Now in the market, there are mainly two designs of distillation machine. One is horizontal old design and the other one is vertical new design. Now our distillation machine is the vertical new design with unique heating method. Let me show you the advantages of our distillation machine below.

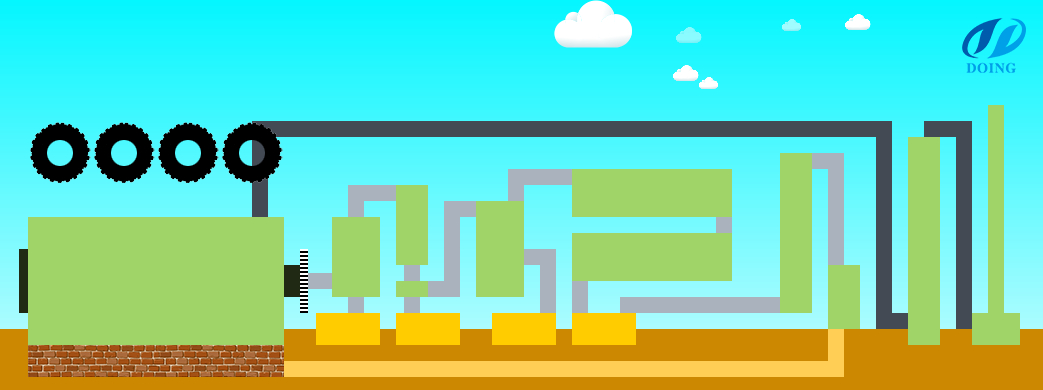

Firstly, please check the flow chart and the picture of our distillation machine below:

Distillation machine 01

Distillation machine 02

Then let me introduce you the advantages of our distillation below:

1. Fast heating

Our distillation machine adopts unique heating method - conduction oil heating. For your better understanding, please check the structure inside the boiler and the reactor below:

Distillation machine 03

You can see from the picture there are many circle pipes inside the boiler and the reactor. And inside the circle pipes, it’s conduction oil, which can be heated to more than 400℃ to heat the crude oil inside the reactor. And there is a stirrer in the middle of the circle pipes which can keep the heating very evenly. Even after one batch heating, the conduction oil is still very hot, which can be used for next batch without heating again. This way, our distillation machine can process 3 batches without stop, which can increase the efficiency greatly.

By comparison, the old design distillation machine is just like the pyrolysis machine design. Heating is just from the bottom of the reactor, which is very slow. Feedbacks from our customers that it takes 36 hours to heat 3 T oil. It wastes too much time.

2. Convenient slagging

From the distillation process, except that we can get diesel product, there is also a byproduct – asphalt which will left in the reactor after distillation process. As we all know that asphalt is liquid when it’s hot and will become sold after cooling. So we need to discharge it when it’s hot. For our vertical design reactor, you can just open the slagging door in the bottom of the reactor after distillation process is ok. It’s easy to discharge.

But for old horizontal design, it’s from a small front door, like the picture below:

Distillation machine 04

Do you think it’s easy to discharge the hot asphalt from the small door in the picture? Of course we all know the answer is no. Because the reactor is horizontal design and the door is small, which you can only use a tool to discharge the asphalt. Since when discharge, the asphalt should be very hot, which is very dangerous when operation. But after it becomes solid, it’s more difficult to discharge. So the old design distillation machine is going to be out of market soon.

If you like to know more about our distillation machine, please feel free to contact us.