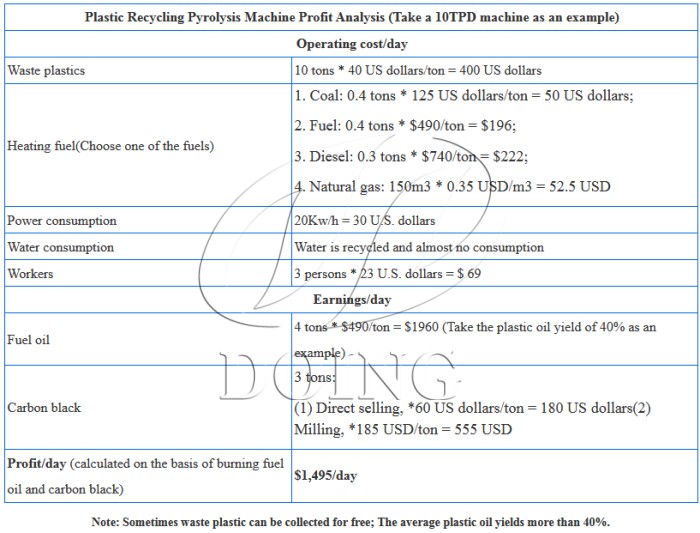

Economic Benefits: The conversion of waste plastic into valuable products like fuel oil and carbon black creates new business opportunities and helps reduce costs associated with plastic disposal and waste management.

Plastic to fuel conversation pyrolysis plant profit analysis

Plastic to fuel conversation pyrolysis plant profit analysis

Sustainability: DOING waste plastic to fuel conversation pyrolysis plant operates in an energy-efficient manner, with the ability to recycle the gases generated during the process to power the system, further enhancing its sustainability.

In an era where plastic waste is rapidly accumulating and the need for sustainable solutions is more urgent than ever, the Waste Plastic to Fuel Conversion Pyrolysis Plant stands as an effective equipment for transforming waste into valuable resources. If you want to invest in our pyrolysis plant today and be part of the solution to reduce plastic waste, promote environmental sustainability, and generate valuable products from waste. Contact us today to request a quote and discover how we can help you transform plastic pollution into profit.

contact us

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications